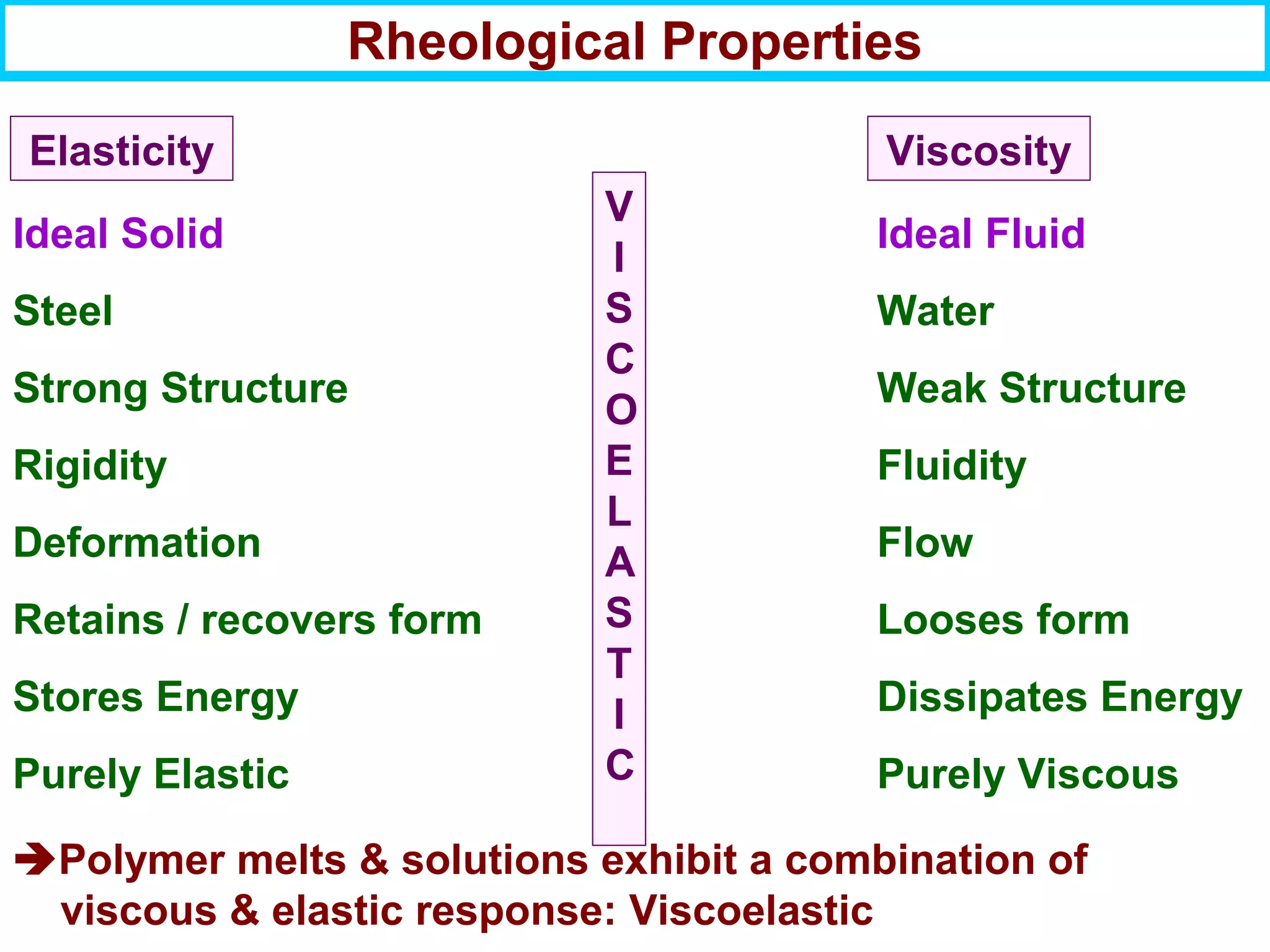

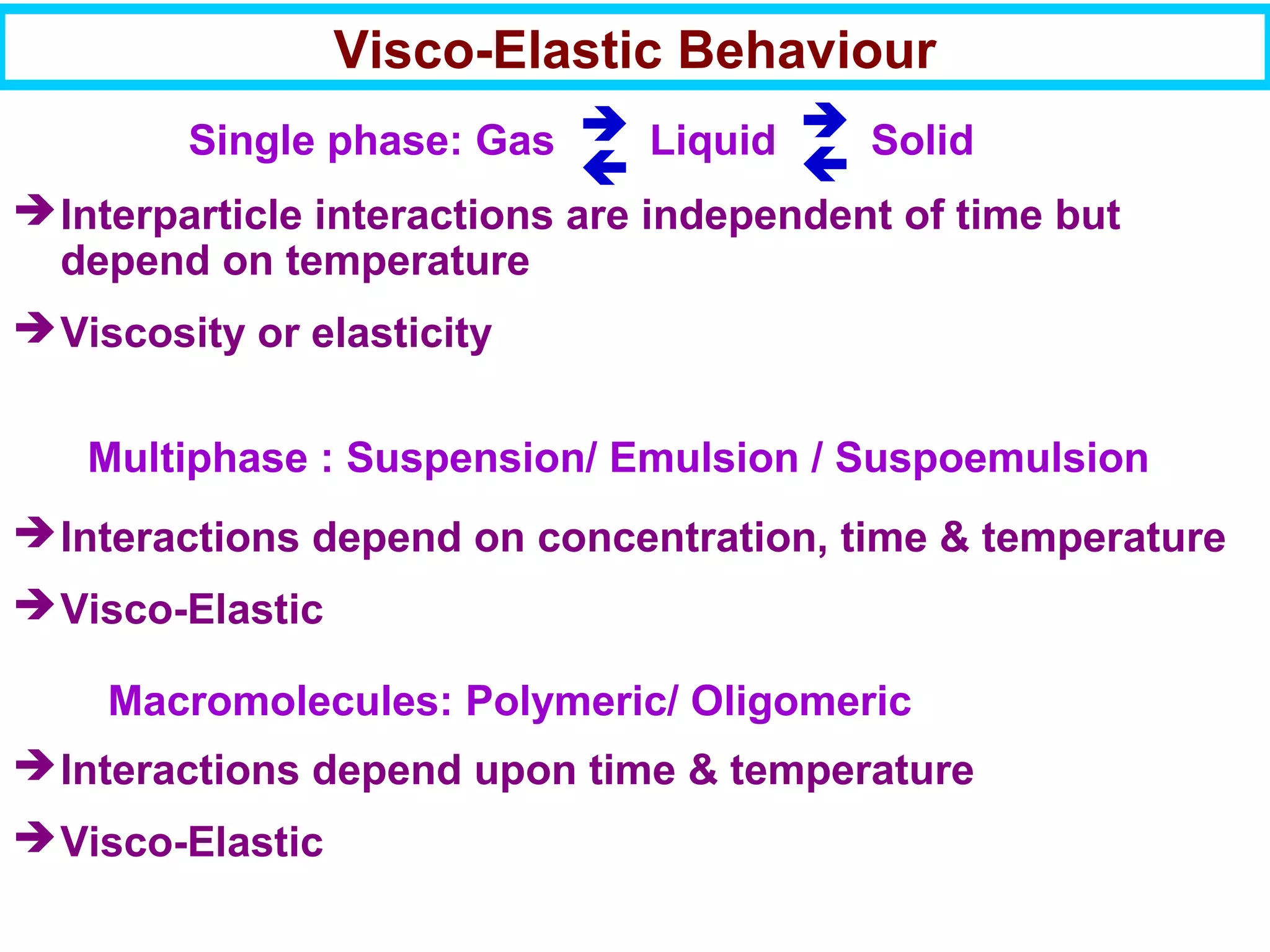

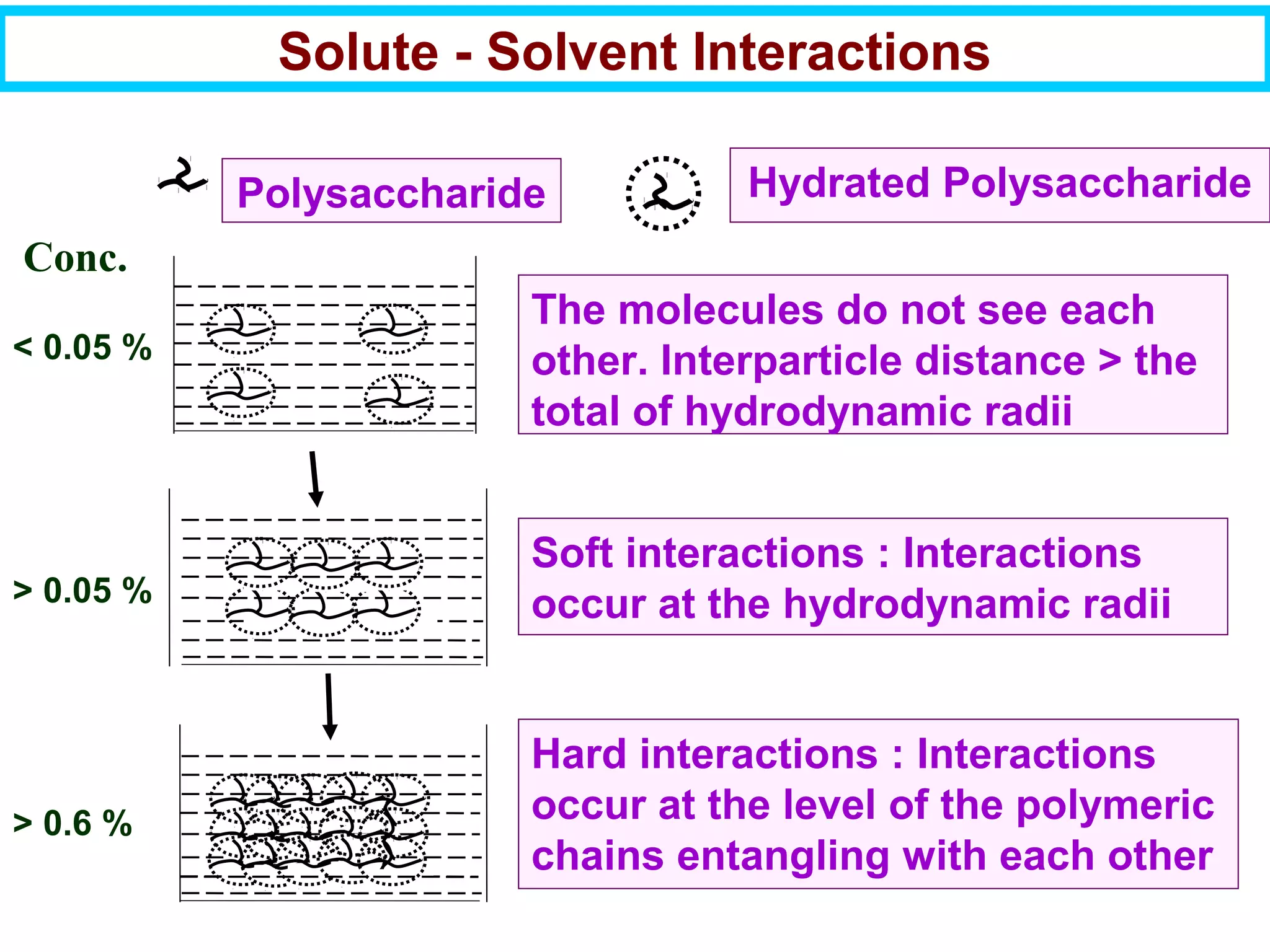

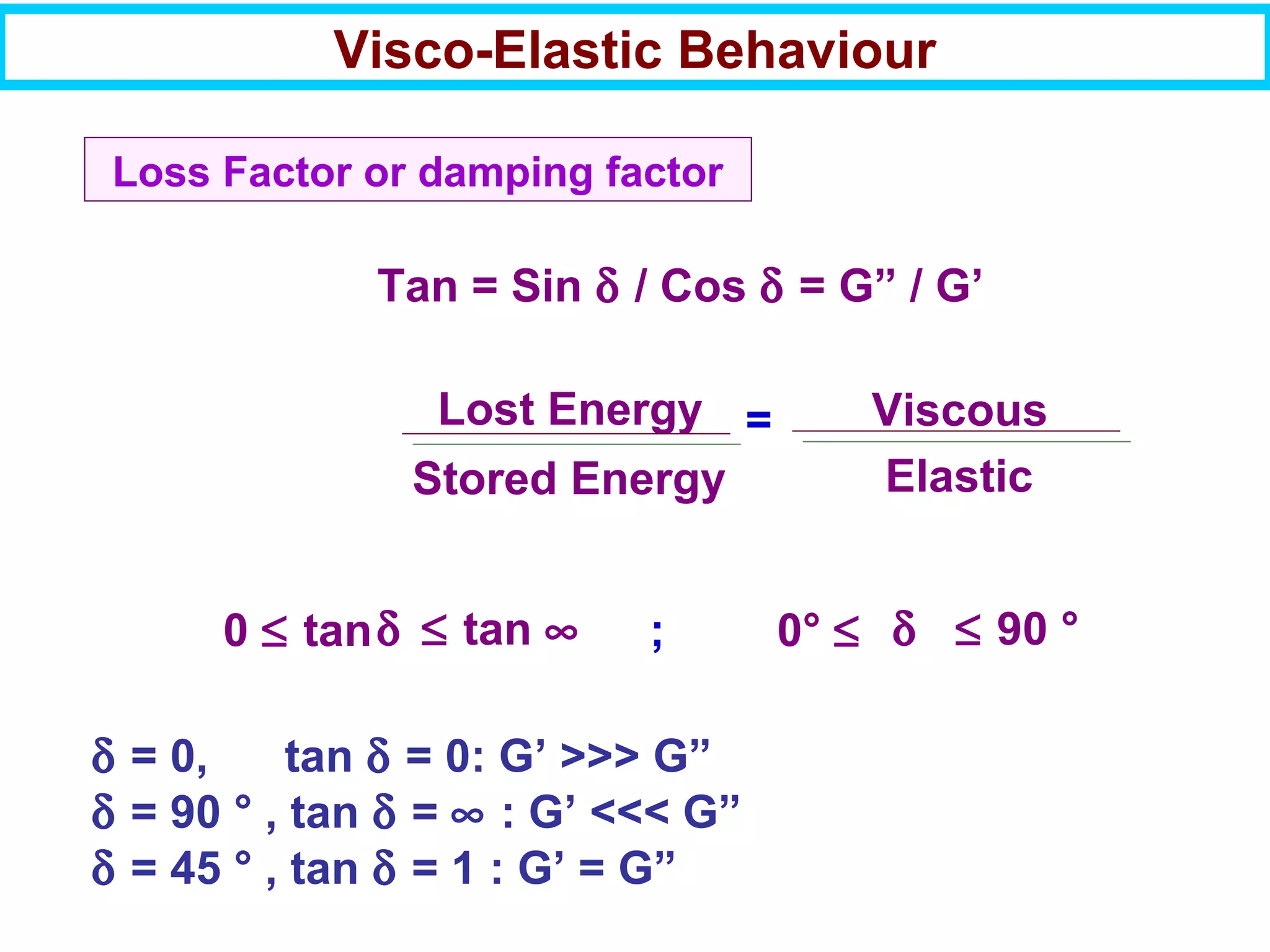

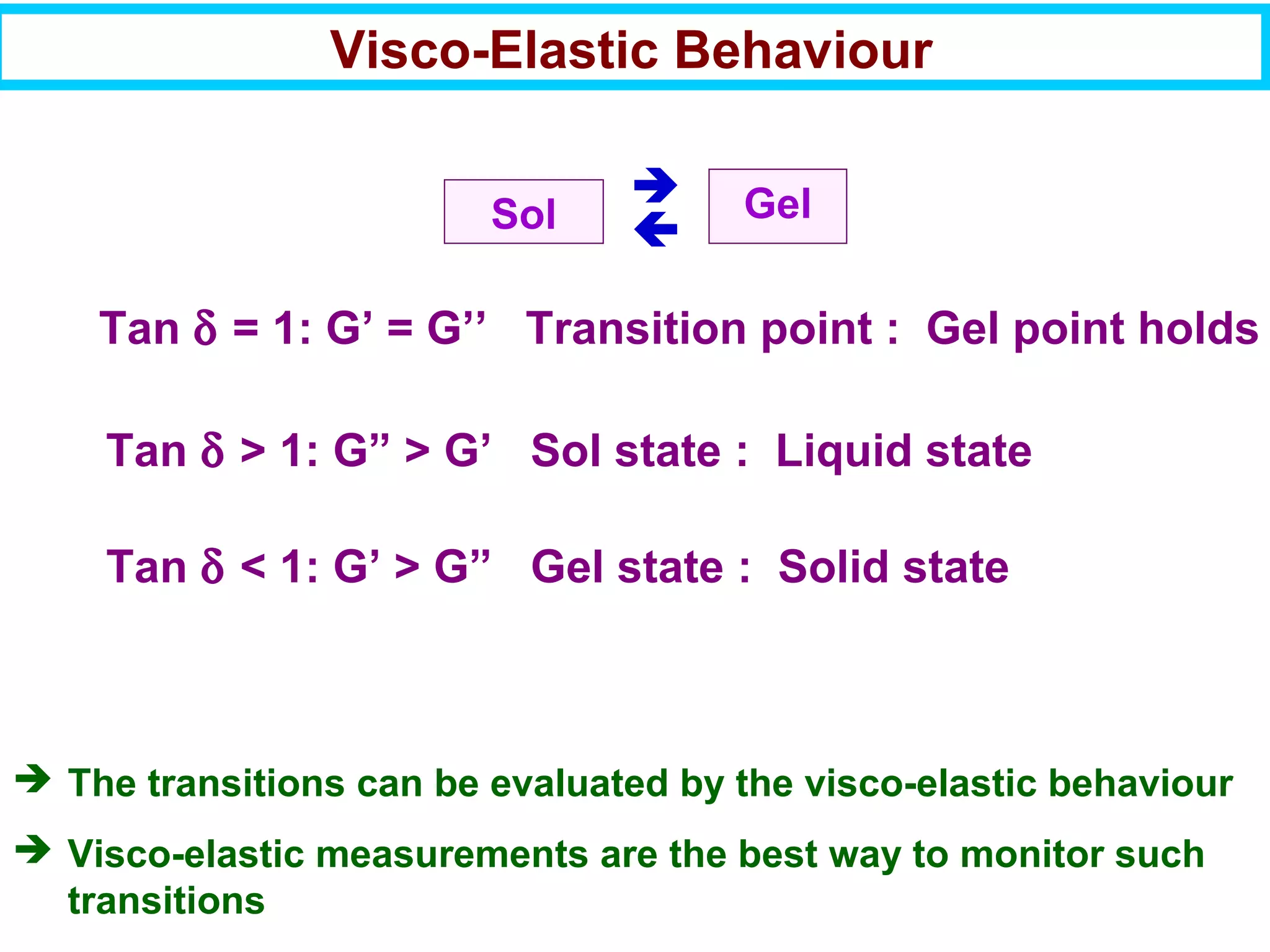

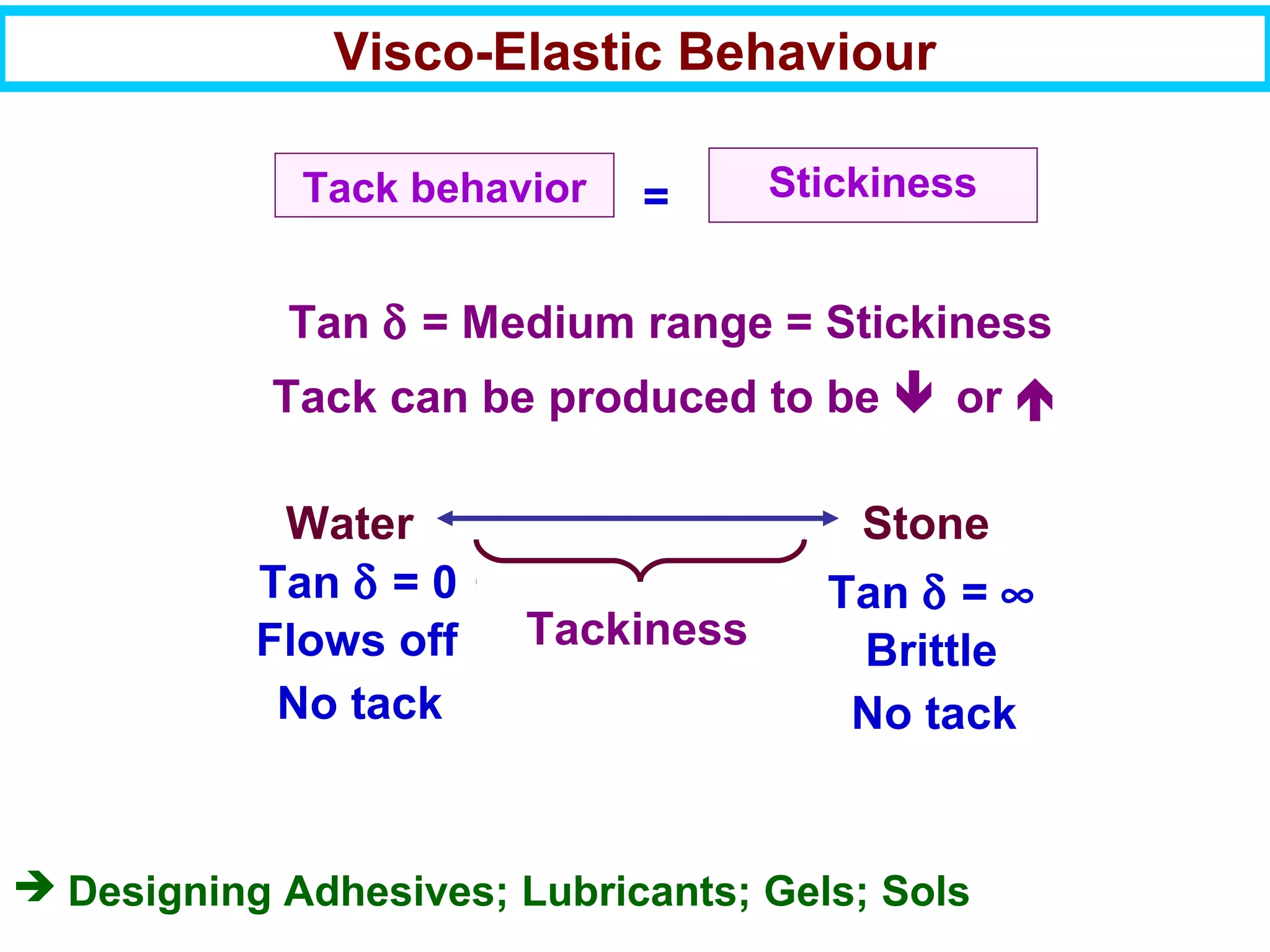

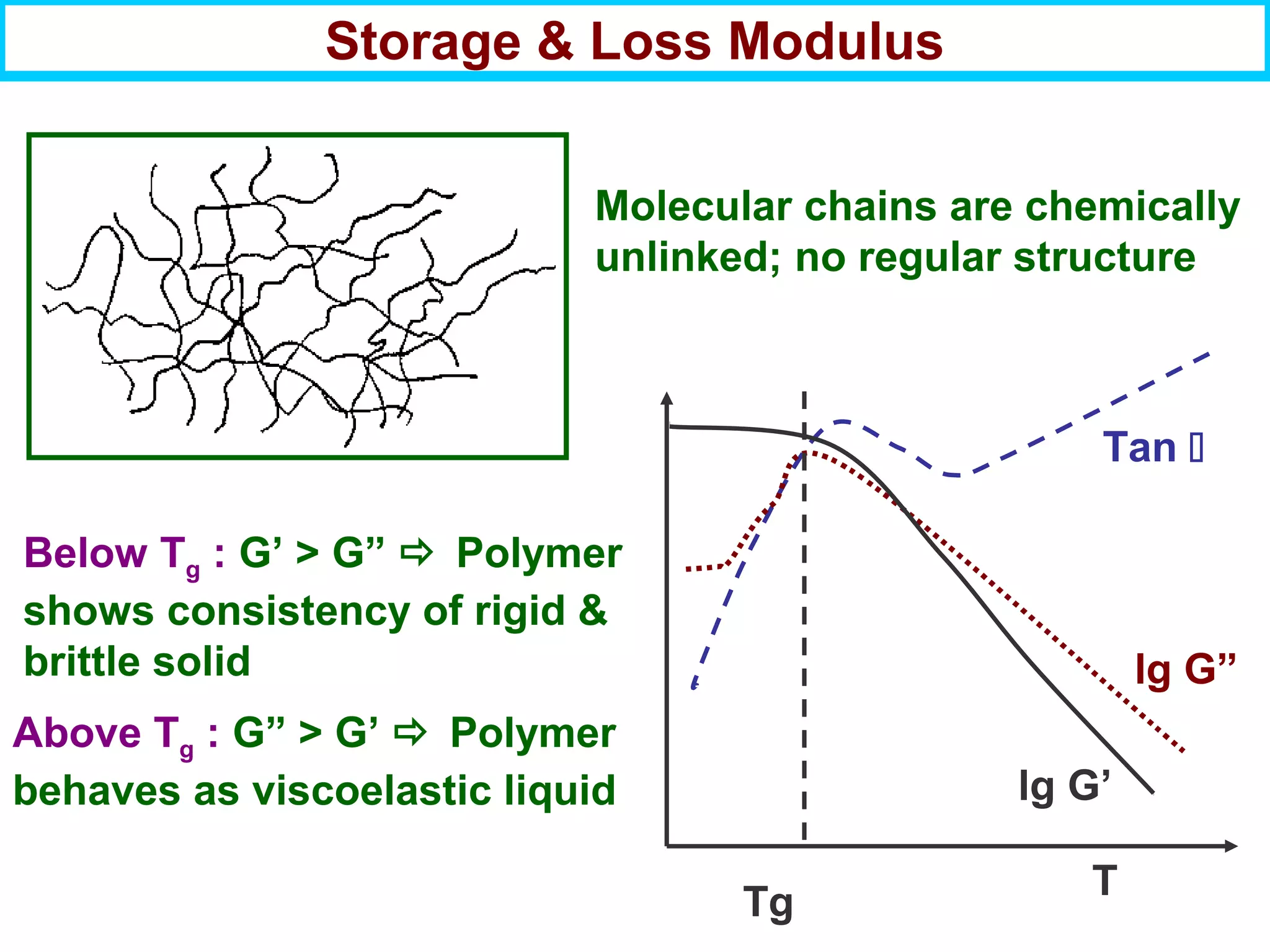

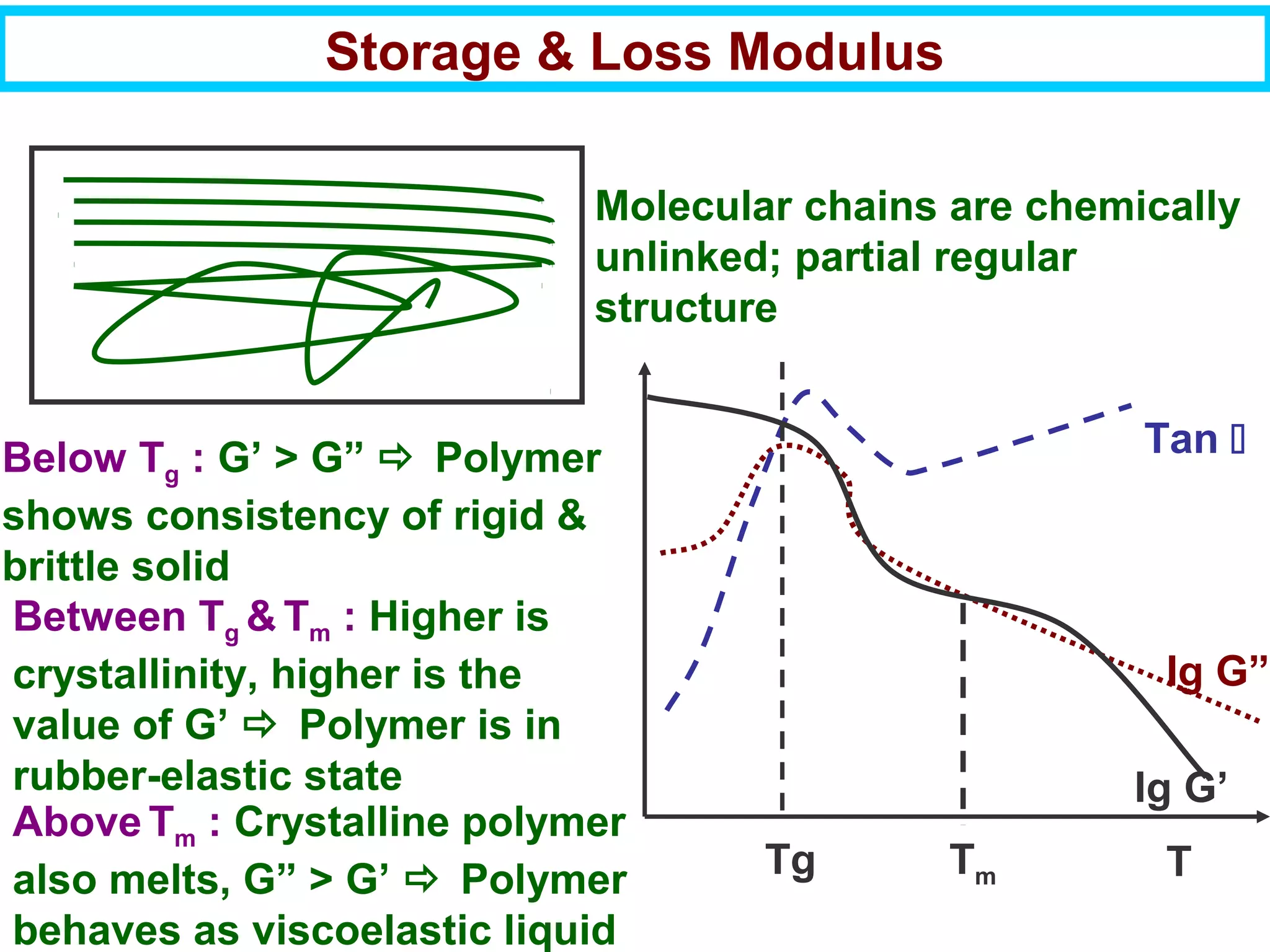

