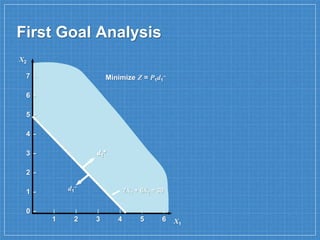

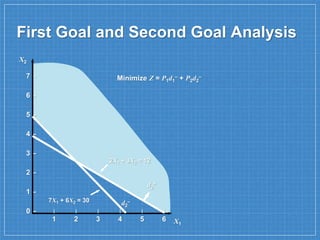

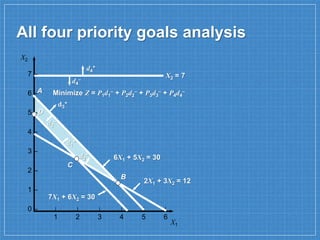

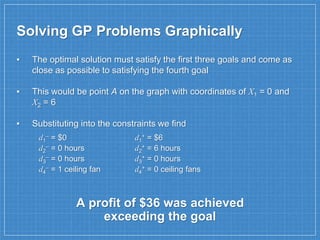

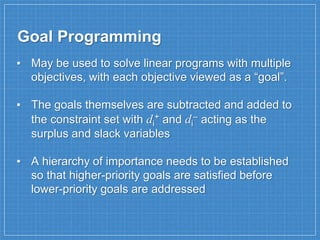

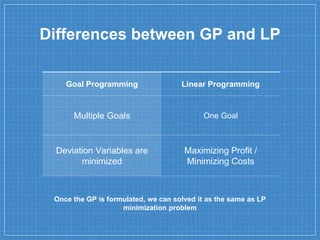

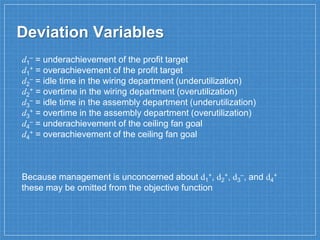

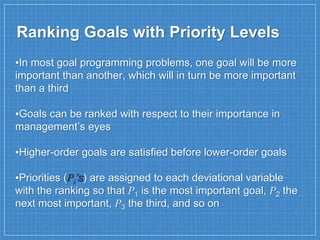

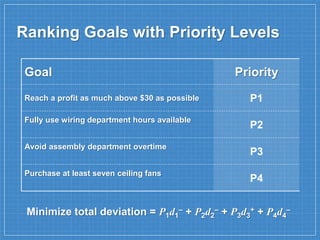

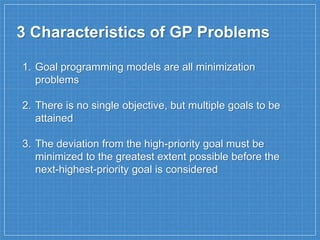

The document discusses goal programming, which is used to solve linear programs with multiple objectives viewed as goals. It describes goal programming as attempting to reach a satisfactory level of multiple objectives by minimizing deviations between goals and what can actually be achieved given constraints. An example problem involves a hardware company with goals of achieving a $30 profit, fully utilizing wiring hours, avoiding assembly overtime, and producing at least 7 ceiling fans. The goal programming model for this problem is formulated and graphically solved to satisfy the higher priority goals as closely as possible before lower goals.

![LP Formulation

[Maximize Profit]

Z = 7x1 + 6x2

[Subject To]

2x1 + 3x2 <= 12 (Wiring Hours)

6x1 + 5x2 <= 30 (Assembly Hours)

x1,x2 >= 0

[Let]

x1 = # of chandeliers produced

x2 = # of ceiling fans produced](https://image.slidesharecdn.com/goalprogramming-150911073618-lva1-app6891/85/Goal-Programming-8-320.jpg)

![[Minimize Total Deviation]

d1

– + d2

– + d3

+ + d4

–

[Subject To]

7x1 + 6x2 + d1

– – d1

+ = 30 (Profit Constraint)

2x1 + 3x2 + d2

– – d2

+ = 12 (Wiring Hours)

6x1 + 5x2 + d3

– – d3

+ = 30 (Assembly Hours)

x2 + d4

– – d4

+ = 7 (Ceiling Fan Constraint)

All xi,di variables >= 0

GP Model](https://image.slidesharecdn.com/goalprogramming-150911073618-lva1-app6891/85/Goal-Programming-12-320.jpg)

![[Minimize Total Deviation]

P1d1

– + P2d2

– + P3d3

+ + P4d4

–

[Subject To]

7x1 + 6x2 + d1

– – d1

+ = 30 (Profit Constraint)

2x1 + 3x2 + d2

– – d2

+ = 12 (Wiring Hours)

6x1 + 5x2 + d3

– – d3

+ = 30 (Assembly Hours)

x2 + d4

– – d4

+ = 7 (Ceiling Fan Constraint)

All xi,di variables >= 0

Recalling GP Model](https://image.slidesharecdn.com/goalprogramming-150911073618-lva1-app6891/85/Goal-Programming-16-320.jpg)