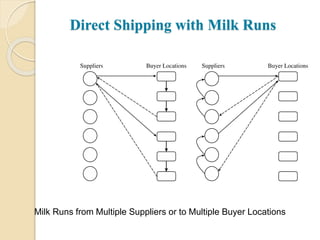

This document discusses transportation modes and their role in supply chain strategy. It describes various transportation modes like air, truck, rail, water, and intermodal and discusses key issues for each. It also covers different transportation network design options like direct shipment, distribution centers, cross-docking and milk runs. Finally, it discusses trade-offs between transportation cost, inventory cost and customer responsiveness when designing transportation networks.