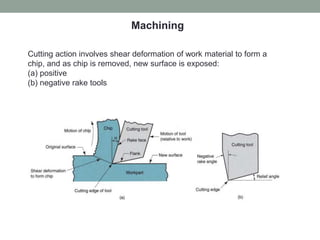

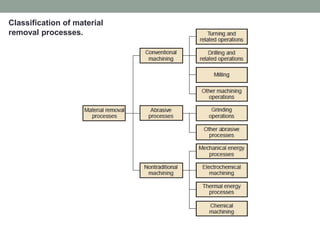

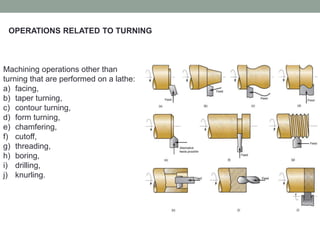

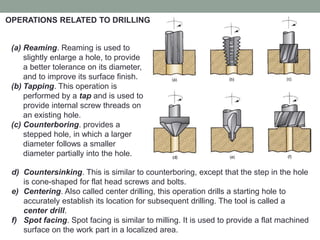

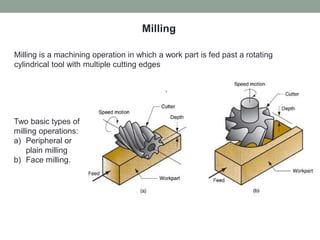

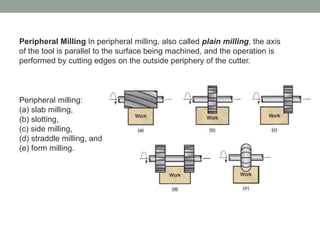

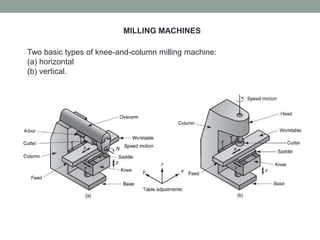

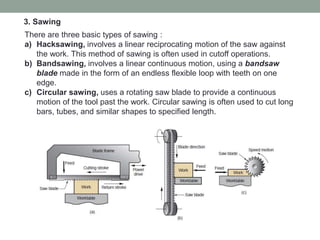

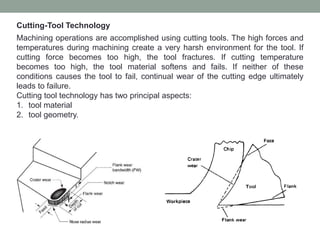

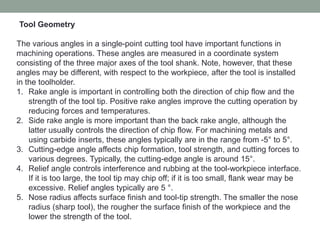

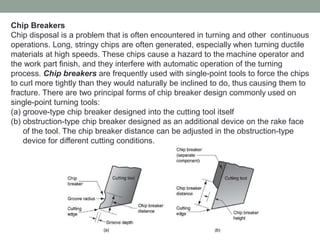

The document provides a comprehensive overview of machining processes, including types like turning, drilling, and milling, along with various operations and techniques associated with each. It details aspects of cutting tool technology, including tool materials, geometry, and properties essential for effective machining. Additionally, it discusses problems related to chip disposal and the use of chip breakers to enhance operational efficiency.