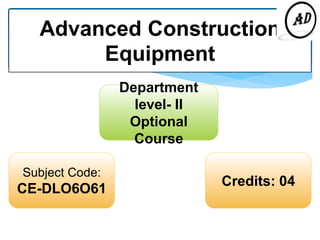

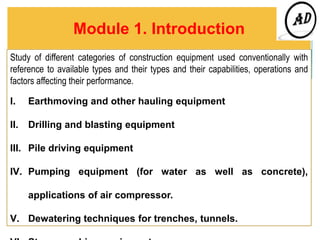

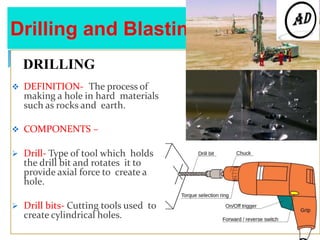

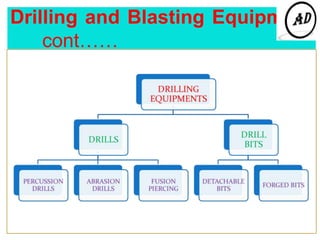

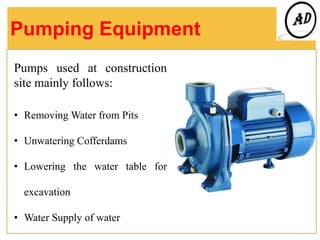

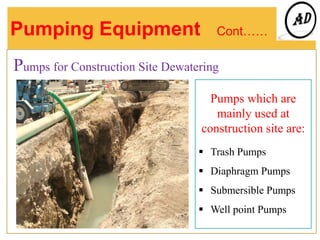

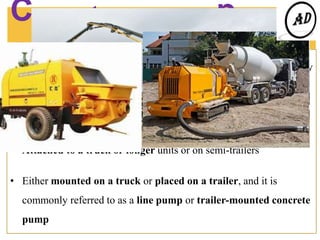

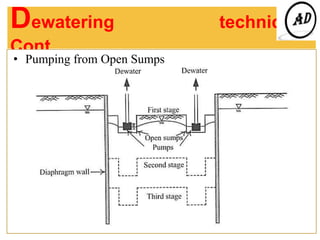

The document is a detailed outline of a lecture on advanced construction equipment, focusing on various types of machinery and techniques used in large civil engineering projects. It covers objectives, outcomes, and a comprehensive syllabus including topics like earthmoving equipment, drilling and blasting equipment, and concrete pumping equipment. The course aims to equip students with the knowledge to select and utilize the appropriate equipment based on project needs and to understand modern construction methodologies.