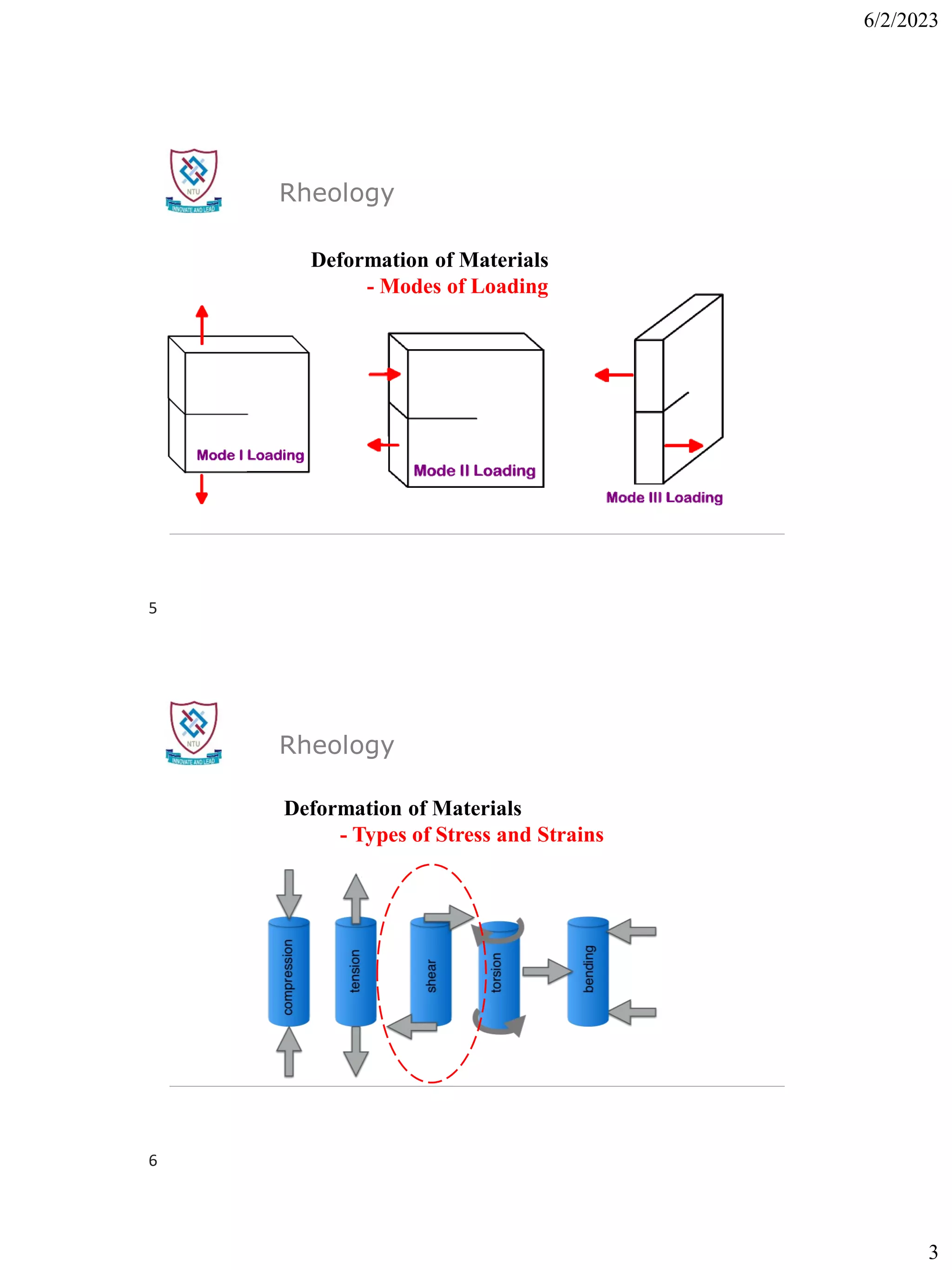

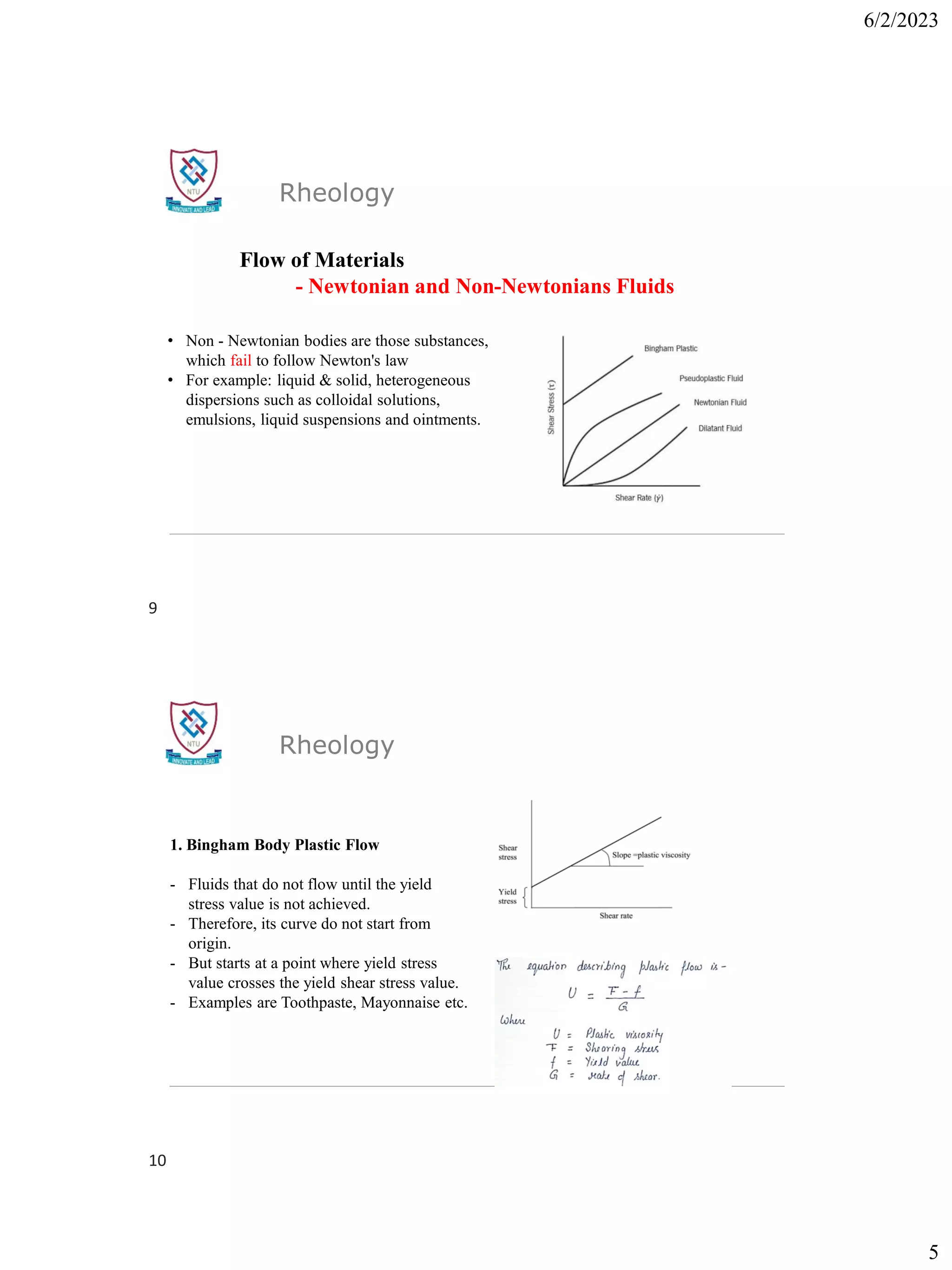

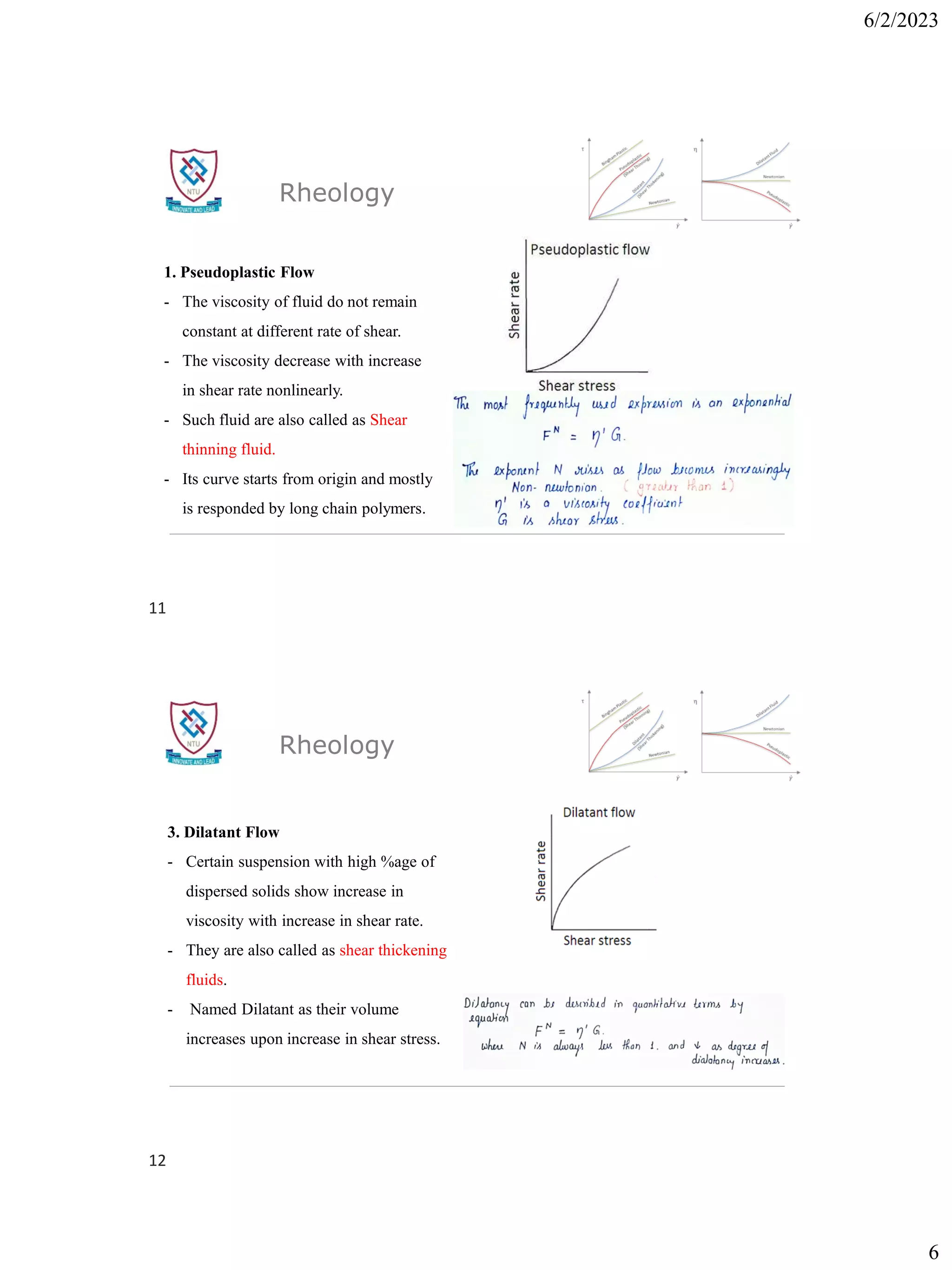

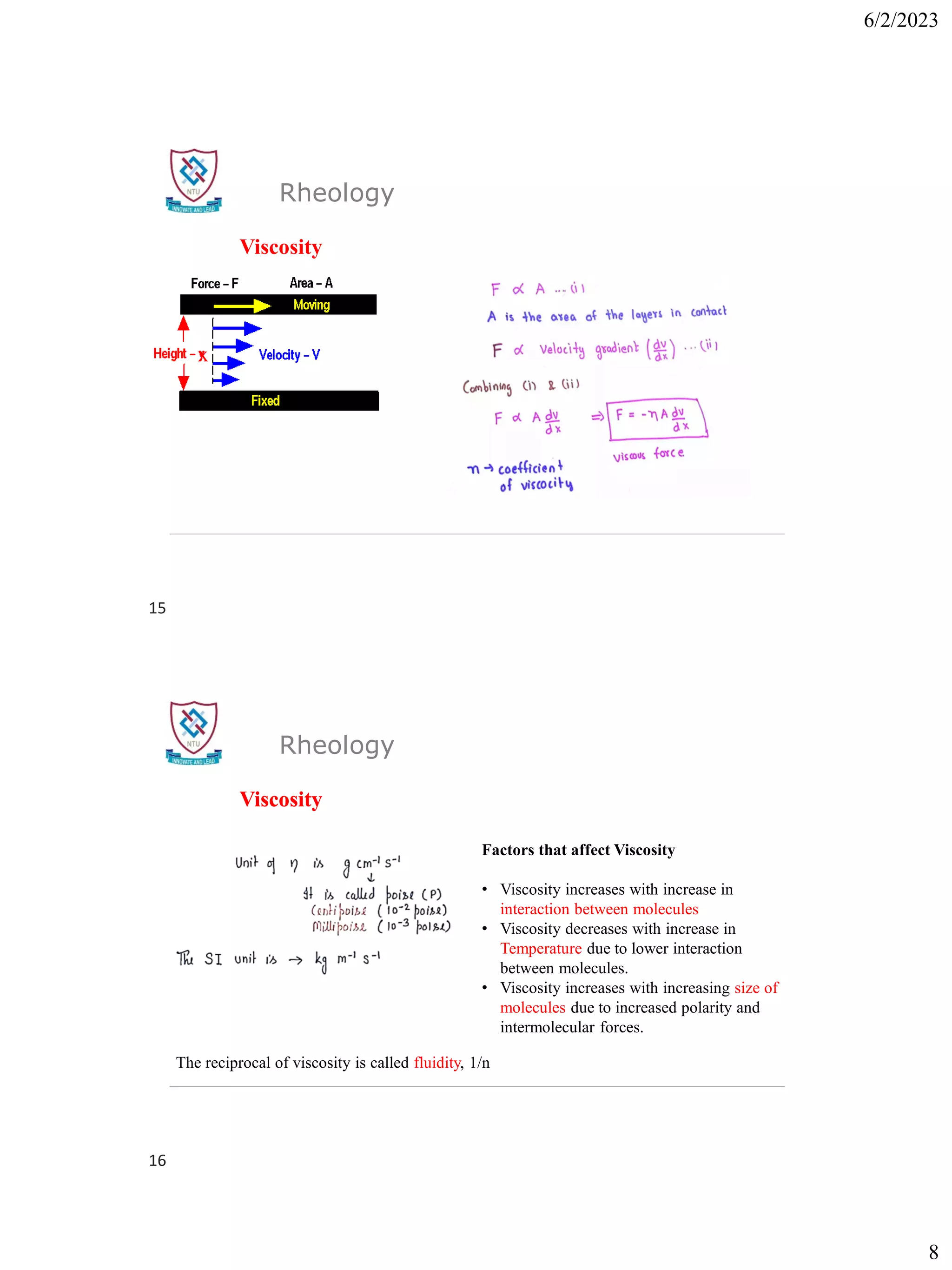

