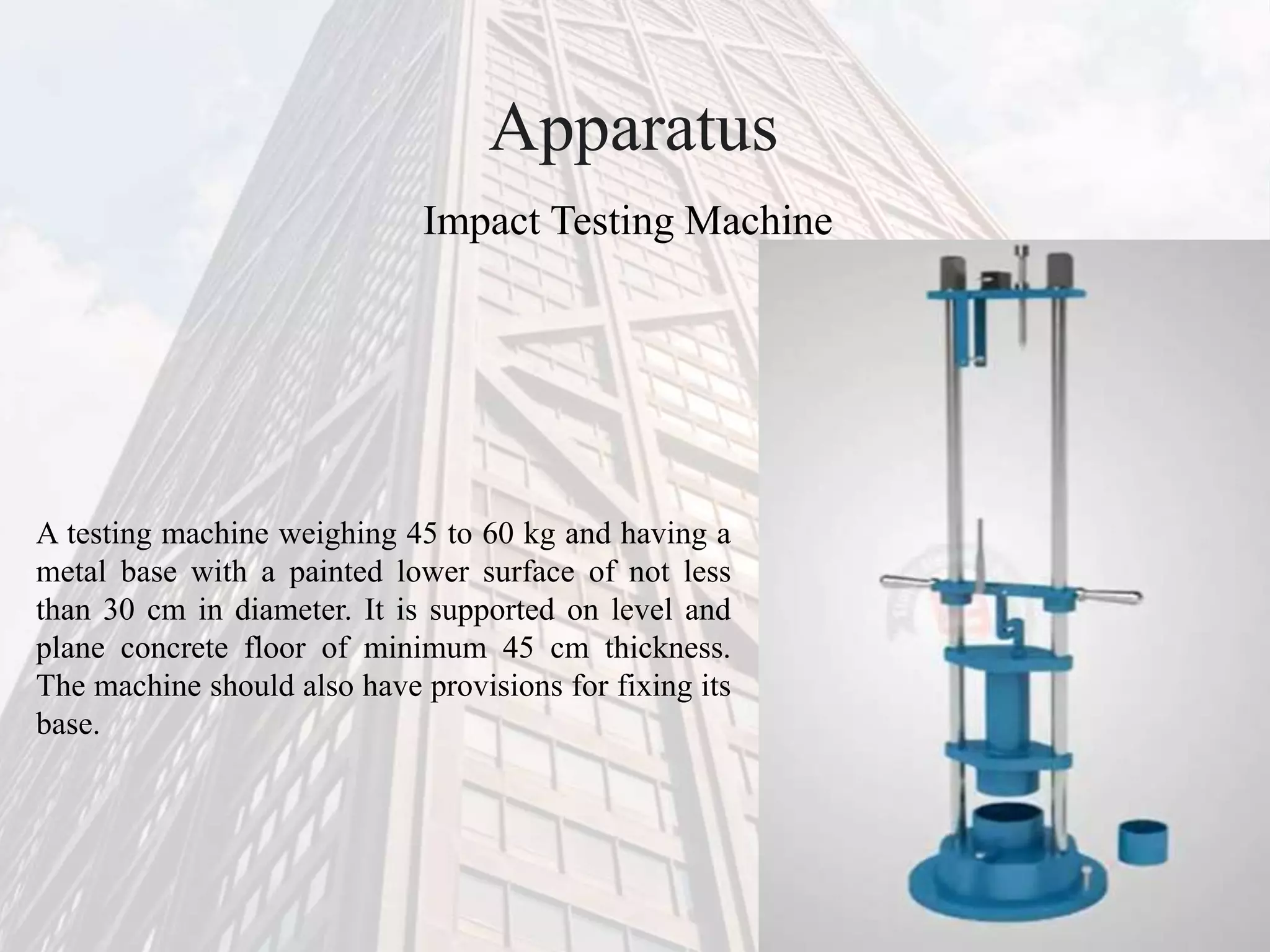

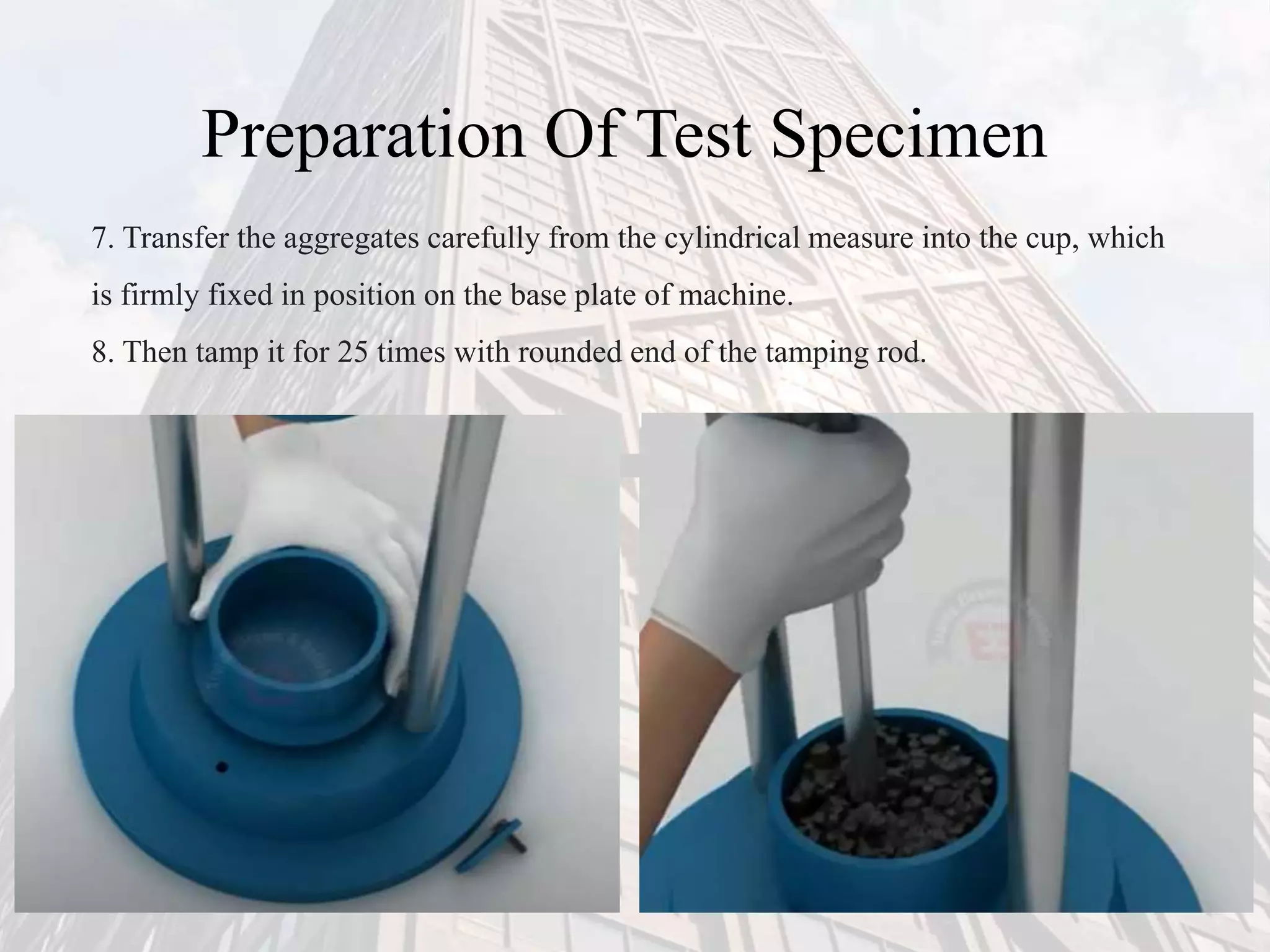

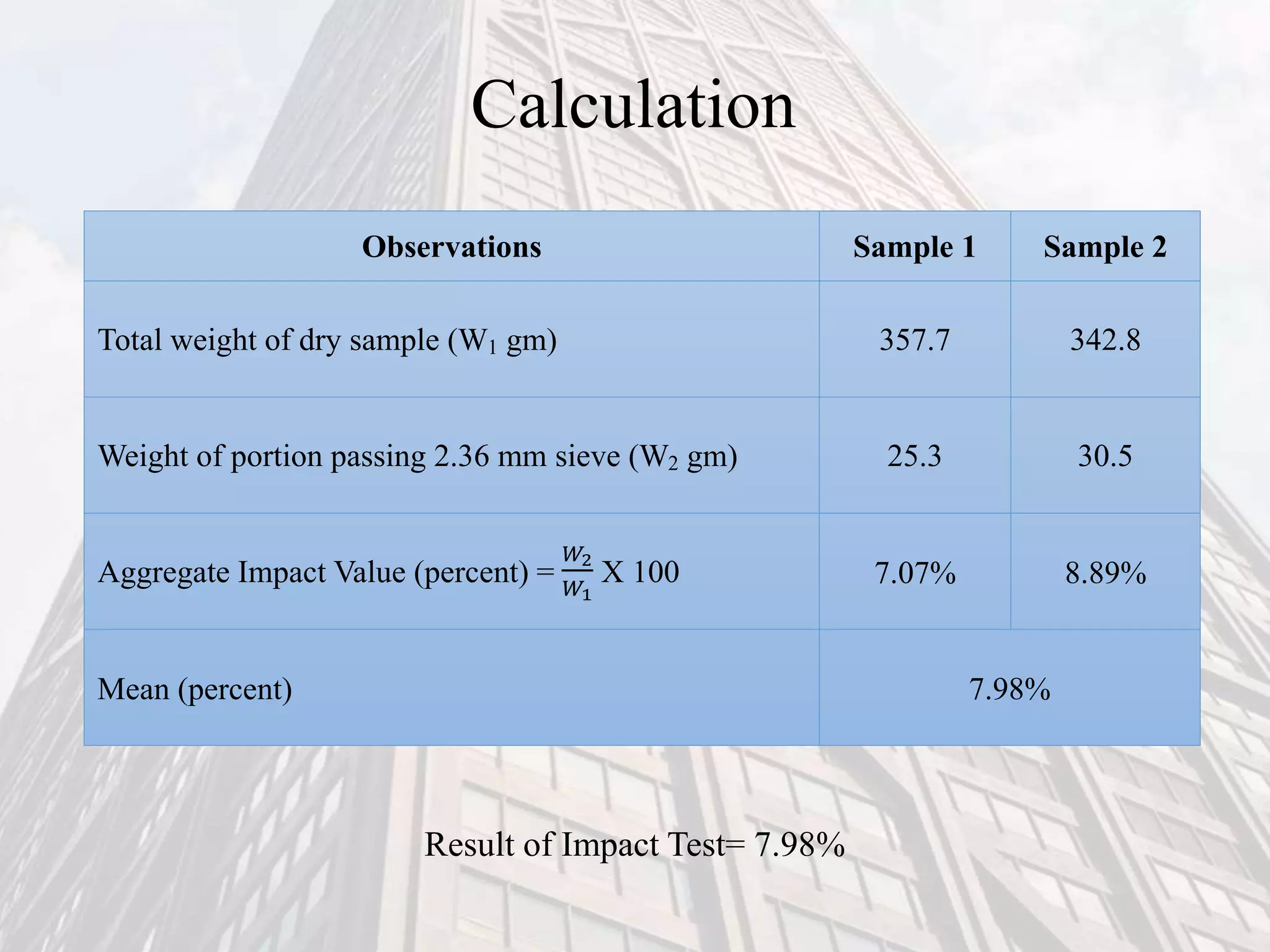

The document outlines an experiment on the aggregate impact value conducted by the Civil Engineering Department at Dhaka International University, which measures the quality of aggregates for highway pavement construction. It details the apparatus used, the procedure for conducting the impact test, and provides results indicating that the mean aggregate impact value is 7.98%, categorizing the aggregates as strong for road surfacing. The significance of these tests is to ensure the durability of aggregates against abrasion and impact loads in construction.