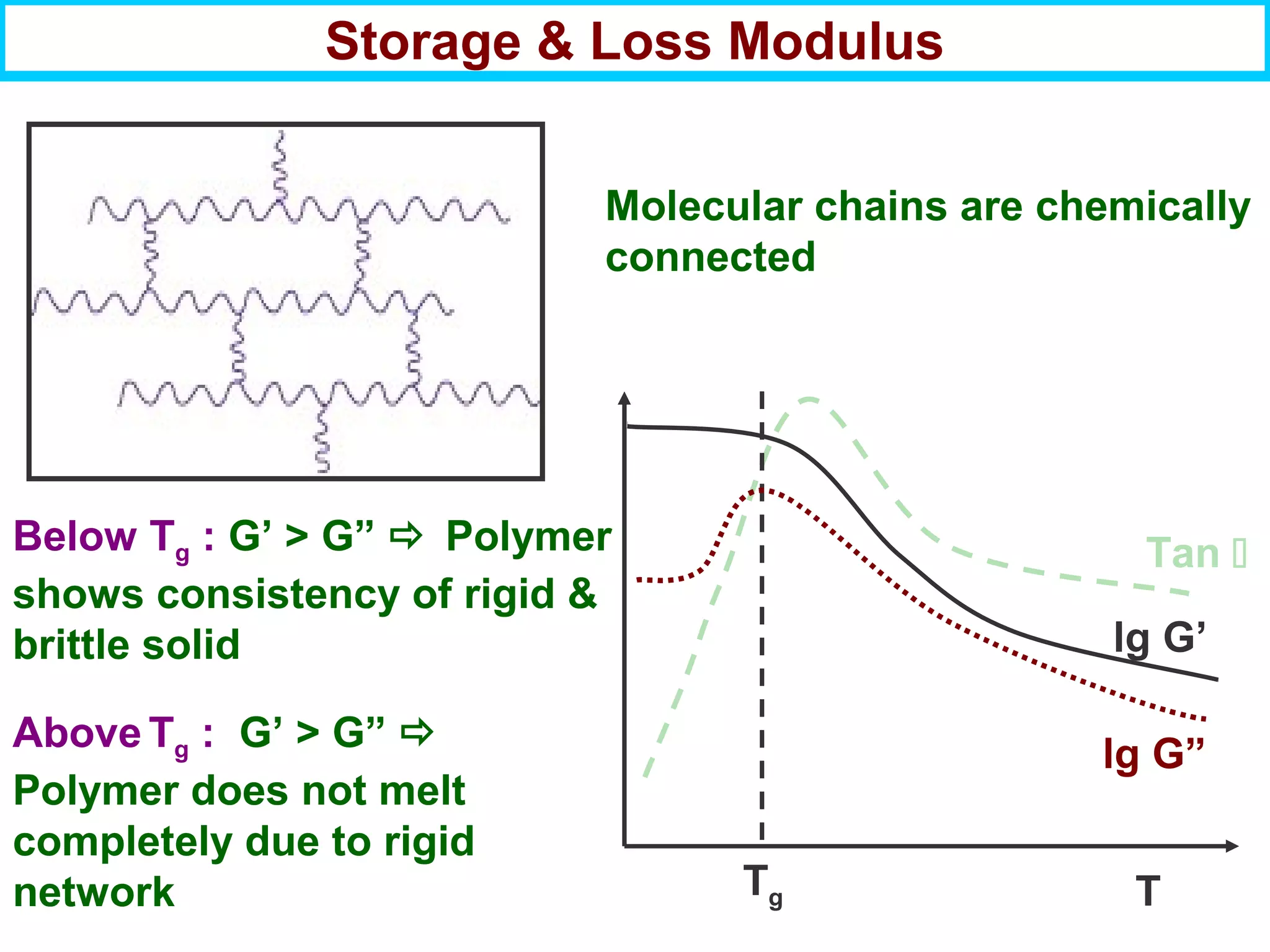

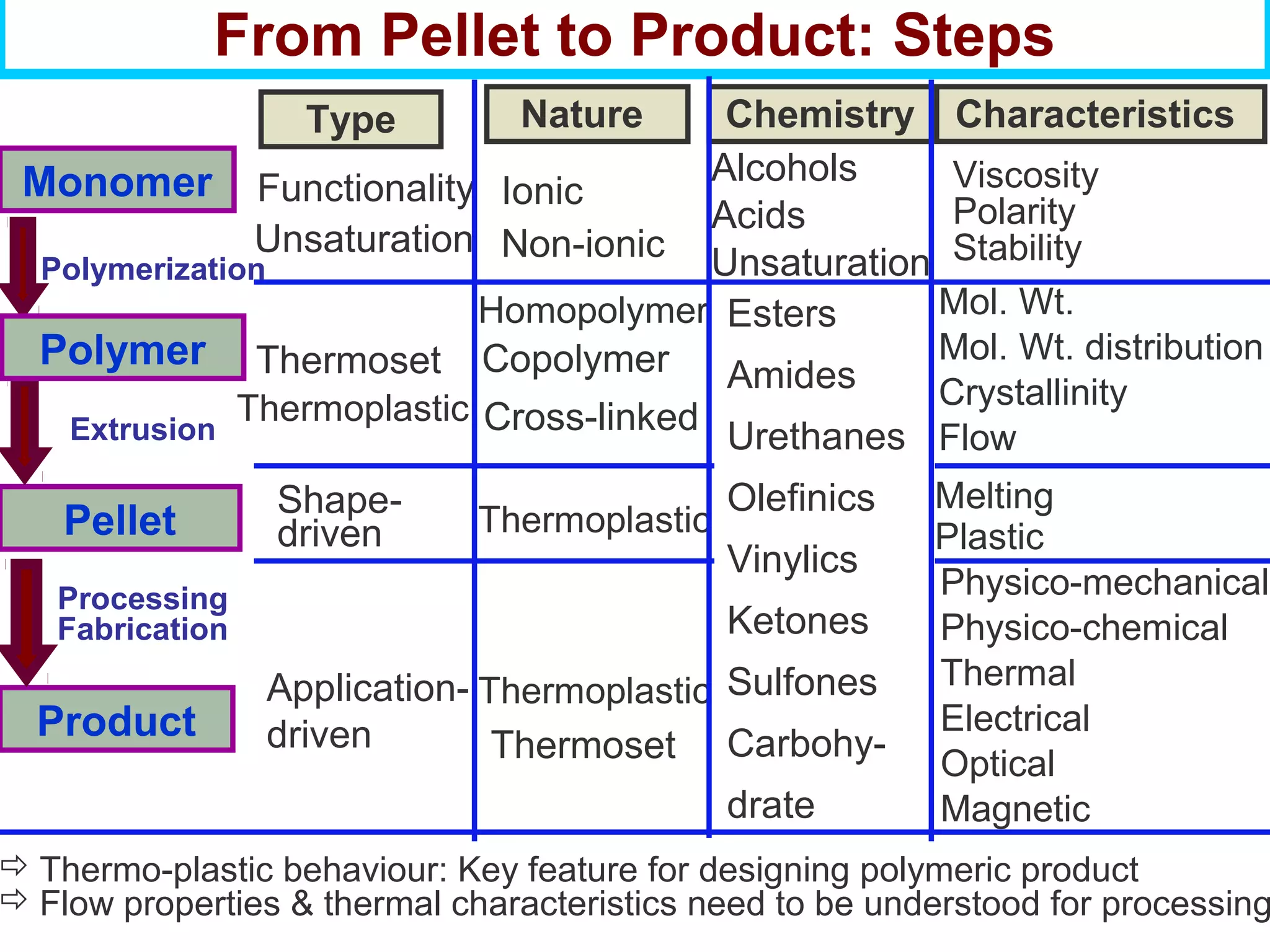

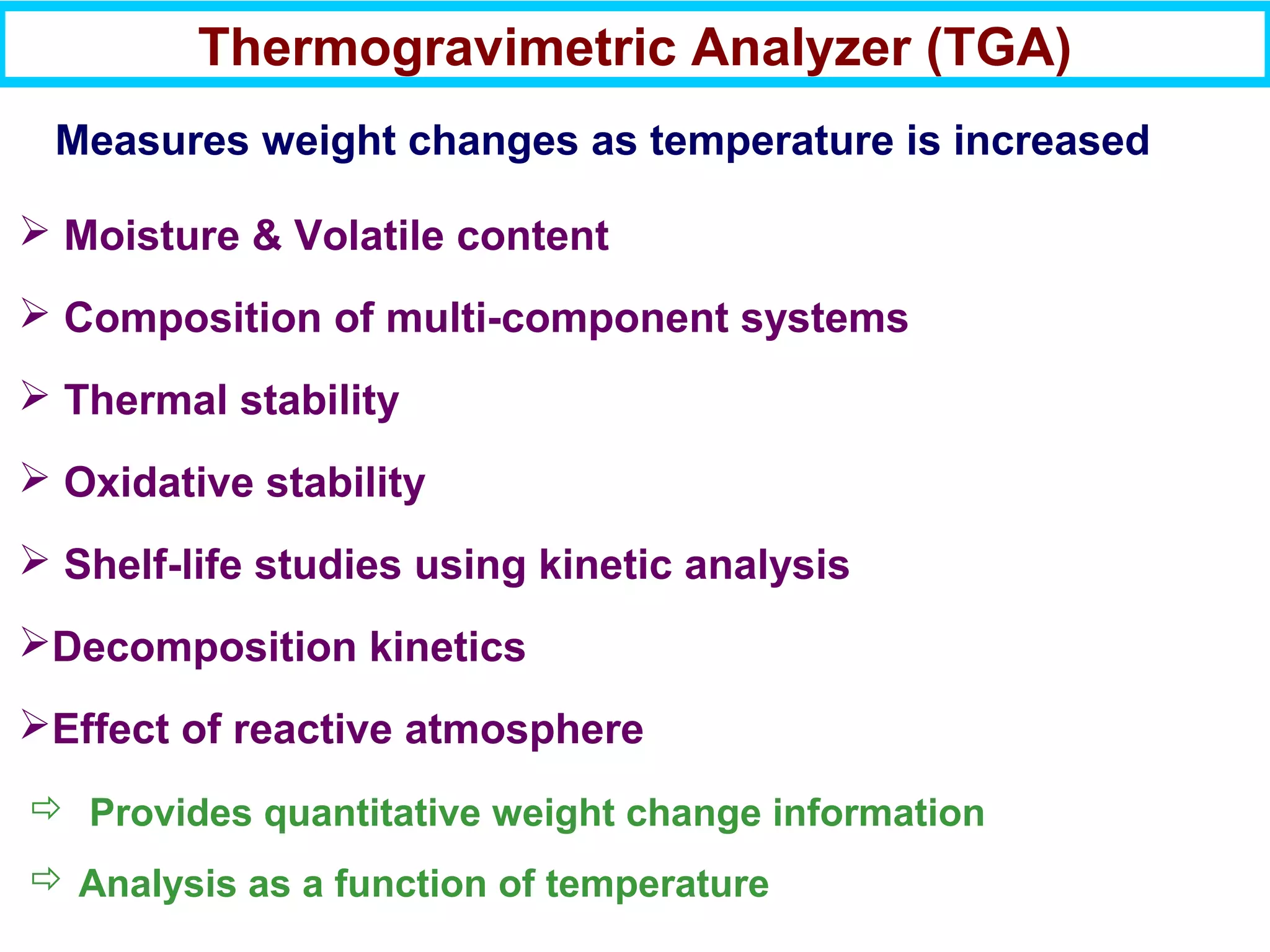

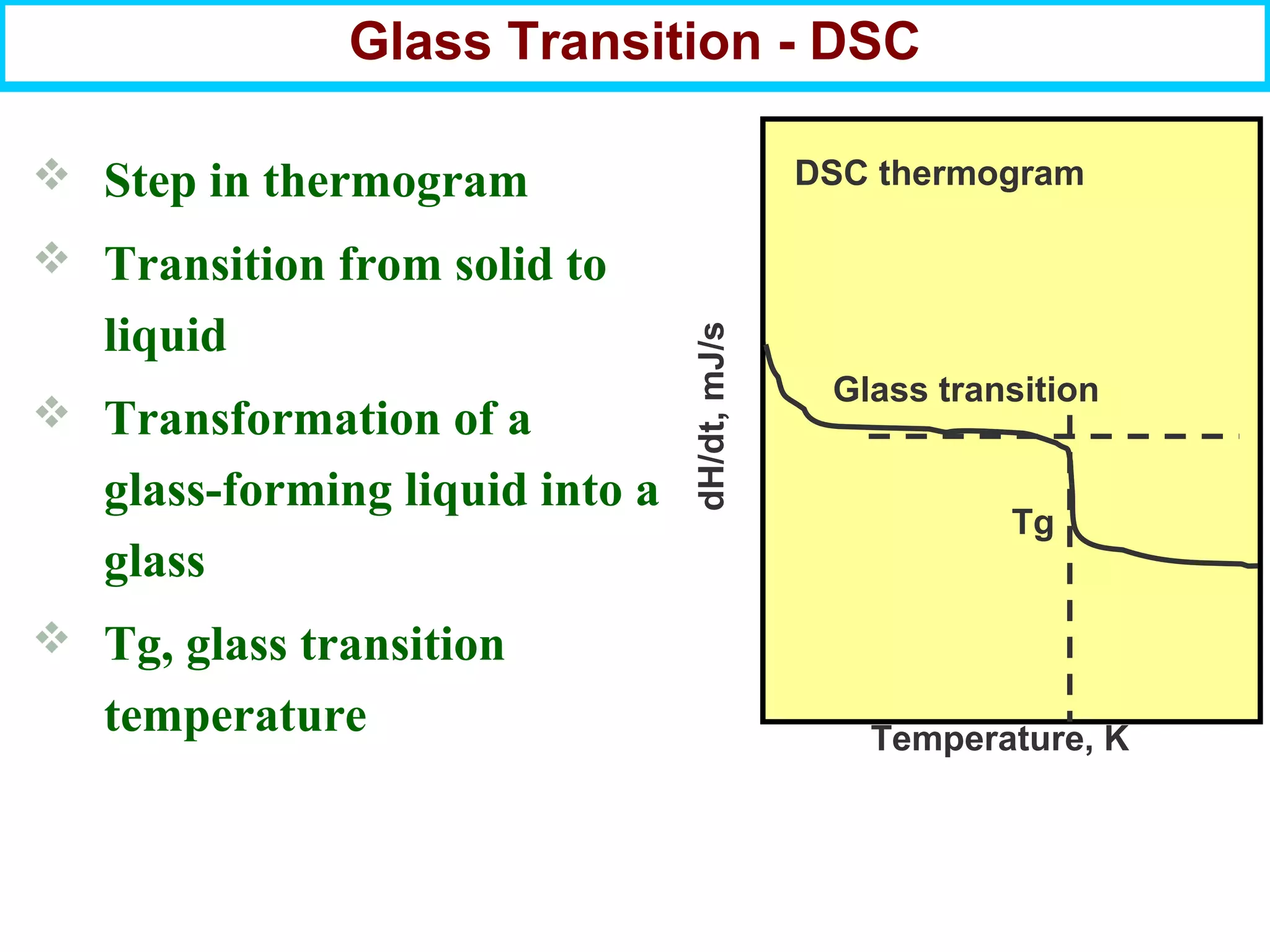

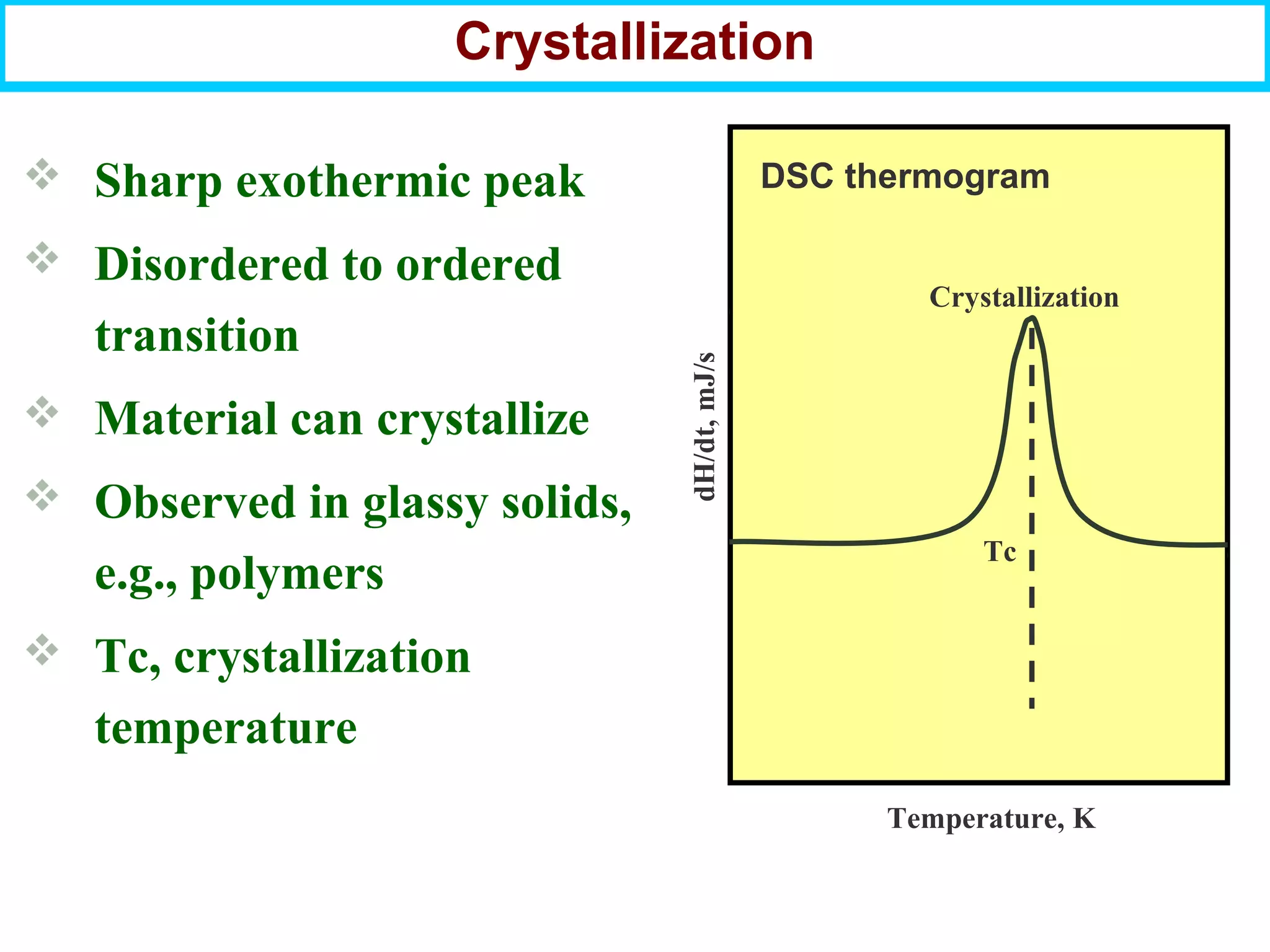

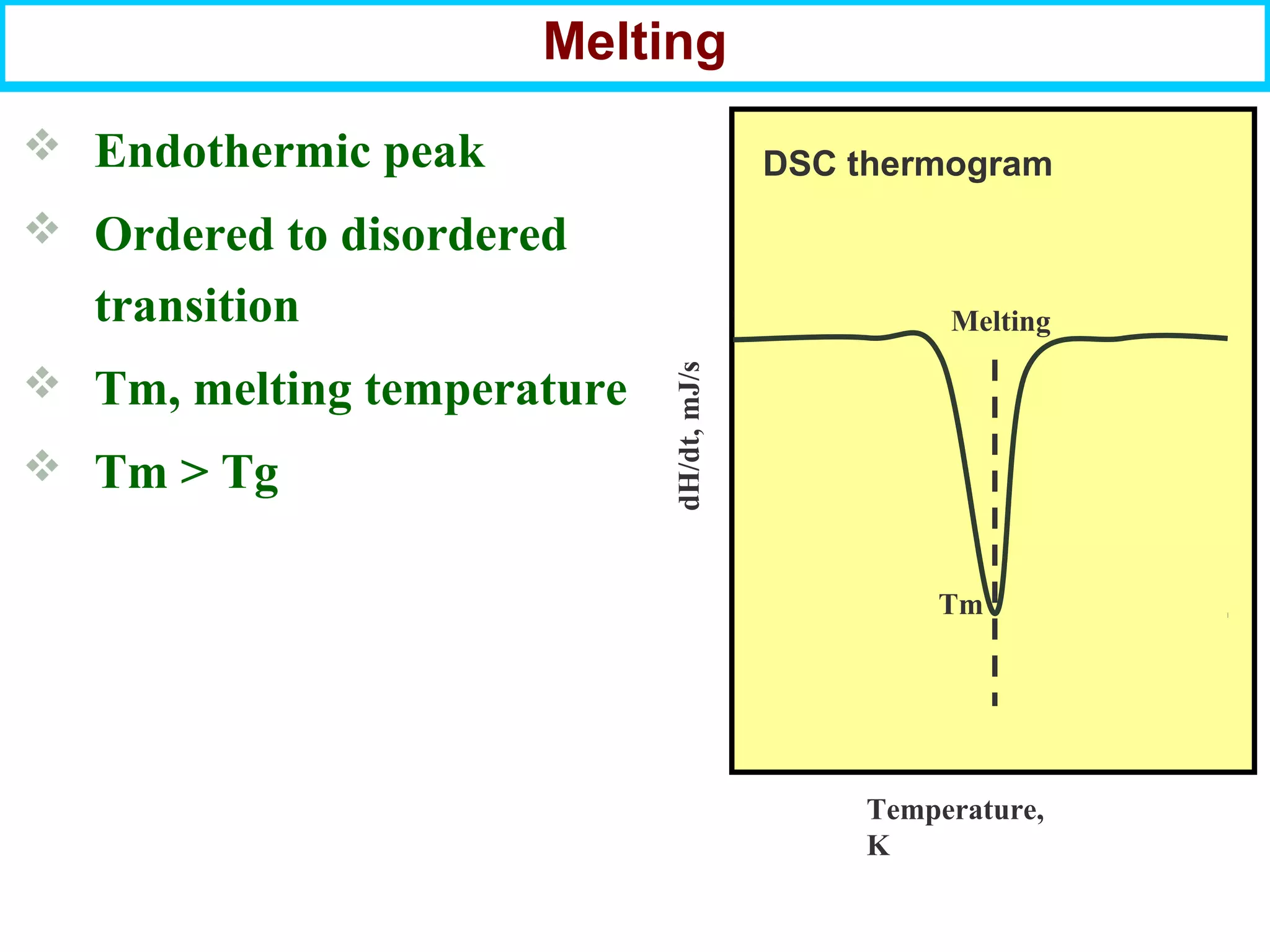

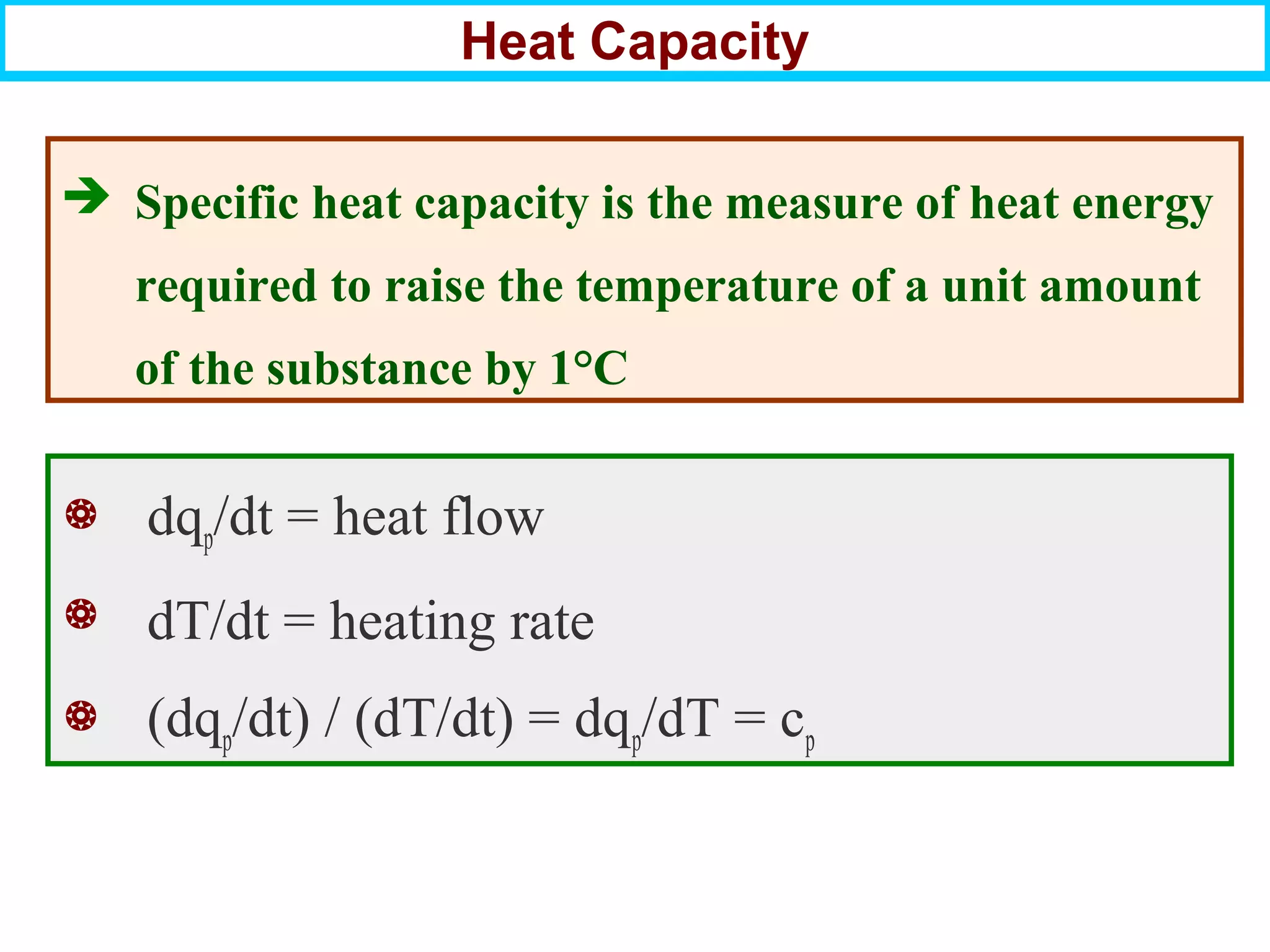

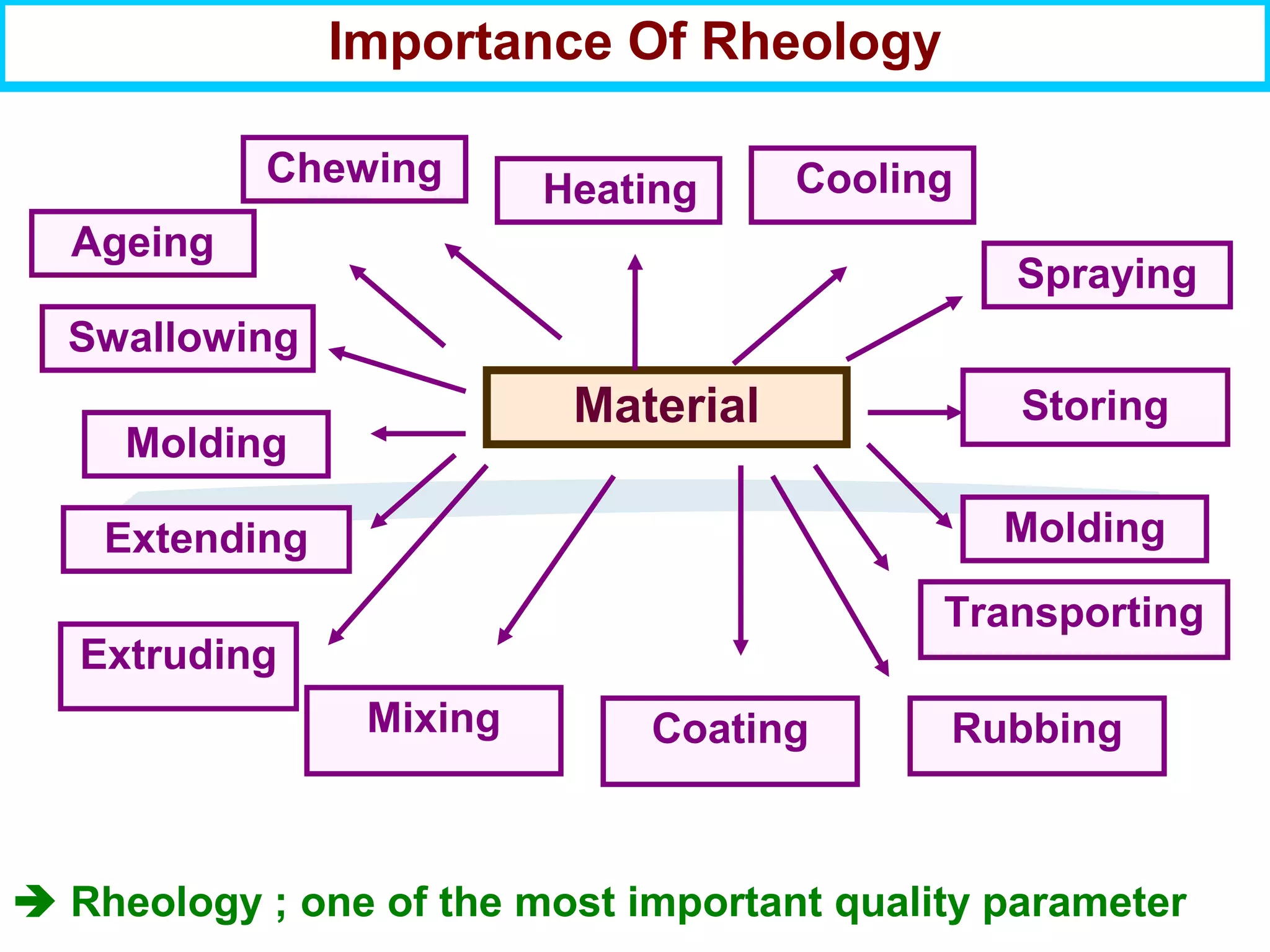

