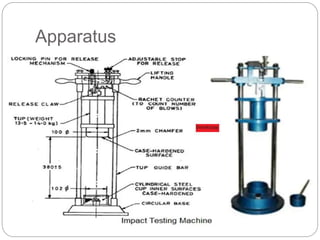

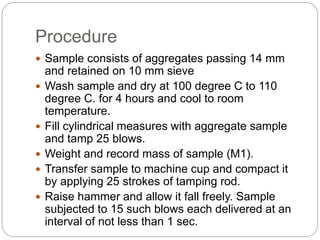

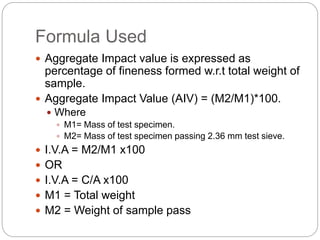

This document describes the procedure to test the impact value of aggregates according to ASTM C125. The test involves compacting a sample of aggregates passing a 14mm sieve and retained on a 10mm sieve in a cup. The cup is dropped 15 times from a height, after which the material passing a 2.36mm sieve is weighed. The impact value is calculated as the percentage of material passing the 2.36mm sieve relative to the total sample weight. A value between 10-20% is considered very strong and suitable for use in concrete and road construction. The results of testing three samples are reported, with an average impact value of 13.42% indicating very strong aggregates.