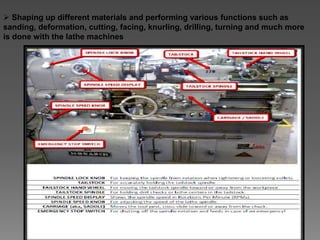

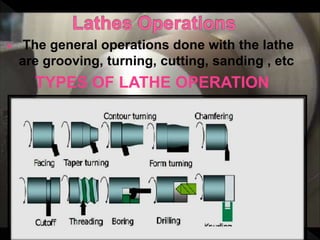

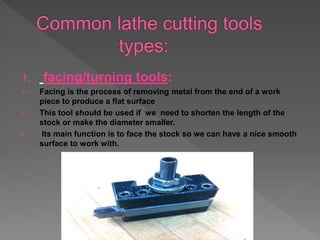

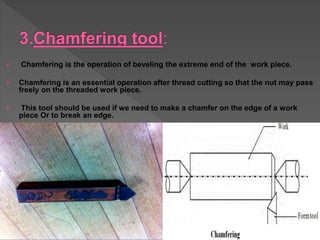

Lathe is a machine that helps shape materials into desired forms by performing operations like turning, cutting, sanding, knurling and drilling. Common lathe operations include facing, turning, grooving and parting. Facing removes metal from the end of a workpiece to create a flat surface. Chamfering bevels the edge of a workpiece, such as after thread cutting. Knurling imprints a diamond pattern onto a surface for better grip. Parting cuts a groove through a workpiece to shorten it.