This document discusses the key steps and properties involved in transforming polymer pellets into finished products. It outlines the process from pellet to product, including polymerization, extrusion, processing, fabrication, and the resulting properties. The document emphasizes the importance of thermal and rheological analysis for understanding the flow properties and thermal characteristics needed for processing. It describes techniques like differential scanning calorimetry and thermogravimetric analysis for thermal analysis, and defines concepts like viscosity, viscoelastic behavior, and storage and loss modulus for rheological analysis. The document argues that thermal analysis combined with rheological analysis provides an advantage for process and product design.

![Newtonian

Example :Oil,Water

Shear rate γ•

[1/ S]

Shearstressτ[Pa]

Viscosity is independent of shear rate

Shear rate ∝ shear stress](https://image.slidesharecdn.com/keynote090310-140626085038-phpapp01/75/Keynote090310-14-2048.jpg)

![Non-Newtonian: Dilatant

Shear-thickening or Dilatant

Shear rate[1/S]

Shearstressτ[Pa]

Viscosity with in shear rate

Example: ceramic suspension, plastisol pastes, starch

dispersions](https://image.slidesharecdn.com/keynote090310-140626085038-phpapp01/75/Keynote090310-15-2048.jpg)

![Non-Newtonian: Pseudoplastic

Shear rate[1/ γ•

S]

Shear thinning: Example: Polymer melts, paints, glues.

Viscosity as shear rate

Material shows plasticity only after yield point

Above yield point Plasticity,below yield point elasticity

Shearstressτ[Pa]](https://image.slidesharecdn.com/keynote090310-140626085038-phpapp01/75/Keynote090310-16-2048.jpg)

![THIXOTROPY & RHEOPEXY

Time(t)

For Thixotropic

materials, viscosity

as time , at a constant

shear rate.

Example: Paraffin

oil,Pastes,cream,gels

For Rheopectic fluid ,

viscosity as time

at a constant shear

rate

Thixotropic

Rheopectic

Shearstressτ[Pa]](https://image.slidesharecdn.com/keynote090310-140626085038-phpapp01/75/Keynote090310-17-2048.jpg)