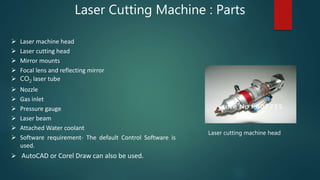

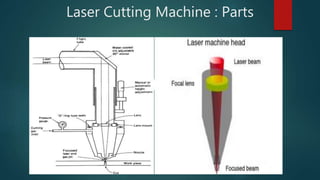

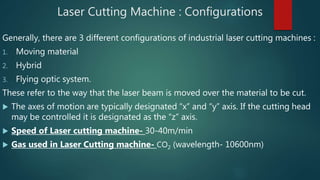

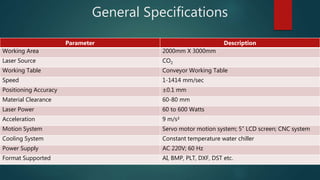

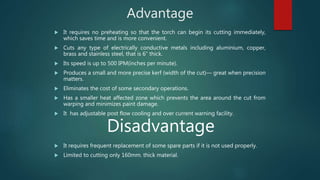

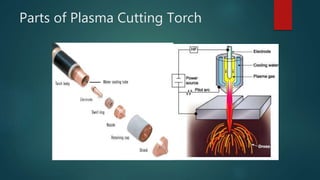

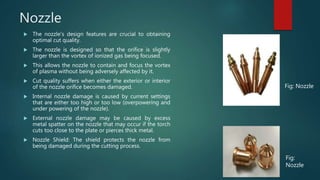

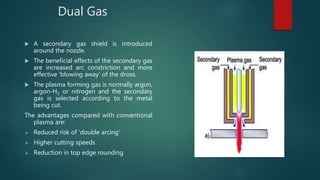

This document provides information about laser cutting and plasma cutting machines. It discusses the basic working principles of lasers and how laser cutting machines function. It describes the key components of laser cutting machines like the laser source, optics, nozzle, and CNC system. It also discusses factors that influence cut quality and different configurations of laser cutting machines. The document then provides details about plasma cutting, including the plasma state, common gases used, and how plasma cutting torches work. It lists the advantages of plasma cutting over other techniques and describes process variants to improve cut quality.