Knitting project

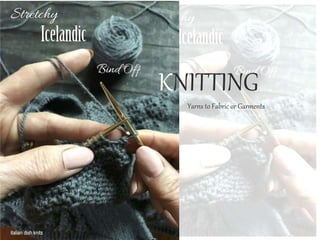

- 1. KNITTING Yarns to Fabric or Garments

- 2. A Project On KNITTING PROJECT Submitted To Dezyne E’cole College, Civil Line, www.dezyneecole.com By Monika Samtani B.Sc Fashion Technology 2 Year

- 3. Dezyne E’cole College 106/10 Civil Lines Ajmer-305001, Raj Tel. 0145-2624679 www.dezyneecole.com This project report of Mrs. Monika Samtani student of B.Sc. In Fashion Technology 2nd Year, has been checked and has been graded as Thanking you Principal (seal & signature)

- 4. ACKNOWLEDGEMENT I 'am Monika Samtani, student of Fashion Design department of Design E’cole College. I would like to show my gratitude to the mentors who had helped me to make this project successfully and for the encouragement for this project. I also thank Dezyne E’cole College for giving me this opportunity to make this technical project and looking for my insight capability.

- 5. Classification of Knitted Fabrics Weft Warp Plain-Knit Stitch Purl Stitch Rib Stitch Tricot Knit Simplex Knit Raschel Knit Ketten Raschel Knit Crochet Knit Weft-insertion Warp Knit Other types of Knitting Jacquard Knitting Pile Knitting Fleece Knitting High Pile Knitting Terry Knitting Velour Knitting Milanese Knit

- 6. WEFT KNIT Process- The plain-knit is the basic form of knitting. It can be produced in flat-knit or tubular form. The knitting is done with a row of latch or beard needles arranged in a linear position on a needle plate or in circular position on a cylinder. All the needle. All the needles are evenly spaced side by side and are moved by cams, which act on the needle butts.

- 7. PLAIN-KNIT STITCH FRONT BACK Process- The plain-knit is the basic form of knitting. It can be produced in flat-knit or tubular form. The knitting is done with a row of latch or beard needles arranged in a linear position on a needle plate or in circular position on a cylinder. All the needle. All the needles are evenly spaced side by side and are moved by cams, which act on the needle butts. Properties- The plain knit produces a relatively lightweight fabric compared with the thicker fabrics produced by other stitches. It is high rate of production is an expensive, and lends itself readily to variation in design by pattern devices. These variations include stripes, multicolored patterns, textured surfaces produced by raised designs, pile effects.

- 8. PURL STITCH Process-This construction is also referred to as the links-and-links stitch. It is made on flat-bed and circular machines by needles using hooks on both ends to alternatively draw loops to the front of the fabric in one course and to the back in the next course. it is a slower and more costly technique. The purl knit will run up and down if a loop is broken. But a purl knit fabric will not curl at the edges. The use of double-hook needles enables ready changeover during fabric construction to include flat and rib stitches, which makes its possible to duplicate virtually may hand-knitted structure. It lends itself to the heavy, jumbo stitch that produce the familiar bulky effect. Because the purl stitch has crosswise stretch and excellent lengthwise stretch, it is widely used in infants and children’s wear.

- 9. RIB STITCH Process-Rib knit fabrics have alternating lengthwise rows of plain and purl stitches constructed so that the face and back of the fabric appear alike. This may be produced either on a flat rib machine or circular rib machine.. In the flat rib machine, one set of needles is placed opposite the other set of needles is an inverted V position of 45 degree to the horizontal; in the circular rib machine, one set of needles is placed vertically in a cylinder and the other set of needles is place horizontally on a dial. the rib stitch has excellent widthwise elasticity. This characteristic has resulted In its extensive use in apparel where snugs of fits is essential.it is also used for underwear and socks for men and children.

- 10. WARP KNITTING Warp knitting differs from weft knitting, basically in that each needle loops its own thread. The needles produce parallel rows of loops simultaneously that are in interlocked in a zigzag pattern. the stitches on the face of the fabric appear vertically, but at a slight angle; and the stitches on the back appear horizontally as floats at a slight angle. These floats called laps, or underlaps, are a distinguishing identification of warp knits. Warp knitting may be flat or tubular and can be produced in many varieties of patterns. The seven types of warp knitting are tricot, Milanese, simplex, reschel, ketten reschel, crochet, and weft-insertion warp.

