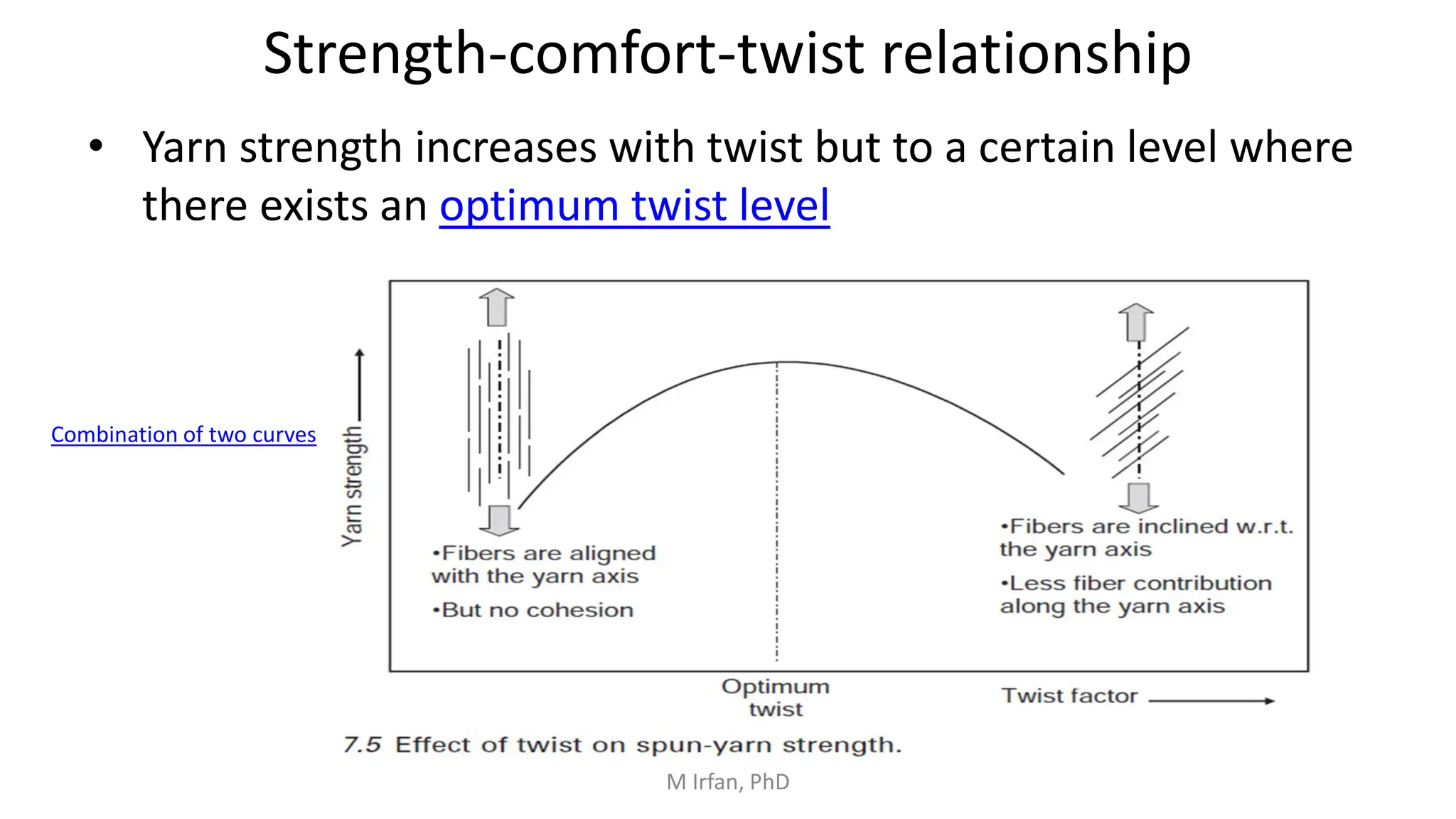

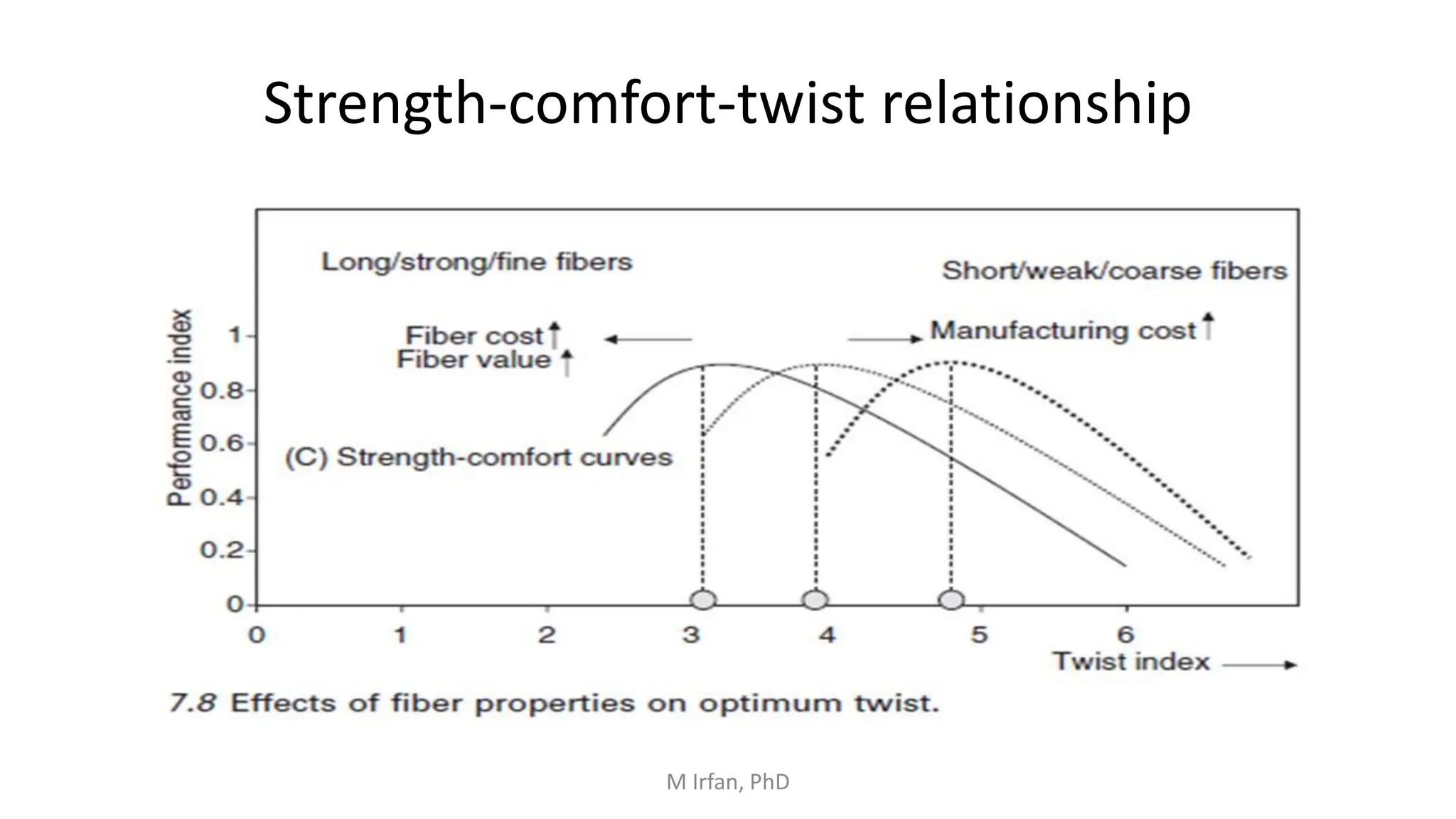

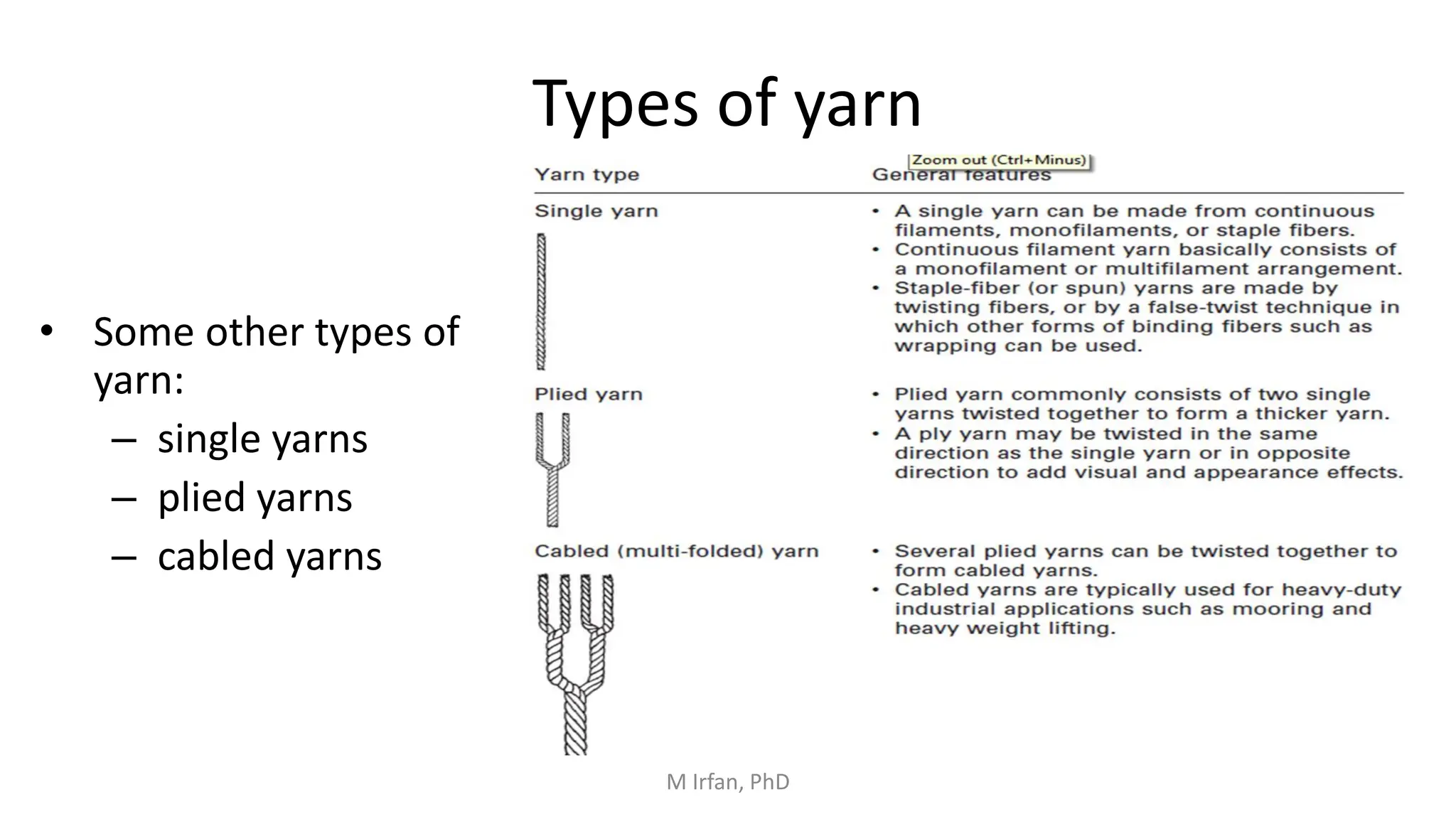

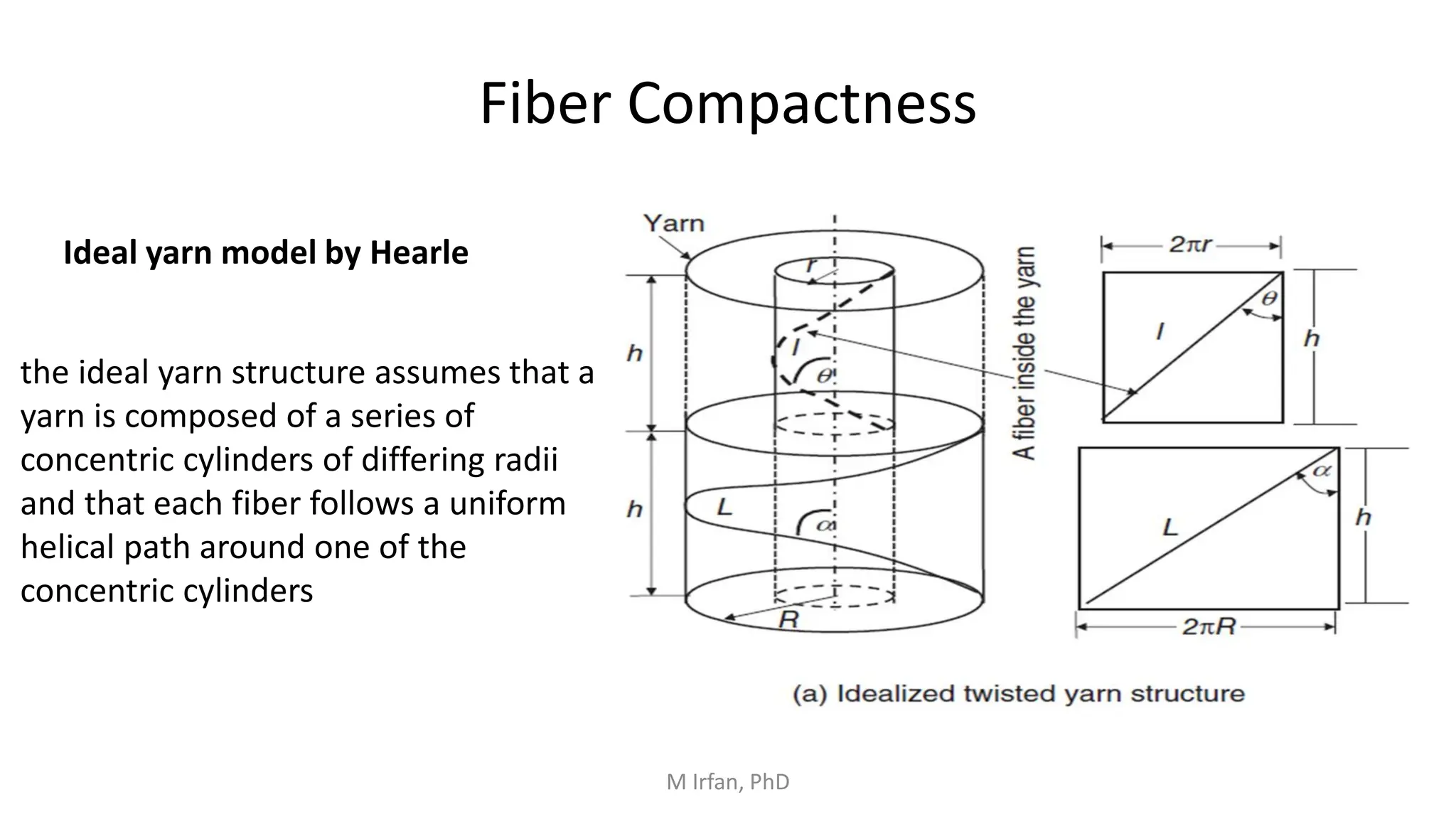

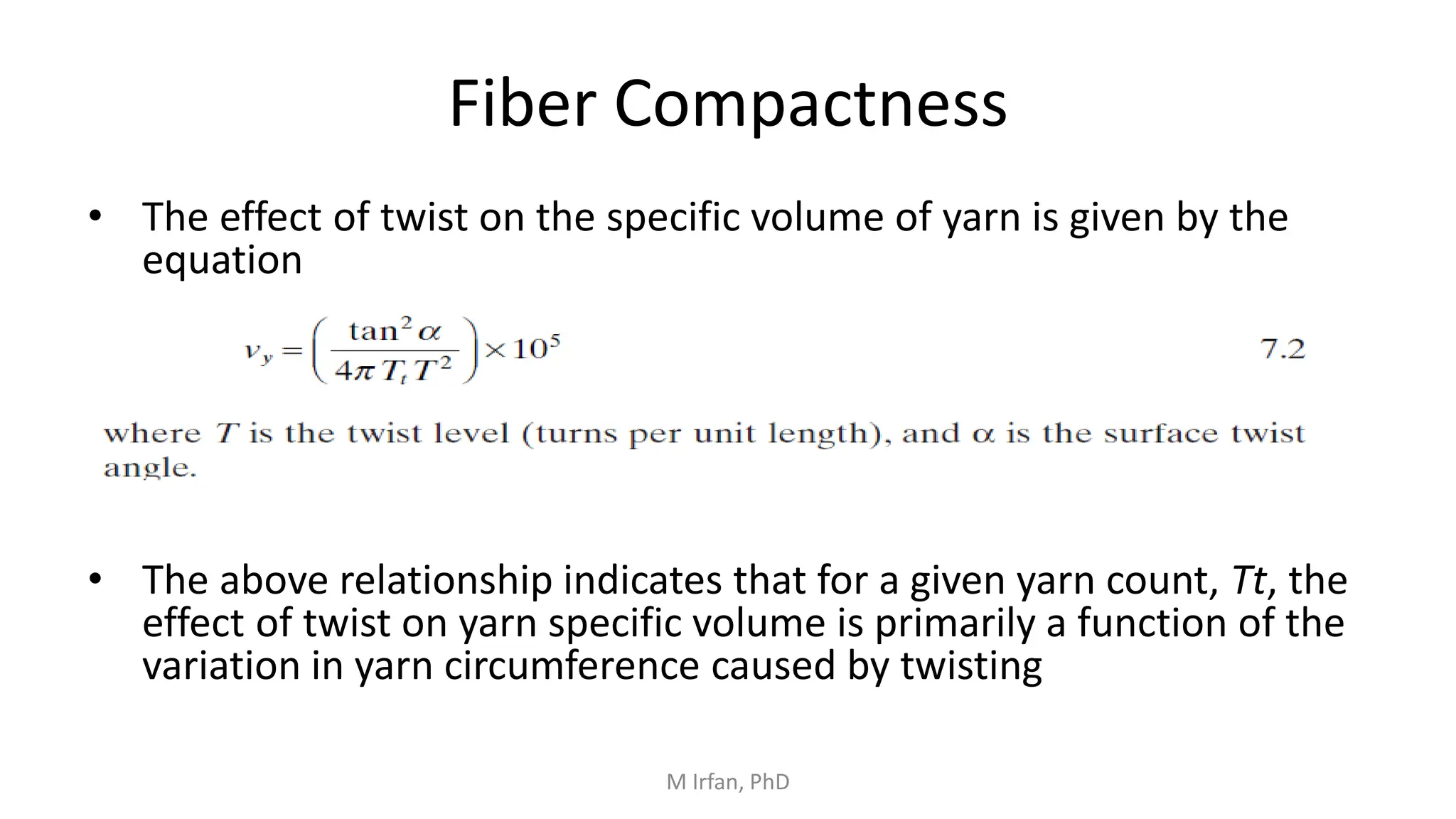

