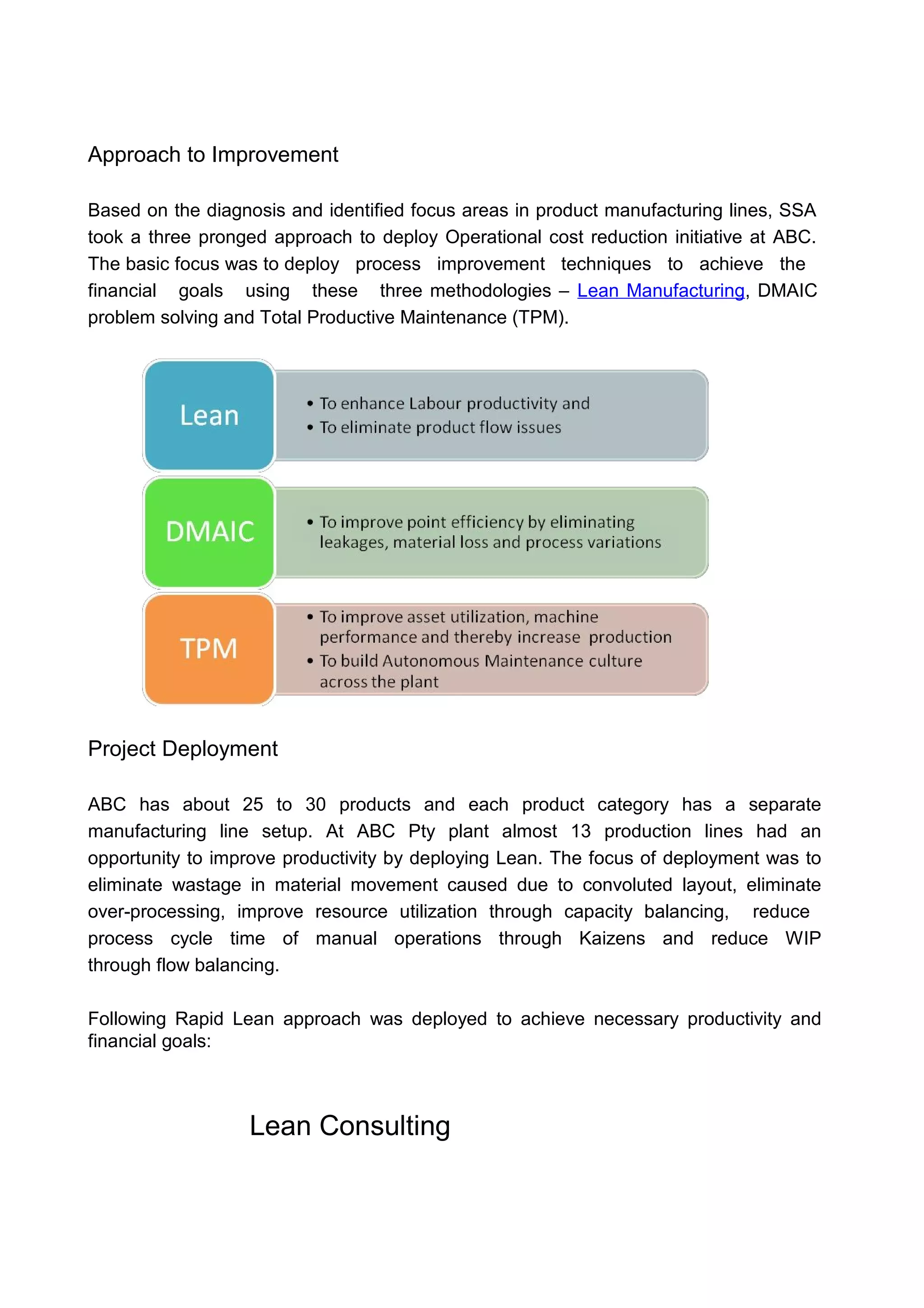

SSA partnered with ABC Pty, an Indonesian FMCG subsidiary of an Indian company, to improve profitability. ABC was facing rising costs from increased minimum wages and a devalued local currency. SSA conducted a diagnosis across ABC's operations to identify profit leaks and opportunities for process optimization. They then deployed a three-pronged approach using Lean Manufacturing, DMAIC problem solving, and Total Productive Maintenance techniques to reduce costs through eliminating waste, improving resource utilization, reducing cycle times, and decreasing work-in-process. The goal was to help ABC compensate for increased costs through operational cost reductions.