- 11. TRICOT KNITTING The word tricot comes from French word tricoter, which means knit. The machine has one or more warp beams mounted above it. Each set of yarns from a warp beam is fed to a row of needles arranged across the width of the machine and is controlled by yarn guide set in the guide bar that is also laid across the machine. Since one guide bar is used for each set of warp yarns, the number of guide bars employed. Tricot fabrics have many good attributes. They are porous. They also offer bulk without undue weight. Tricot fabrics are soft, wrinkle resistant, have good drapability. They

- 12. RESCHEL KNITTING The reschel knit ranks in importance of production with tricot, but it surpasses it in variety of products, which range from veiling and laces to powernets for foundation garments such pile fabrics as carpets. The reschel knit made with latched needles rather than the bearded type used for tricot, Milanese, and simplex.

- 13. KETTEN RESCHEL KNITTING The knit is also called the chain raschel. It is a variation of the tricot knit that produces a course gauge of 14 to 20 needles per inch on width of 90 to 120 inches. The machine can be equipped to produce raised pattern effects in one or more colors by a shell stitch construction. Since the kitten raschel knit is produced with bearded needles, the fabric is finer, has a better hand, superior elasticity, and cover.

- 14. CROCHETS The basic stitch is used in hand-crochet work employing a pillar chain. Using either latch or beard needles, this construction is used in wide variety of fabrics ranging from nets and laces to bedspreads and carpets.

- 15. MILANESE KNIT Milanese stitch, though accomplished a fabric very similar in appearance to tricot. It can be identified by the fine rib on the face and a diagonal patterns pattern on the back. Milanese is knitted on the flat bed machine with spring-beard needles and on the circular machine with latch needles. It is usually knitted from filament yarn into fine lightweight fabrics. Milanese fabrics are superior to tricot in smoothness, elasticity, regularity of structure, and split and tear resistances

- 16. Simplex knit Milanese stitch, though accomplished a fabric very similar in appearance to tricot. It can be identified by the fine rib on the face and a diagonal patterns pattern on the back. Milanese is knitted on the flat bed machine with spring-beard needles and on the circular machine with latch needles. It is usually knitted from filament yarn into fine lightweight fabrics. Milanese fabrics are superior to tricot in smoothness, elasticity, regularity of structure, and split and tear resistances

- 17. JACQUARD KNITTING Both weft and warp knitting can incorporate the jacquard mechanism to produce multicolored designs. The jacquard punched-card technique used in weaving can also be adapted to knitting. Cards control the selection or inhibition of the needles to produce the pattern. Jacquard knits are made on flat-bed and circular machines, and the fabric may be flat or ribbed. The fabrics are multicolored, each color requires consecutively its own respective feed on each course of the design. The back of the fabric can be varied, as with a noel effect, striped, pique, blister, or solid back.

- 18. PILE KNITTING The production of pile knits has steadily grown in variety, importance, and volume. They are constructed as fleece, high pile terry , and velour knits. Depending upon the type of construction, they are used for fur fabrics, rugs, and fashion apparel fabrics.

- 19. Fleece knit The production of pile knits has steadily grown in variety, importance, and volume. They are constructed as fleece, high pile terry , and velour knits. Depending upon the type of construction, they are used for fur fabrics, rugs, and fashion apparel fabrics.

- 20. High pile knit The production of pile knits has steadily grown in variety, importance, and volume. They are constructed as fleece, high pile terry , and velour knits. Depending upon the type of construction, they are used for fur fabrics, rugs, and fashion apparel fabrics.

- 21. TERRY KNITTING Knitted terry fabrics are made of a variation of the jersey knit construction where two yarns are fed simultaneously into the same needles. The fabric is knitted by a plaiting technique which causes one yarn always on the back of the cloth. As the fabric is knitted, the face yarn is pulled out by small devices to form the loop pile, leaving the other yarn to serve as the ground. Knitted terry is produced in weights ranging in suitability for robes and beachwear to fashion apparel. VELOUR KNITTING Knitted velour fabrics are constructed in the same manner as knitted terry. After the material is knitted, the loop pile is sheared at a uniform height and then brushed. This produces a soft, suedelike surface that is somewhat like that of velvet. However, knitted velour is softer and has better drapability. It is used for such fashion apparel as men’s shirts and women’s dresses.

