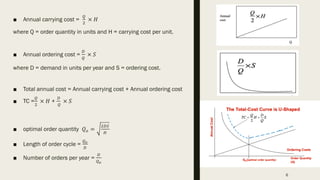

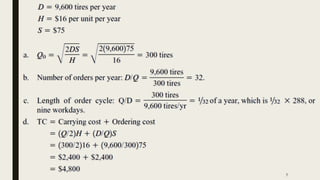

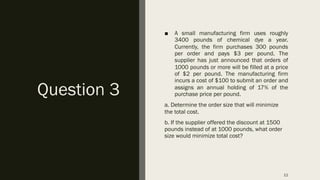

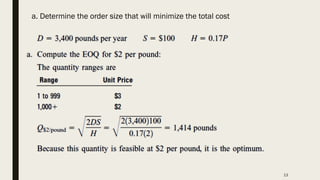

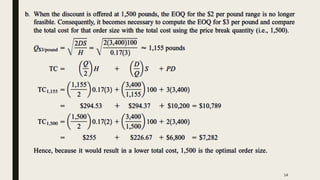

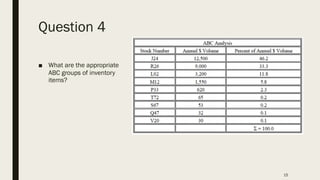

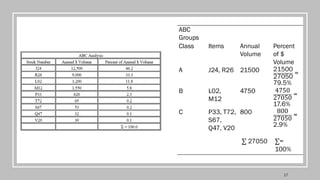

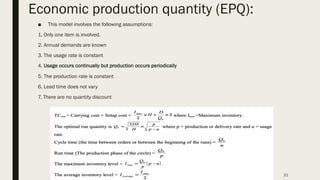

The document discusses inventory management concepts including economic order quantity (EOQ) and ABC analysis. It provides examples to calculate EOQ, total annual inventory costs, and optimal order size considering quantity discounts.

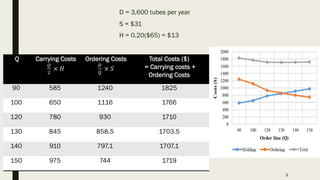

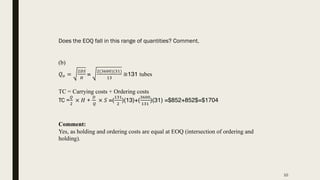

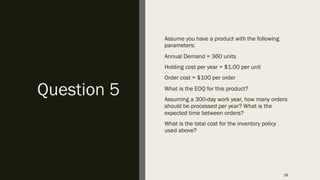

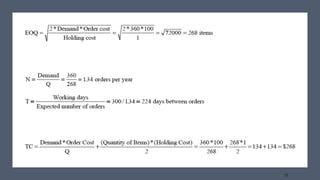

For a product with annual demand of 360 units, holding cost of $1 per unit, and order cost of $100, the EOQ is calculated as 120 units. Assuming a 300-day work year, 12 orders would be placed annually with an average time between orders of 25 days. The total annual inventory cost for this policy is $1,200.

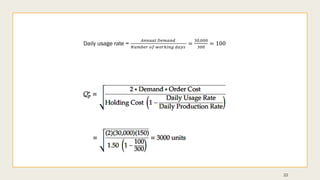

For a firm producing 30,000 fire extinguishers annually requiring one handle each, the optimal production order quantity considering an annual carrying cost of $