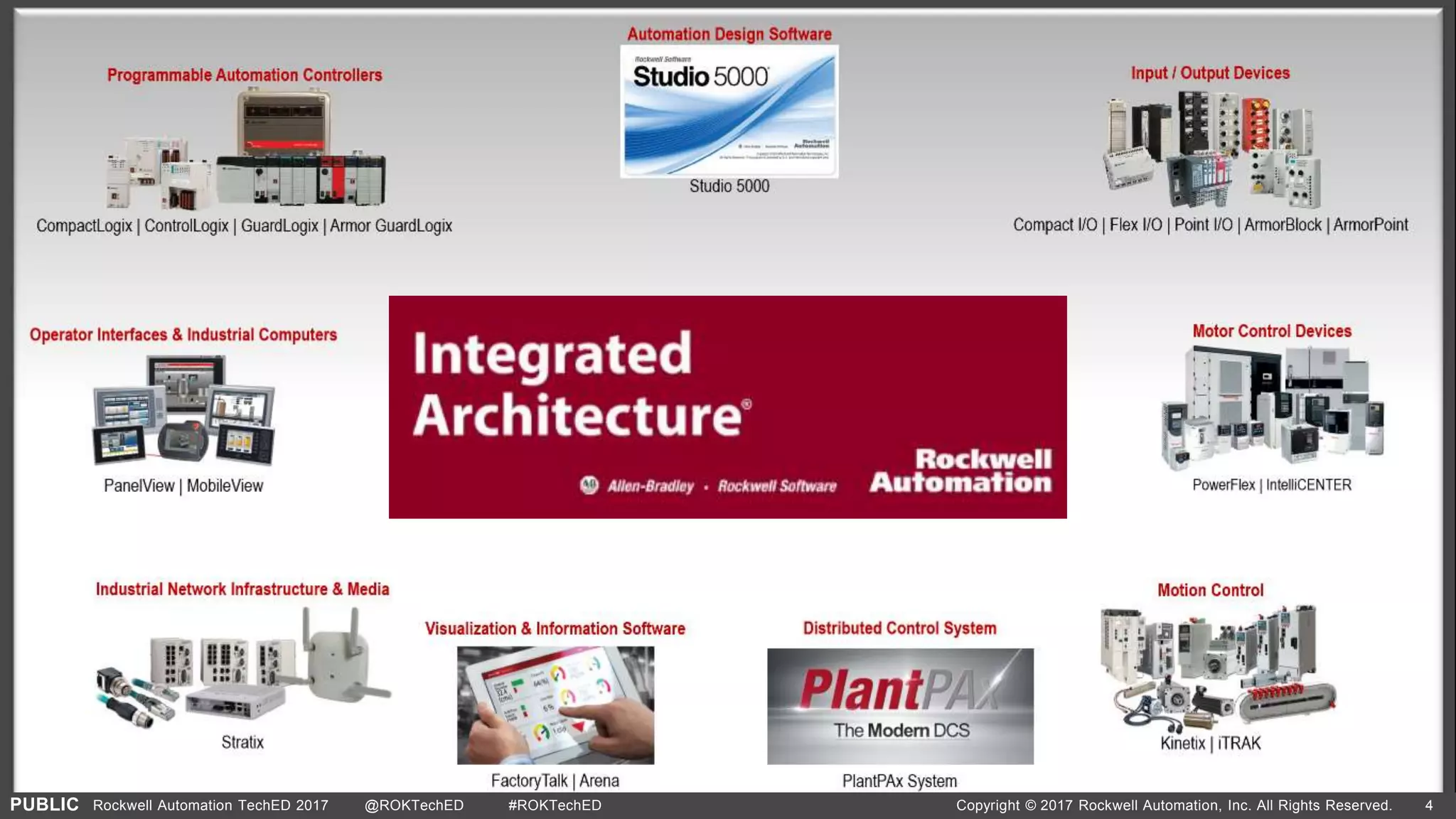