- 22. TWO DIVISIONS OF THE KNITTING INDUSTRY Knitted industry has two main divisions:- • One divisions produces knitted goods for apparel manufacturers, for sewing, centers, for consumers and for others. • Other divisions produces completed apparel like hosiery, sweaters and underwear.

- 23. FULLY CUT KNITTED GARMENTS A knitted garment where all edges are cut from a length of knitted fabrics. Fully cut and stitch type such as T-Shirts, Lady’s Tops, Shorts, Skirts.

- 24. FULLY FASHIONED KNITTED GARMENTS This is the way knitwear was always produced with each component to the correct size and shape and then the components sewn together. The machinery to produce components to the correct shape are much longer, so most commercially available knitwear is not produced this way. In this the shaping of the garments done on the machine or knitting needles, so that all selvedges are finished. Fully-fashioned knitting cuts down on the amount of material required to make a garment by eliminating selvage, the remnants that would be left after cutting from a rectangular fabric sheet. For example, a sweater requires at least four pieces of fabric, two sleeves, the front piece, and the back piece. Prior to fully fashioned machine techniques, a full sheet of material would have to be produced, each of the four pieces would cut out, and the remaining fabric would be discarded. With full-fashioning the machine produces only the four required pieces. The necessary techniques for changing the fabric width or diameter are achieved by:- • Changing knit structure. • Varying the structural elements • Shaping through loop transfer • Wale fashioning by “needle parking”. • Segmented takedown for varying rates of takedown across the width of the fabric.

- 25. FULLY FASHIONED SHAPED KNIT GARMENTS Shaped knitwear is engineered to size and shaped at the point of knitting, it is very distinctive and easily identifiable by the “fashioning marks” which normally run parallel to the garment seems. The welts and cuffs are knitted as an integral part of the panel, leaving only the collar to be added during garment make-up. The garment panels are assembled using “cup seaming” and “linking” where usually the garment sides, sleeves and underarms are cup seamed and the shoulders and collars are linked. The difference between linking and seaming is that with linking a stitch per stitch joint results whereas cup seaming stitches the edges of the fabrics together.

- 26. CUT AND SEW KNIT GARMENTS The cut and sew techniques is by far the simplest method of garment construction whereby individual panel shapes are cut to size from panels or from a long length of fabric or cloth. The benefits of the cut and sew route include, ease and speed of knitting fabric total consistency of cut panel sizes relatives ease of garment make-up. The downside is that the seams have to over-looked prior to sewing or linking to prevent the exposed stitches from laddering. This produces a seam that is relatively large, bulky and unsightly. The cut and sew route is not widely used for wool knitwear production, the material wastage and perceived “lower quality” image makes it less appealing.

- 27. COMPLETE KNITTING GARMENTS The garments are essentially the same as normal fully fashioned, expect there is no real seams holding the garment together. The “complete garment” is made by knitting the front panel, the back and sleeves simultaneously as three fabric tubes on the machine, 1 large tube in the middle and 2 smaller ones at either side. These “tubes” are made up of a continuous spiral of yarn that been formed into stitches and each of them is being knit at the same time with a separate cone of yarn. These tubular panels are shaped just like any other piece f fully fashioned knitwear and eventually all 3 panels become “one” to create the finished product. All welts, cuffs and collars are knit at the same time and hence the garment comes off the knitting machine almost ready to wear.

- 28. INNTEGRAL KNITTED GARMENTS Integral knitting means that trimmings, pockets, buttonholes and other accessories are directly knitted in the fully fashion produced panels. With this technique there are fewer post knit processes such as cutting and sewing. Compared with cut and sew and fully fashion production methods, savings can be had in both cutting and sewing post-knit processes. In addition the quality and outlook of the ready garment can be improved by this method of integrating accessories in the panels directly in the knitting process. Also, this production method reduces the cut-loss to a minimum.

- 29. CUT STITCHED SHAPED KNITTED GARMENTS Over the last 20 years there has been a dramatic technical development of machines and software in the production of the knitted fashion garments. This development has made it possible to rationalize design and production of knitted garments so that today it is possible to make a knitted garment, almost readymade, directly in the knitting machine, with a minimum of processes, such as cutting and sewing.

