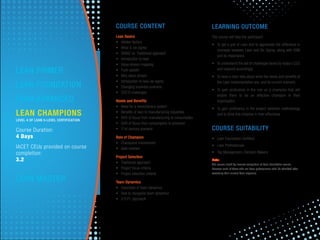

The document outlines the principles and methodologies of lean management, emphasizing waste elimination for value creation in customer-oriented processes. It describes an educational program consisting of a 5-level certification framework developed by SSA, which includes various courses designed to enhance participants' understanding and application of lean practices across industries. Additionally, the document highlights SSA's expertise, CEU accreditation, and customized training solutions aimed at fostering continuous improvement in organizations.