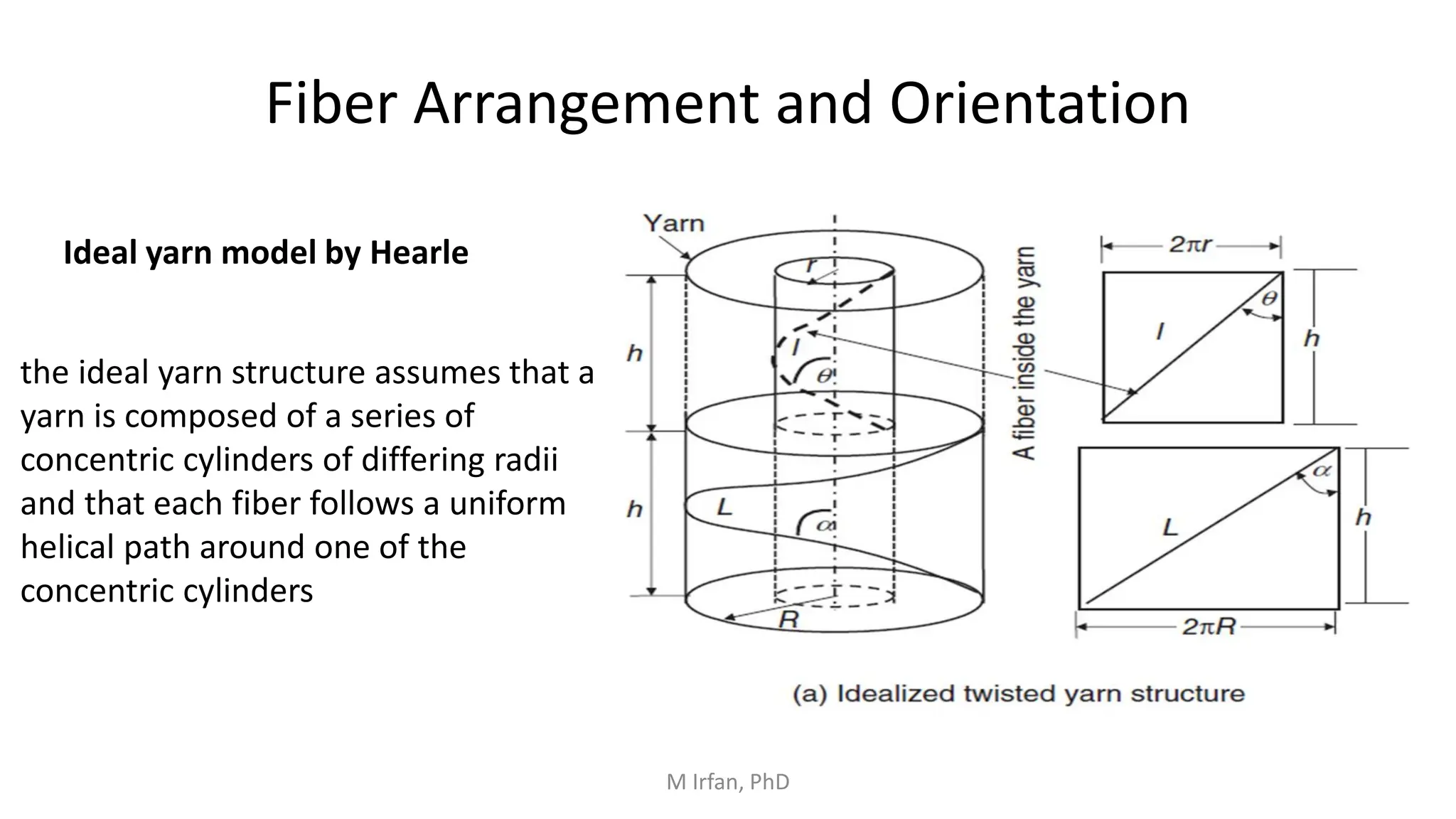

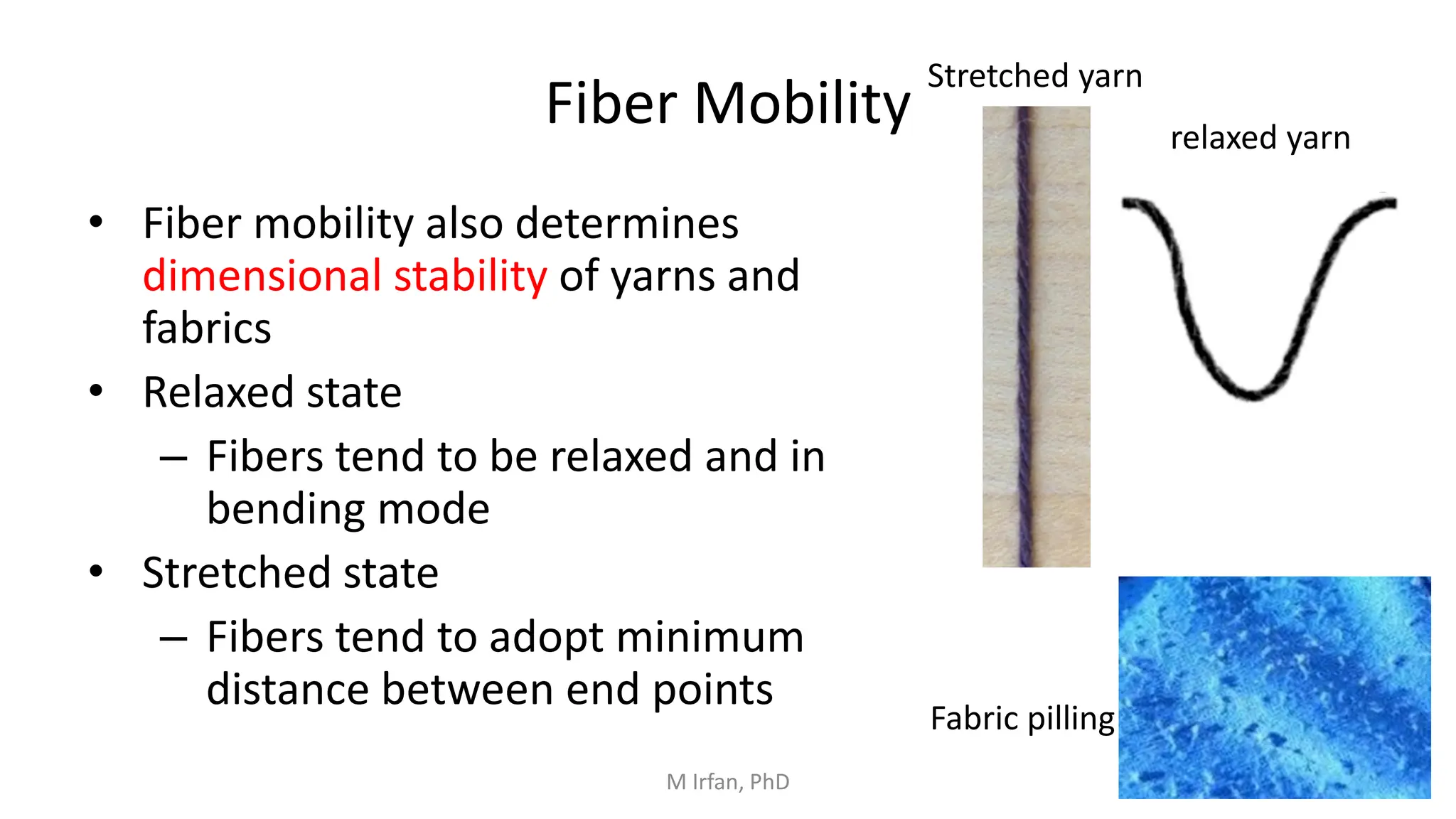

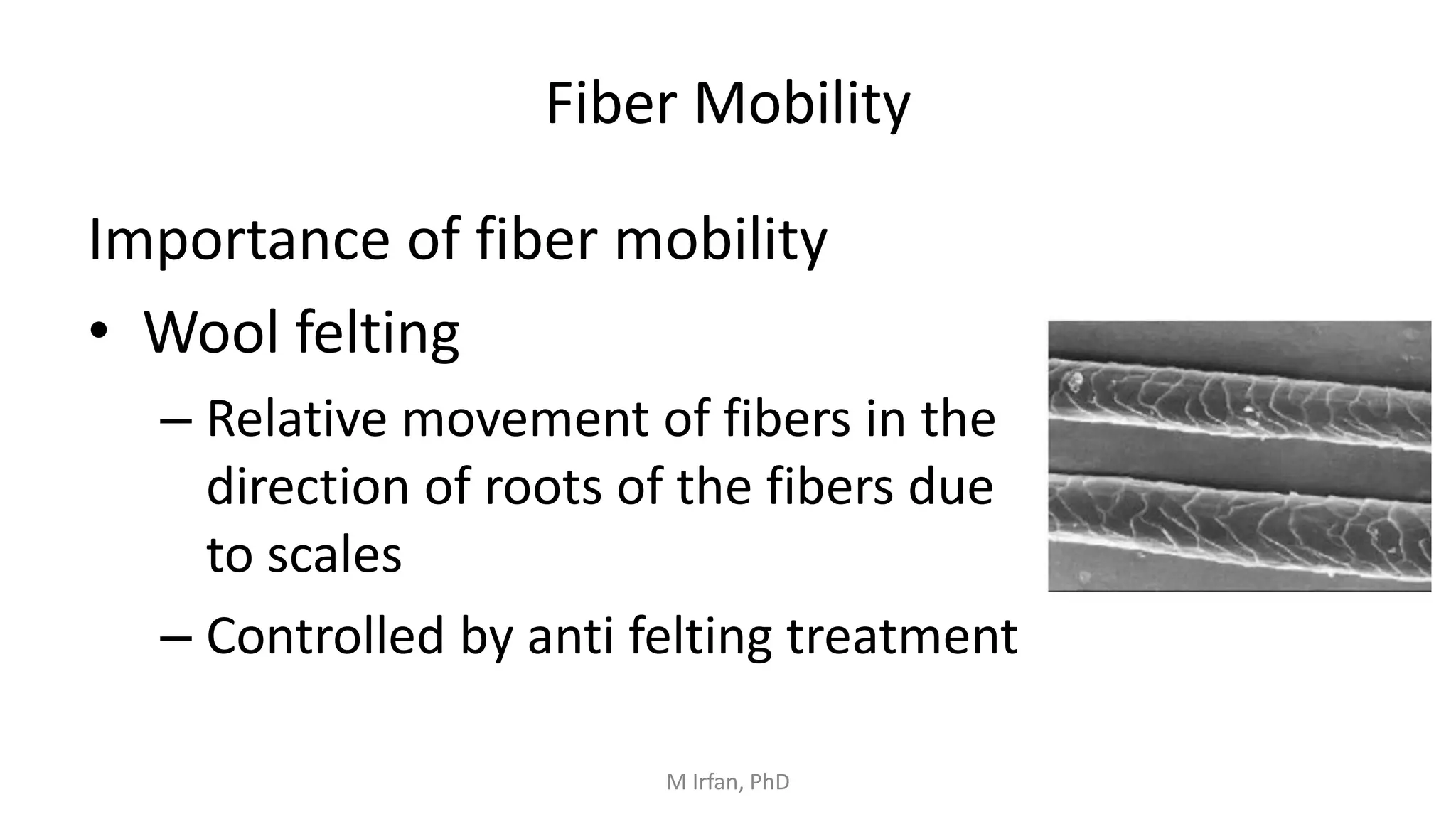

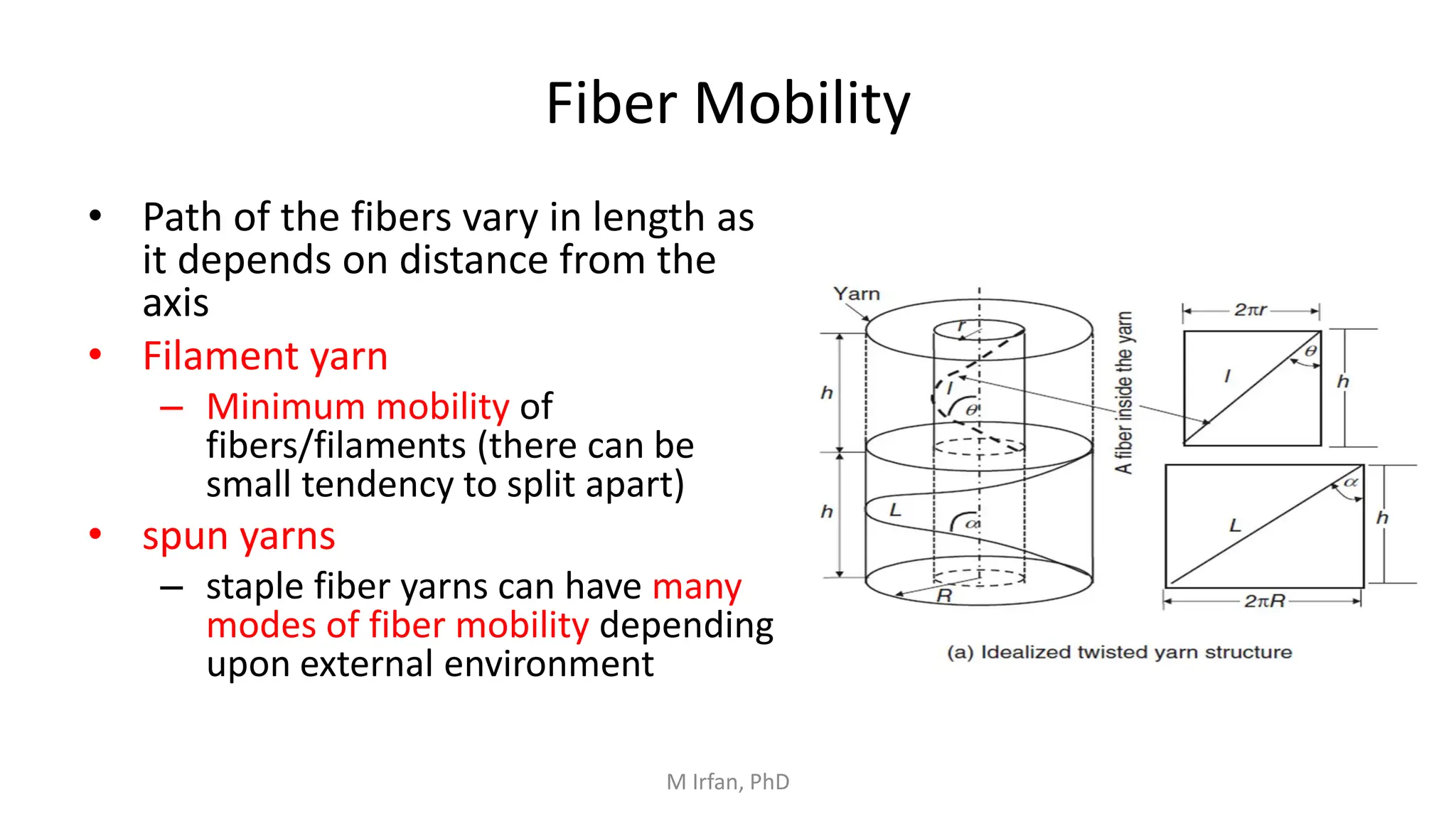

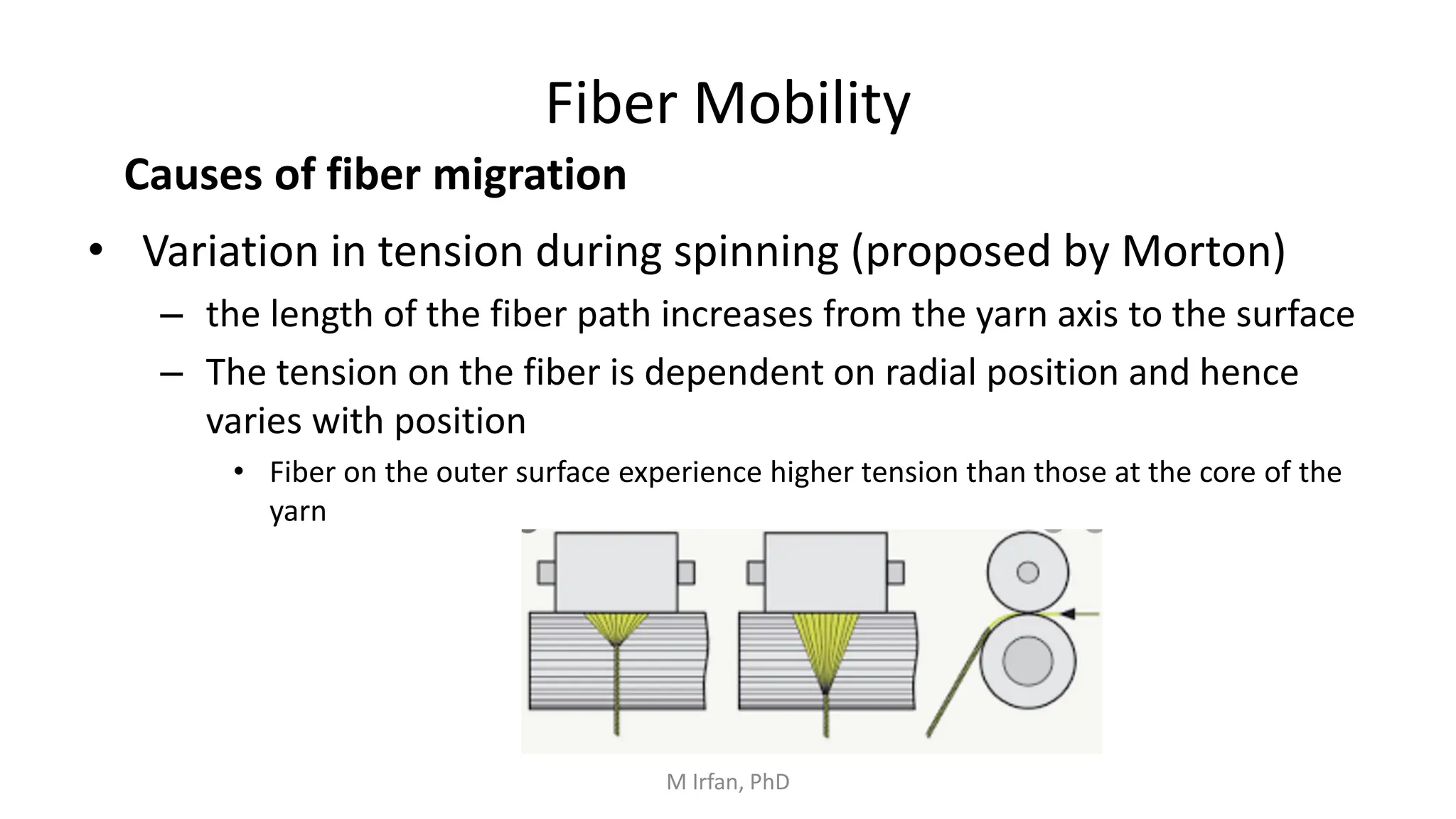

