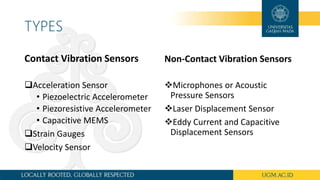

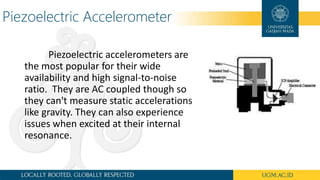

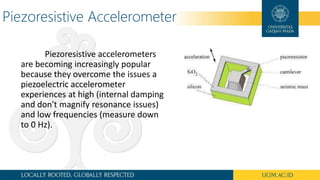

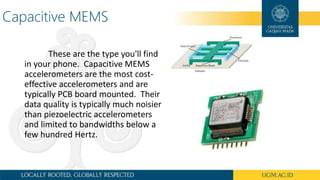

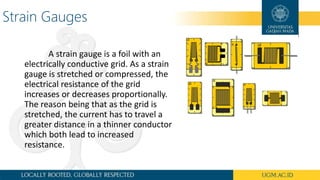

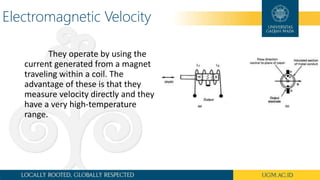

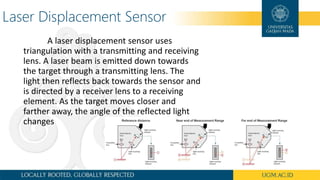

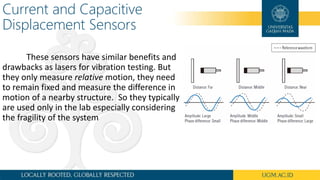

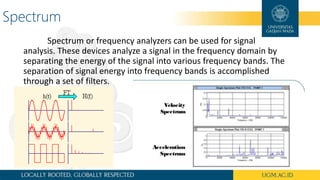

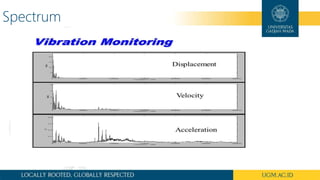

Vibration sensors detect vibrations and convert them into electrical signals. There are two main types: contact sensors that must mount directly to the object, and non-contact sensors that measure vibrations without direct contact. Common contact sensors include piezoelectric accelerometers, piezoresistive accelerometers, and strain gauges. Common non-contact sensors include microphones, laser displacement sensors, and eddy current sensors. Vibration data can be analyzed in both the time and frequency domains to diagnose machine problems.