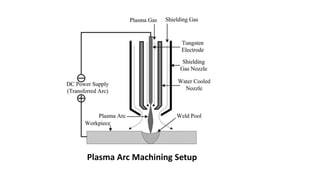

Plasma arc machining uses ionized gas at extremely high temperatures (11,000 to 30,000°C) to remove material from a workpiece. A plasma torch generates the ionized gas plasma from gases like hydrogen, nitrogen, or argon. The high-velocity plasma jet melts and blows away the molten metal from the workpiece. Plasma arc machining can cut hard metals and leaves a narrow kerf but has high equipment and operating costs.