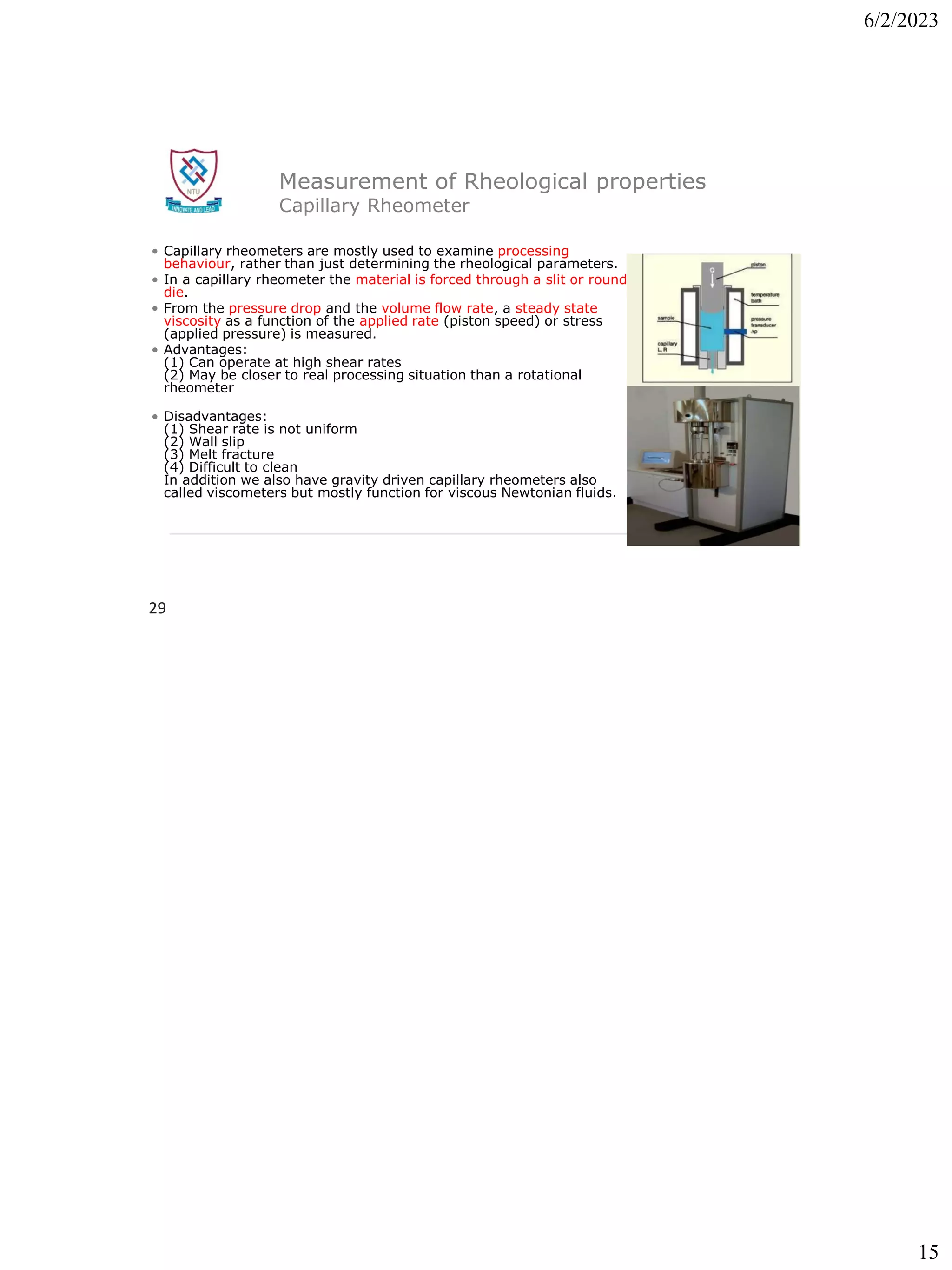

This document discusses rheology and the measurement of rheological properties. It begins with definitions of rheology and deformation of materials under different types of stress and strain. It then discusses Newtonian and non-Newtonian fluids, including examples of different types of non-Newtonian fluid flow. The document also covers viscosity, factors that affect viscosity, and viscoelastic behavior of polymers. Finally, it discusses various methods for measuring rheological properties, including rotational rheometers, capillary rheometers, and melt flow indexers.