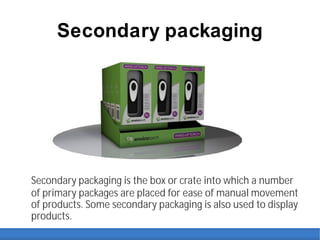

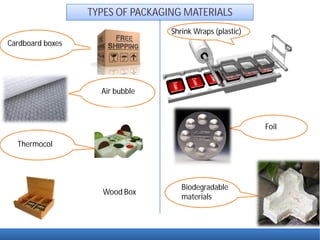

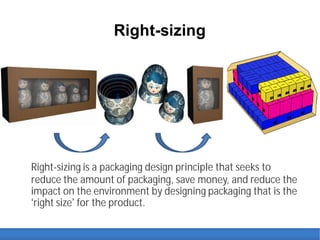

The document discusses the importance and various types of packaging, including primary, secondary, and transit packaging, and their roles in product containment, communication, and logistics. It emphasizes the benefits of good packaging, such as cost-effectiveness, environmental friendliness, and improved customer service. Additionally, it mentions principles like right-sizing to minimize waste and enhance efficiency in packaging solutions.