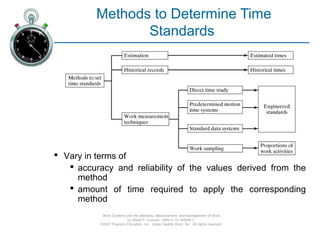

This document discusses methods for measuring work including direct time study, predetermined motion time systems, and standard data systems. It explains that setting accurate time standards is important for determining labor costs, staffing needs, and worker performance evaluations. The most accurate methods involve direct observation and measurement of workers to set baseline time standards.