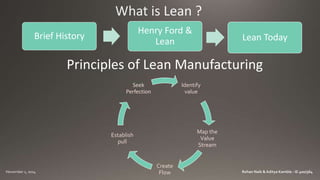

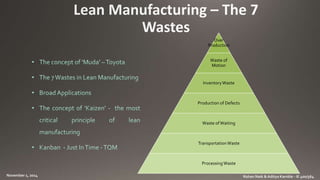

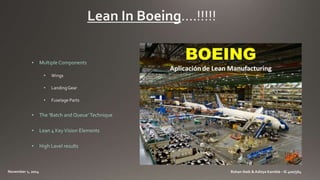

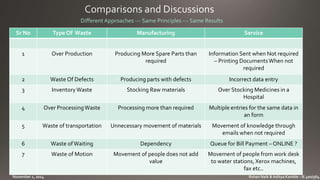

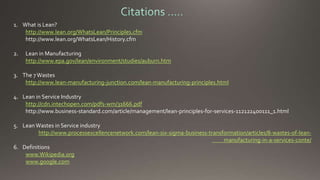

The document discusses lean manufacturing principles and their application in both manufacturing and service industries, highlighting the seven types of waste: overproduction, defects, inventory, over-processing, transportation, waiting, and motion. It contrasts lean practices in companies like Boeing and Motorola while emphasizing the importance of efficiency, quality improvement, and cost reduction. Additionally, it suggests that lean can be applied broadly as a business strategy to enhance profitability.