- 30. MACHINES There are number of different machines that can produce shaped knit products. Some of the machines totally eliminate the cut and sew process to produce a seamless garment. Other machine minimize the cut and sew processes to produce a garment with fewer seams than a traditionally made garment. Machines can be divided into three categories. Some machines produce shaped panels such as the front and back bodice and sleeves. After knitting the shaped panel are sewn together to produce a garment. Other garment details such as collars and pockets are added during the sewing processes. Whole garment knitting machines have unique design capabilities. Although there are conventional circular knitting machines that have some of the design capabilities of whole garment machines, they are complicated to program and very expensive. One unique feature of a whole garment knitting machine in individual stitches within a course can be controlled, allowing for increased design capabilities.

- 31. SHIMA SEIKI Since the introduction of whole garment technology in 1995, Shima Seiki has made continuous improvements to the machine design. Researches have concentrated on increasing design capabilities, improving fabric quality, and increasing productivity. In order to create shape, loops are transferred. For latch needles to be able to complete the transfer process on a flat bed machine, a transfer spring is needed. When a transfer spring is present, needles cannot be located in the center of the needle groove. The slide needle uses flexible two-piece slider mechanism instead of a conventional transfer clip. During knitting the mechanism transfer clip. During knitting the mechanism extends beyond the needle hook to aid in the stitch transfer process. In the absence of the transfer clip, the side needle is reduced- distributing can be mounted in the center of the needle groove to produce perfectly symmetrical loops.

- 32. STOLL Stoll manufacturers flat bed knitting machine with the capabilities of knitting seamless whole garments. Stoll refers to their machines as “Knit and Wear”. Stoll machines can knit up to 32 colours, come in range of gauges and have knitting widths ranging from 72 to 84 inches. Stoll’s CAD system is known to be one of the most straightforward systems available. Two computer screens are utilized during the garment development process . One screen displays the technical information, while the other screen displays a representation of the fabric design.

- 33. SANTONI Santoni and Sangiacomo, both owned by Lonati, have the capabilities of producing shaped tubes. Santoni machines are more prevalent than sangiacomo machines in the market place. Santoni has recently deigned two new machines, one with advanced design capabilities and other with the capability of producing shape via a reciprocating motion.

- 34. FLAT BED KNITTING MACHINE A flat bed knitting machine is described, the needle bed apparent of which has a front and back needle bed, each continues and extending over a substantial portion of the machine length, and the carriage apparatus of which, having a stop free cam system, is movable back and forth on or above the needle bed apparatus by means of a drive apparatus and is triggered by a program for various knitting patterns. A flat bed machine has small hooks placed 45 centimeters apart. These machines are good for Fair isle patterns, cables and lace. Baby weight or sometimes event thinner yarn can be used.

- 35. TWO BAR WARP KNITTING MACHINE Warp knitting machines can be built with one or with two needle bars, thus, forming one or two stitch courses per main shaft revolution. This fact often results in confusions when describing the productivity and fabric parameters of these machines. A standardized definition of the relevant technical criteria is meant to remedy this matter.

- 36. KNITTING LINE The designation “knitting line” can also be used for one main shaft revolution. Thus, one knitting line for double bar machine consists of one stitch forming cycle, to form a course on the front and on the front and on the rear needle bar. If the thread should be interlaced on both needle bars. In this way, a stitch is usually formed on the front needle bar, under lap to the rear needle bar, one stitch on the rear needle bar and the under lap back again to the front needle bar.

- 37. CIRCULAR JACQUARD KNITTING MACHINE A jacquard pattern control mechanism for a circular knitting machine in which knitting instrumentalities are selected in accordance with a jacquard pattern and are moved between three positions, namely welt tuck and knit positions by a selected jack a rocker base a rocker bar pivotally mounted on the rocker base and rocked bar and electromagnetic selection mechanisms that attract selected portions of the rocker bar to determine to which position the knitting instrumentally will be moved. In order to produce a variety of relatively intricate stitch patterns in the knit fabric, jacquard pattern control mechanisms are commonly provided and used. Such jacquard pattern control mechanisms typically select certain knitting needles in the inactive positions.

- 38. CIRCULAR PILE KNITTING MACHINE Circular knitting machine for the production of high pile fabrics having combed-in fabrics, having a needle cylinder with displaceable mounted knitting needles defining a circular knitting field along the upper edge of the cylinder, carding device disposed along the knitting field, and an exhaust to illuminate the knitting field from within and a mirror is fastened to the exhaust for the section-wise viewing of the inside of portions of the knitting field disposed on the side of an observer.

- 39. Thank you Monika Samtani B.Sc.. In Fashion Technology 2ND Year Dezyne E’cole College