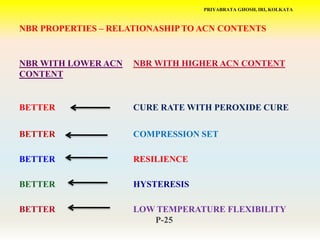

NBR is a copolymer of butadiene and acrylonitrile. It is prepared via emulsion polymerization similarly to SBR. NBR has better oil resistance than SBR and NR due to its nitrile content. It requires more softeners during compounding due to its tough nature. Common fillers, plasticizers, and curatives are used. NBR finds use in oil resistant applications and can be blended with materials like PVC and phenol formaldehyde resins to improve properties. Its vulcanizates exhibit good abrasion resistance and aging properties but low temperature flexibility depends on acrylonitrile content.

![PRIYABRATA GHOSH, IRI, KOLKATA

NITRILE RUBBER (NBR)

• NBR IS A COPOLYMER OF BUTADIENE AND ACRYLONITRILE.

CH2 = CH – CH = CH2 + CH = CH

(BUTADIENE) (ACRYLONITRILE)

CN

RANDOM COPOLYMERISATION

~~[~~CH2 – CH = CH – CH2 – CH2 – CH–CH2 – CH = CH – CH2~~]n~~

CN

P-1](https://image.slidesharecdn.com/nitrilerubber-3-200716062557/85/Nitrile-rubber-3-2-320.jpg)