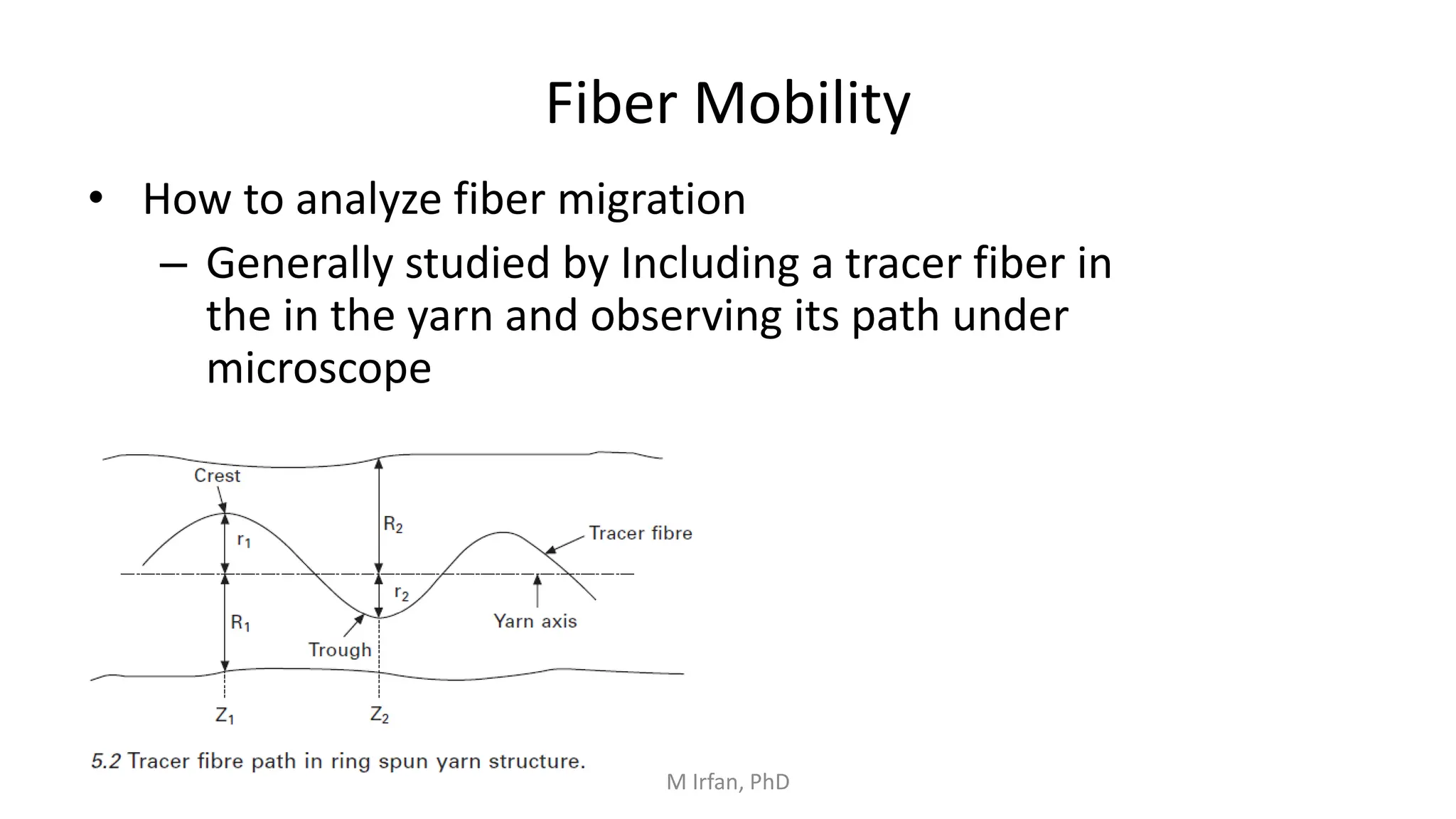

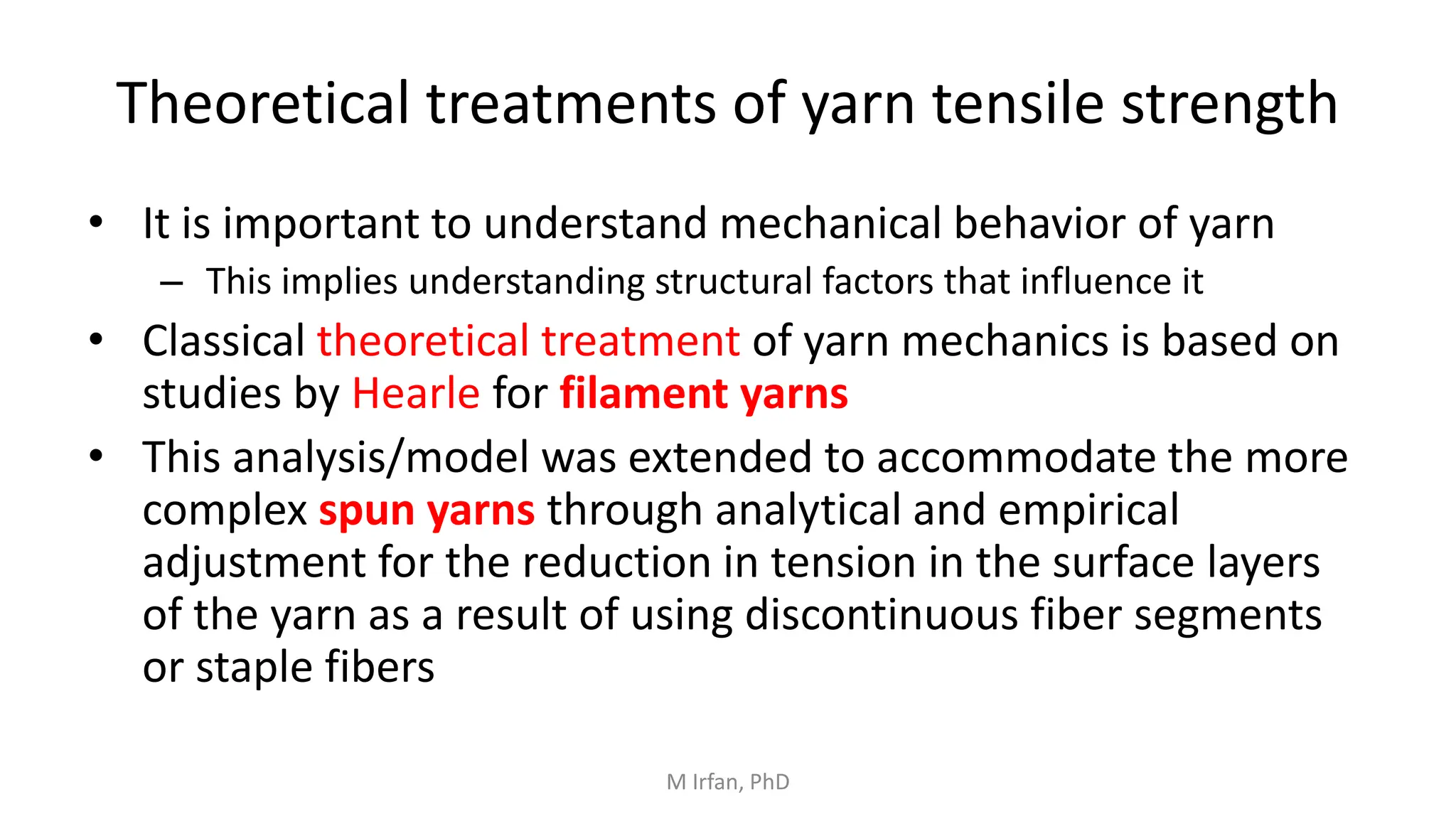

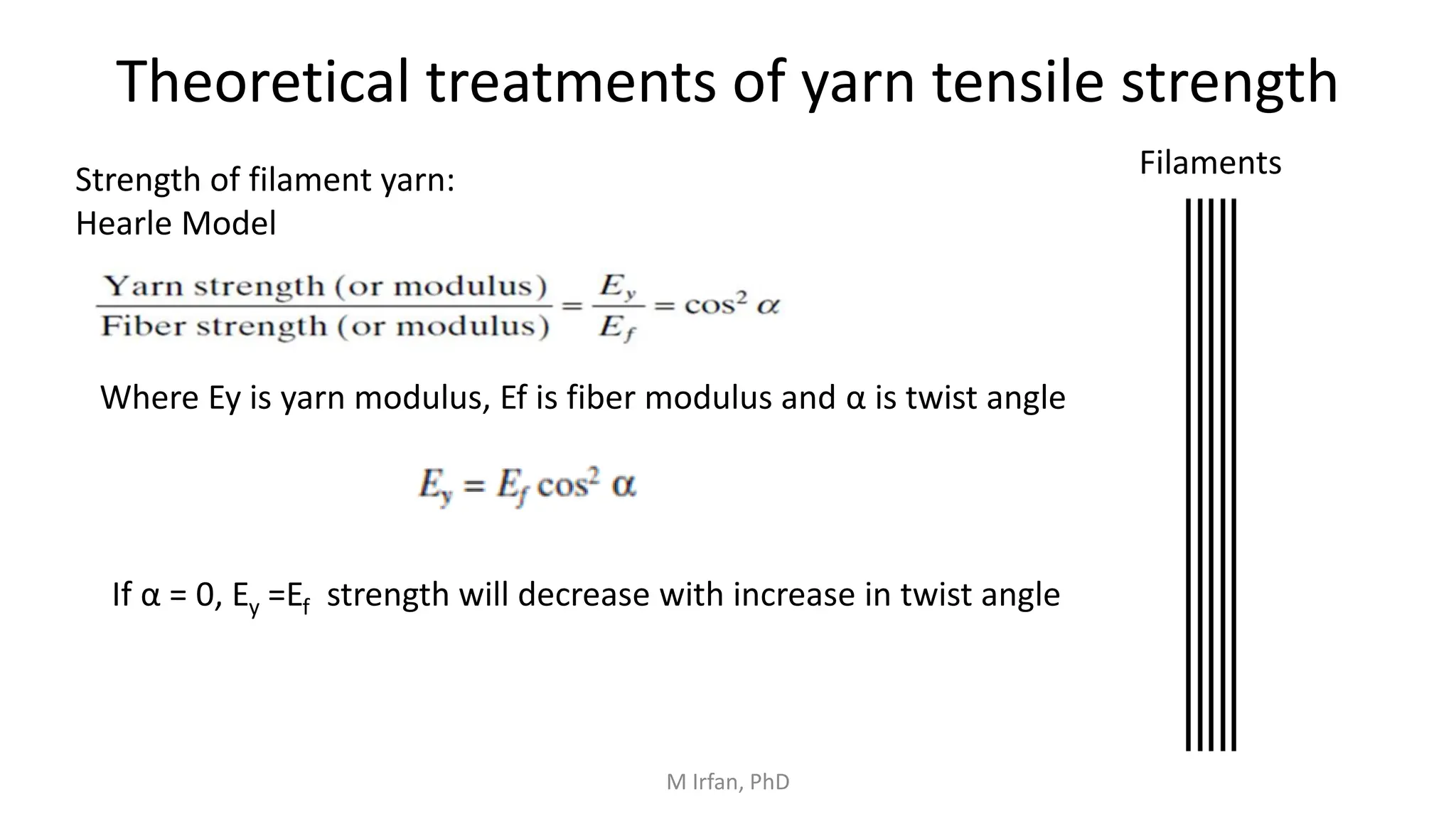

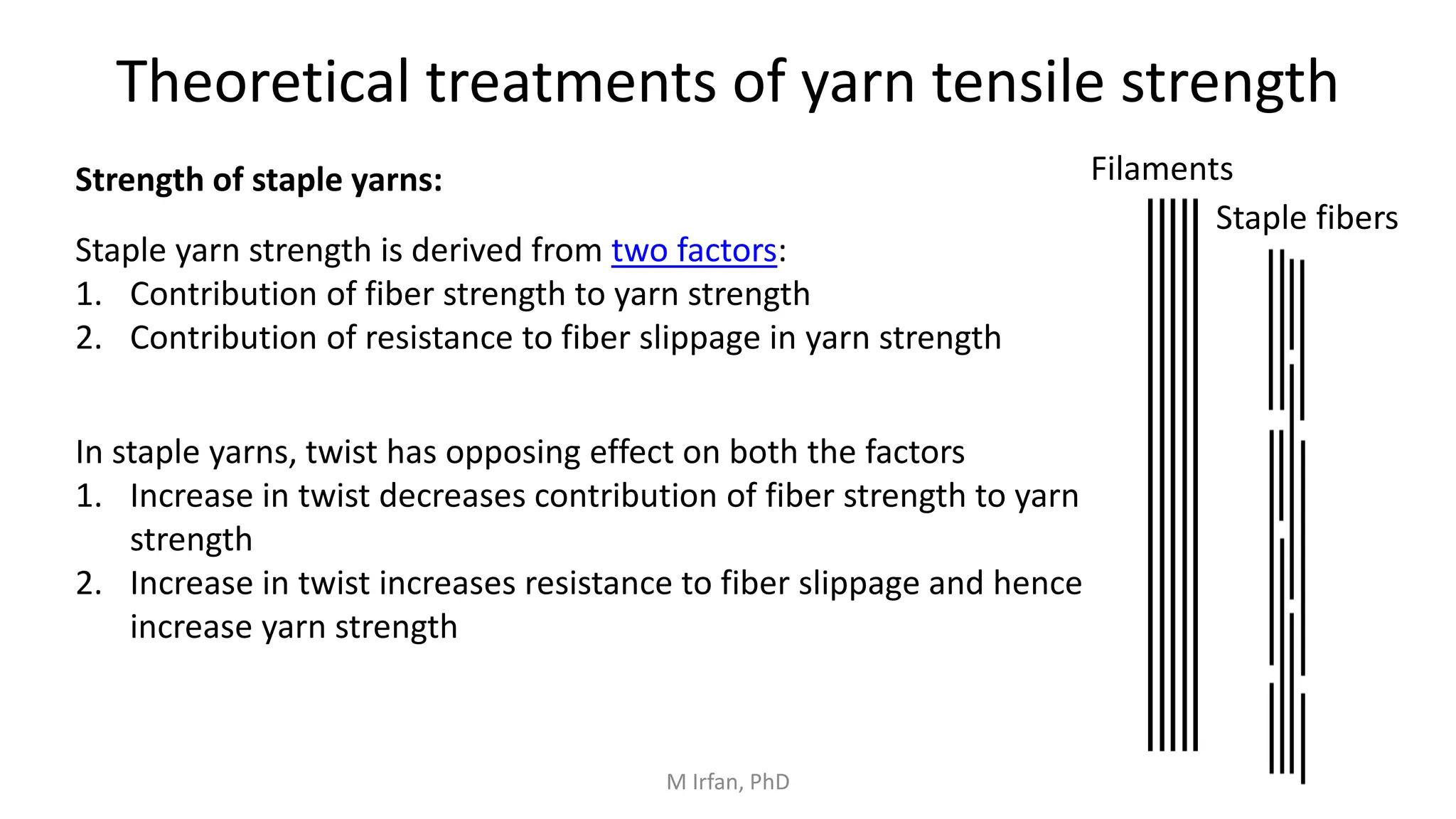

This document provides an overview of mechanics of fibrous structures, specifically focusing on yarn structure. It discusses key aspects of yarn structure including fiber compactness, fiber arrangement, and fiber mobility. Fiber compactness influences yarn properties like strength and hand feel. Fiber arrangement impacts properties like strength and dimensional stability. Fiber mobility within yarns influences pilling resistance and other performance characteristics. The document also discusses different yarn types and theoretical models for predicting yarn tensile strength based on fiber and filament properties.

