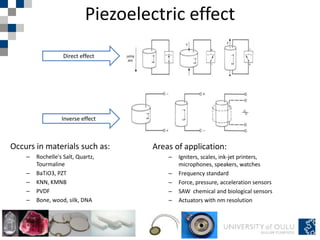

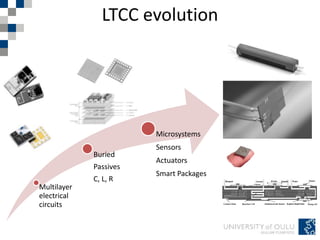

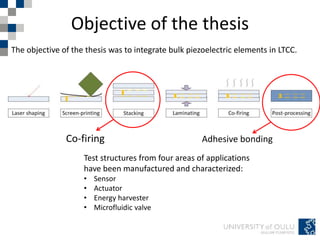

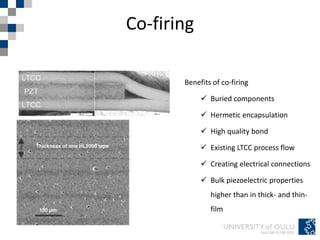

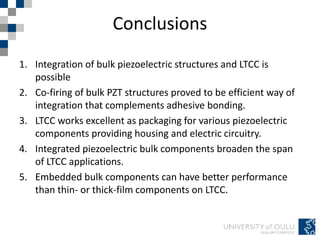

This document discusses embedding bulk piezoelectric structures in Low Temperature Co-fired Ceramic (LTCC). It outlines the piezoelectric effect, describes LTCC and its applications, and presents the objectives of integrating bulk piezoelectric elements in LTCC. Key results are then summarized for four application areas: an optical filter actuator, an energy harvester, an accelerometer sensor, and a microfluidic valve. The conclusions are that co-firing bulk piezoelectric structures is an efficient integration method, LTCC provides excellent packaging for piezoelectric components, and embedded bulk components can outperform thin or thick film ones.