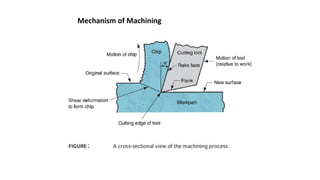

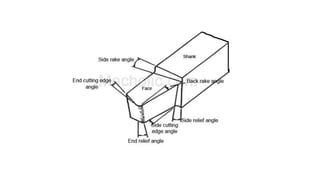

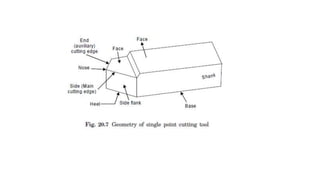

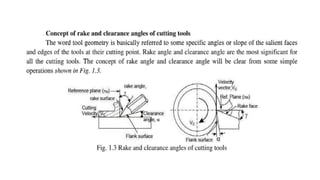

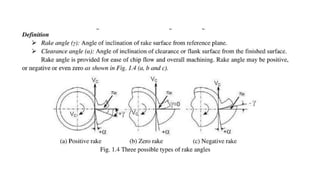

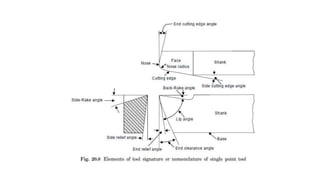

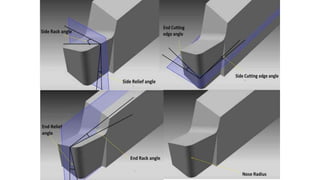

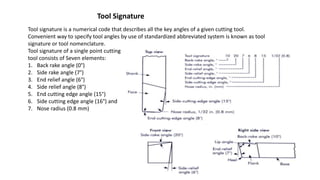

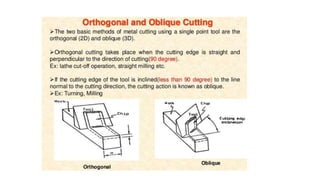

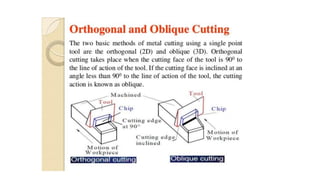

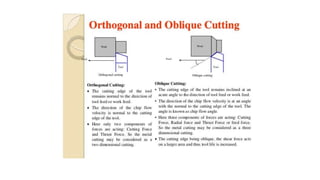

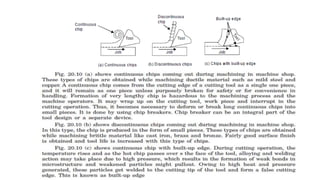

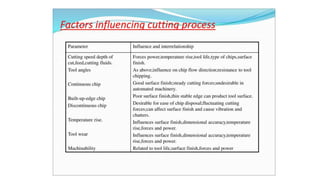

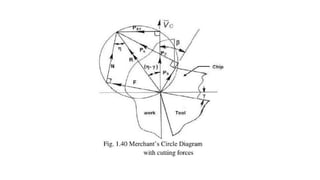

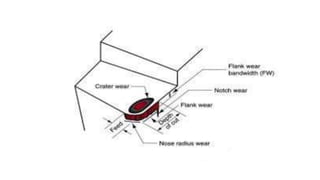

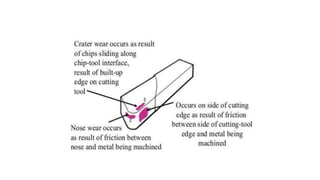

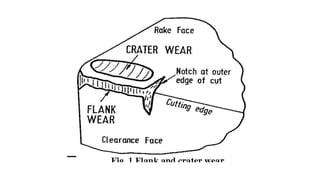

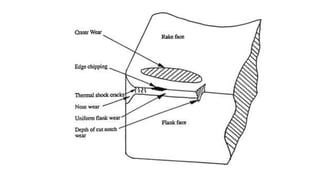

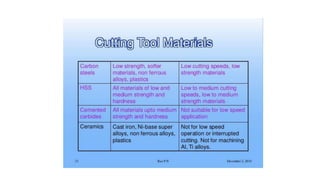

The document discusses the objectives and modules of a course on metal cutting and machine tools. The objectives include studying material removal processes, learning about lathes, milling machines, drilling, broaching, and gear cutting, and gaining knowledge of CNC machine tools and advanced machining methods. The modules cover theory of metal cutting, lathes, reciprocating machines, milling, drilling/broaching/gear cutting, finishing processes, and CNC/modern machining. Key aspects of metal cutting discussed are the geometry of single point cutting tools, chip formation, forces, tool wear, and cutting fluids.