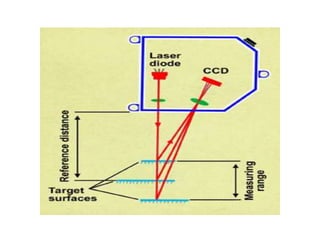

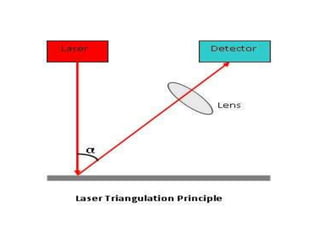

Laser triangulation sensors use a laser diode to project a light spot onto a target surface. The reflection is focused onto a light detector, and the position of the reflected spot indicates the target's position. There are two main types of receivers - position sensitive devices and charge coupled devices. Position sensitive devices have been used for longer but are sensitive to surface conditions, while charge coupled devices can now react faster with new technology. Laser triangulation sensors offer non-contact measurement with high accuracy, but the laser beam can be a hazard and measurements cannot be made very close to the sensor. They are used for applications like ride height measurement, displacement measurement, and thickness measurement.