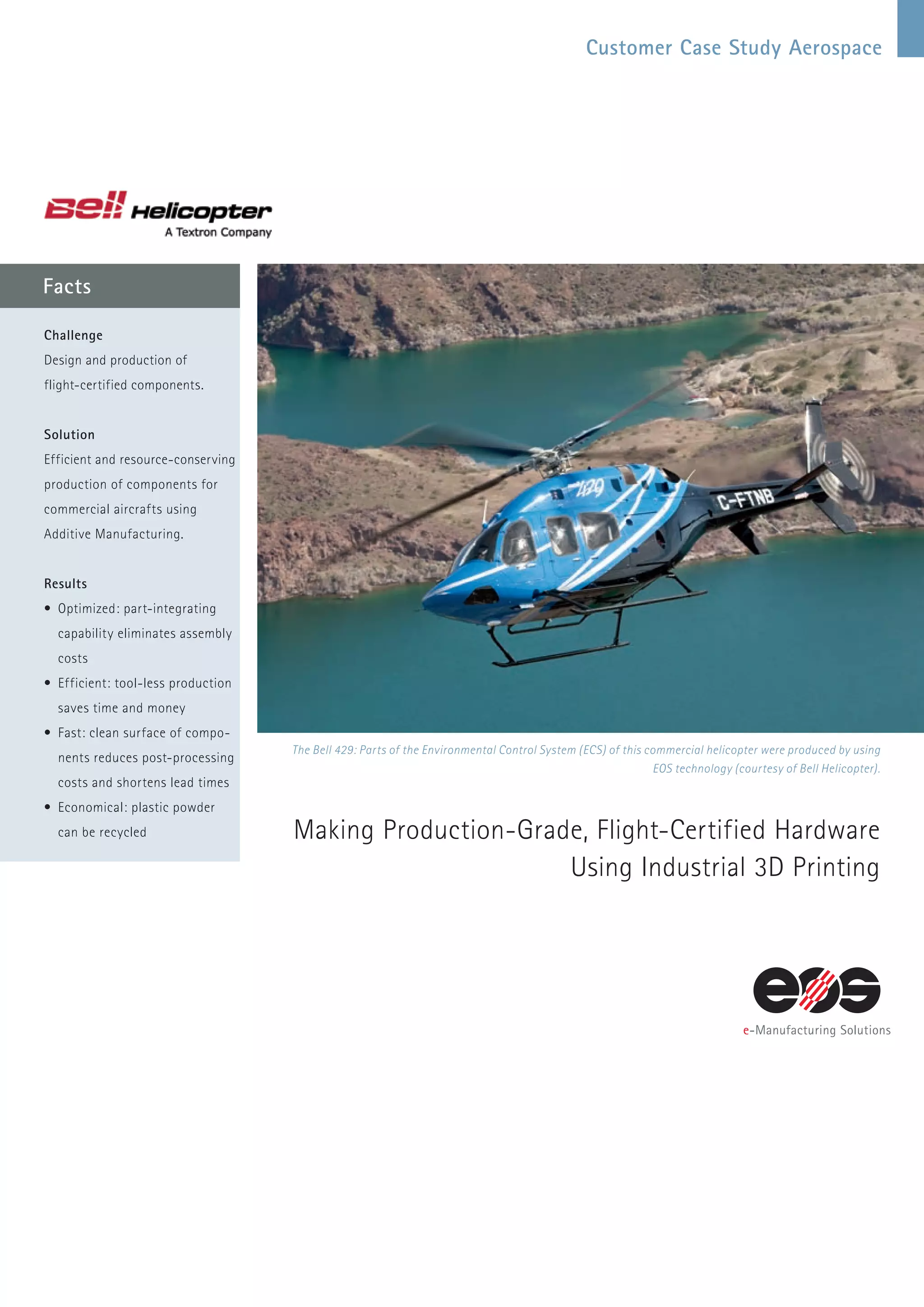

Bell Helicopter partnered with Harvest Technologies to produce parts for the environmental control system of the Bell 429 helicopter using EOS technology, focusing on efficient and resource-conserving additive manufacturing. The collaboration improves production by eliminating assembly costs, reducing lead times, and increasing recyclability of materials. As a result, Bell Helicopter is expanding the use of additive manufacturing throughout their aircraft systems, benefiting from significant design and manufacturing advantages.