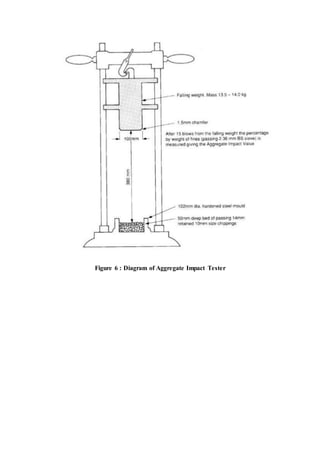

This document outlines a procedure to determine the aggregate impact value (AIV) of road construction aggregates. The AIV test involves compacting a sample of aggregates, subjecting it to 15 blows from a hammer, and calculating the percentage of fines generated that pass through a 2.36mm sieve. An AIV below 10% indicates an aggregate is exceptionally strong for road surfacing, while above 35% is too weak. The summarized experiment found an AIV of 15.82% for a tested sample, indicating it is sufficiently strong.