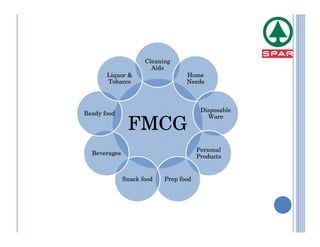

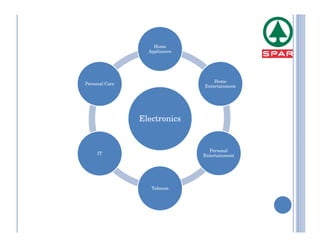

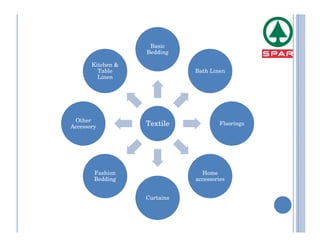

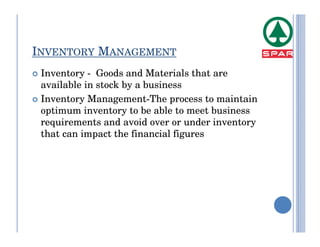

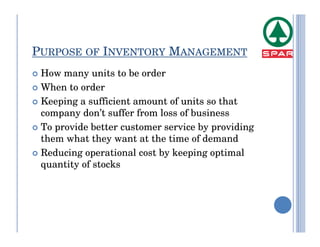

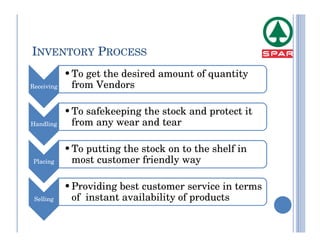

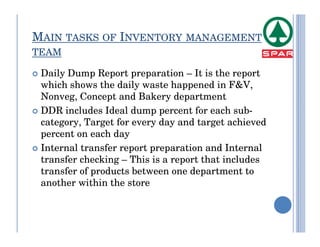

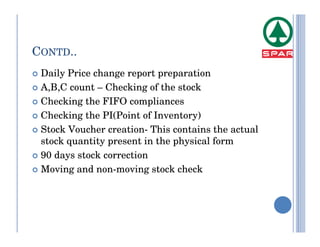

Spar is an international retail chain headquartered in the Netherlands. It operates over 12500 stores globally including 13 stores in India through a joint venture. Inventory management is important for Spar to maintain optimal stock levels, meet business needs, and avoid losses. Key tasks include daily reports, stock checks, receiving goods, and categorizing inventory. Challenges include discrepancies, damaged goods, and space constraints.