![Theoretical treatments of yarn tensile strength

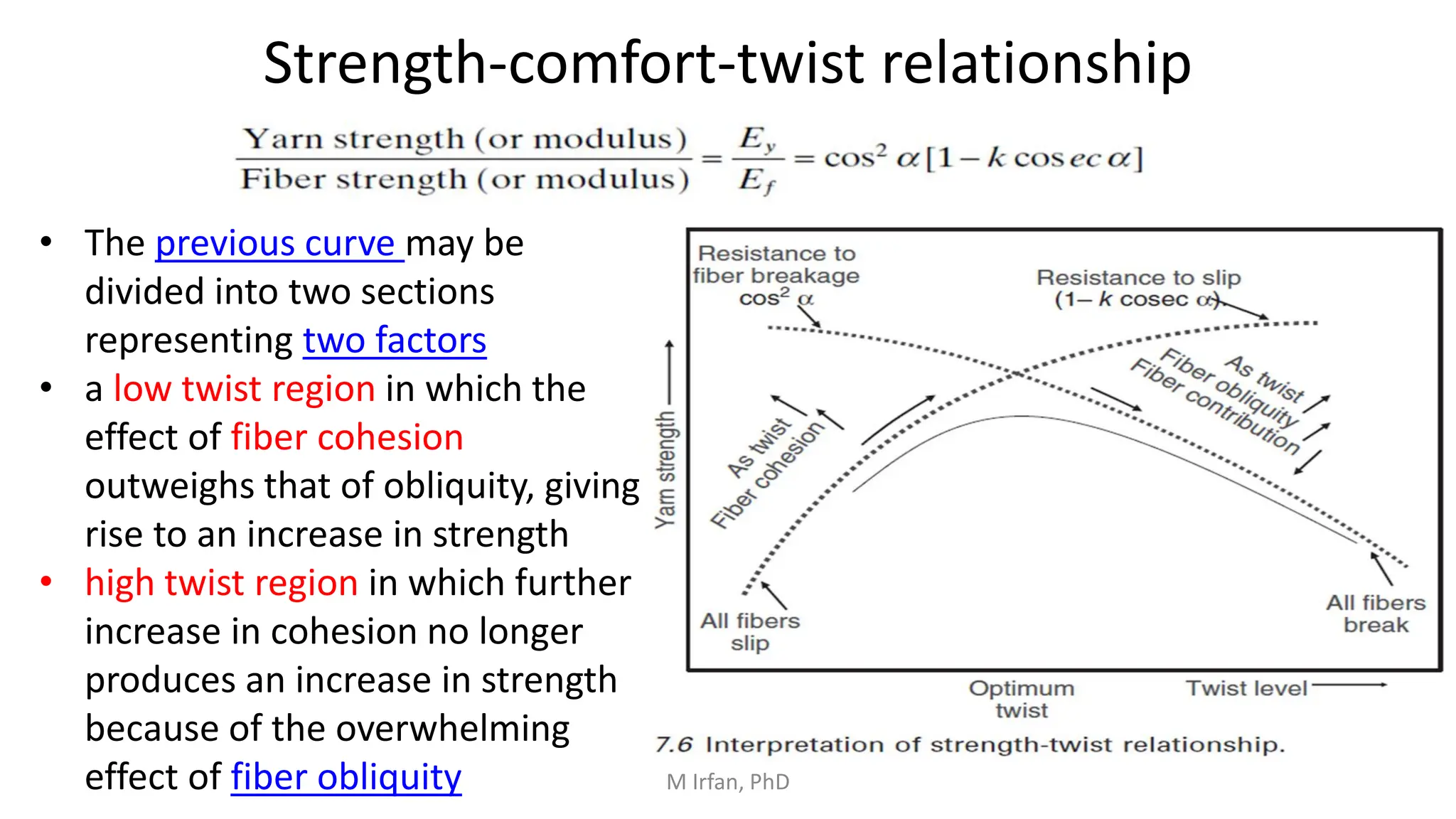

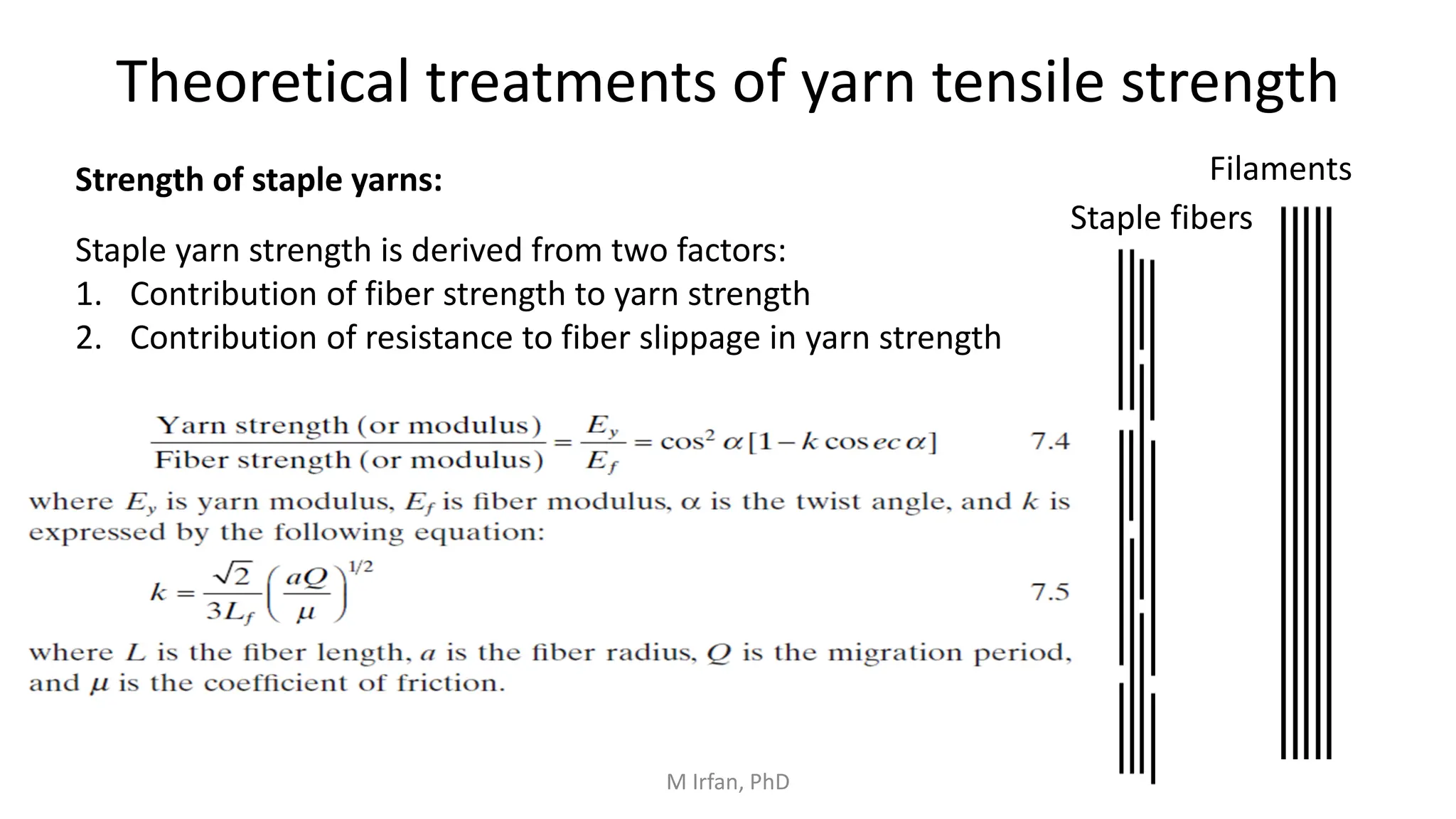

• This equation is called strength-twist relationship

and has two components which contribute to

strength

– Cos2α: decreases strength with increase in twist

– [1-kcosecα]: increases strength with increase in twist

dependent on value of k

M Irfan, PhD](https://image.slidesharecdn.com/te-3113-7-240103062012-b559ede0/75/TE-3113-7-pdf-mechanics-of-fibrous-Structure-slides-45-2048.jpg)

![Theoretical treatments of yarn tensile strength

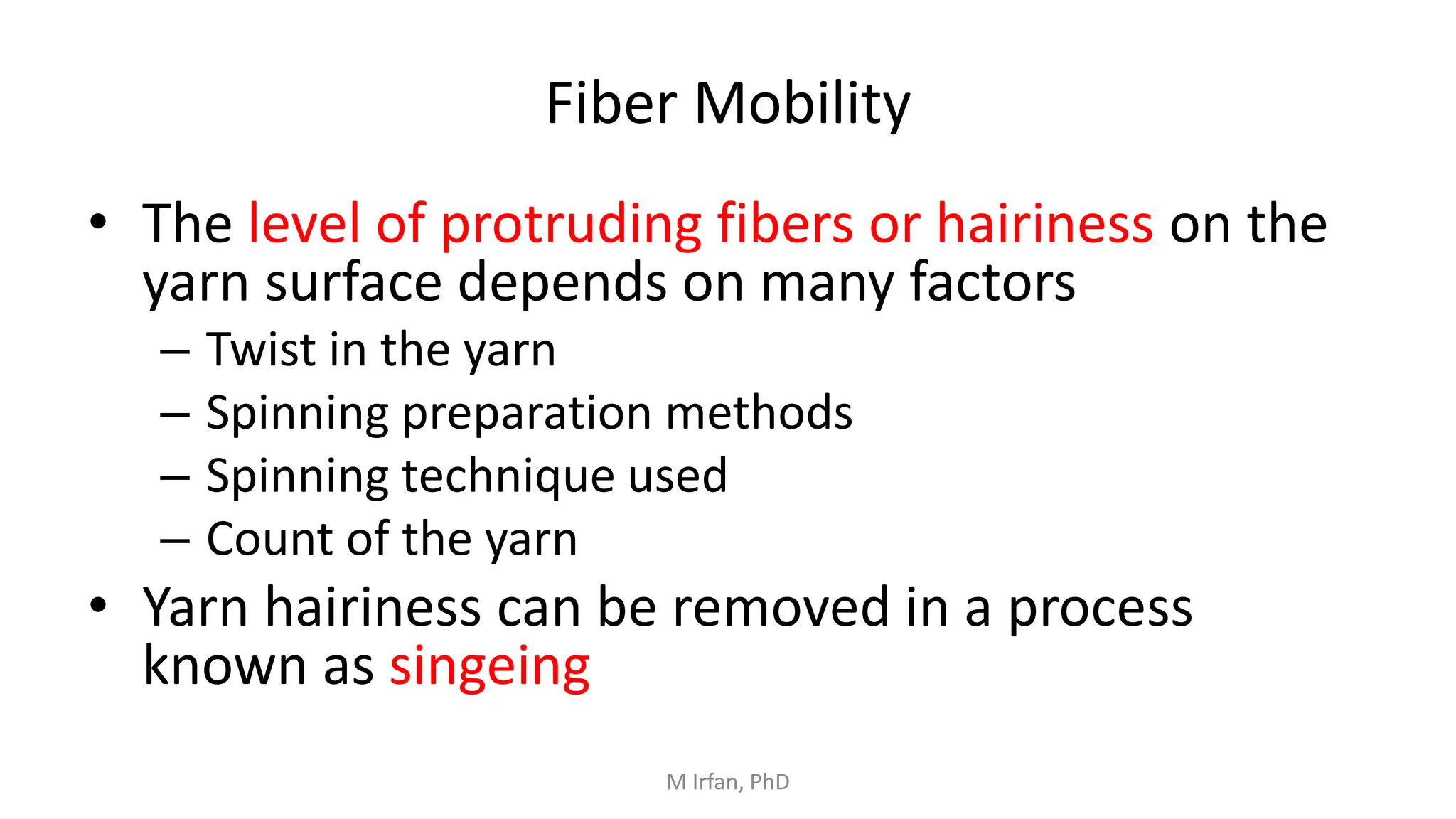

• How “k” contributes to strength

– Increase in fiber length decreases ‘k’ and increases yarn strength

[due to increase in (1-kcosecα)]

– Increase in fiber diameter (a) increases ‘k’ and decreases yarn

strength [due to decrease in (1-kcosecα)]

– Increase in fiber friction (μ) decreases ‘k’ and increases yarn

strength [due to increase in (1-kcosecα)]

– Increase in fiber migration period (Q) increases ‘k’ and decreases

yarn strength [due to decrease in (1-kcosecα)]

M Irfan, PhD](https://image.slidesharecdn.com/te-3113-7-240103062012-b559ede0/75/TE-3113-7-pdf-mechanics-of-fibrous-Structure-slides-46-2048.jpg)