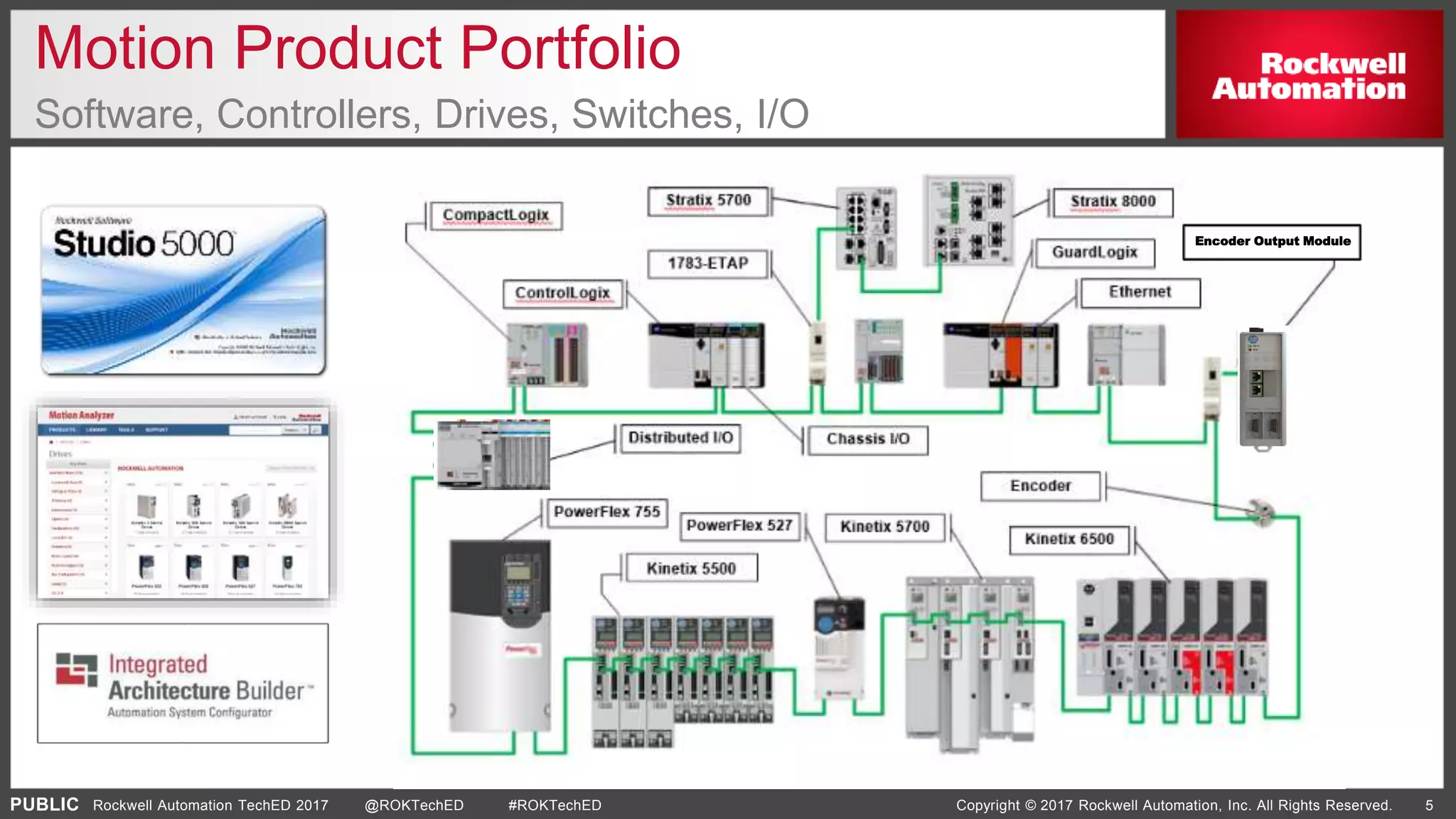

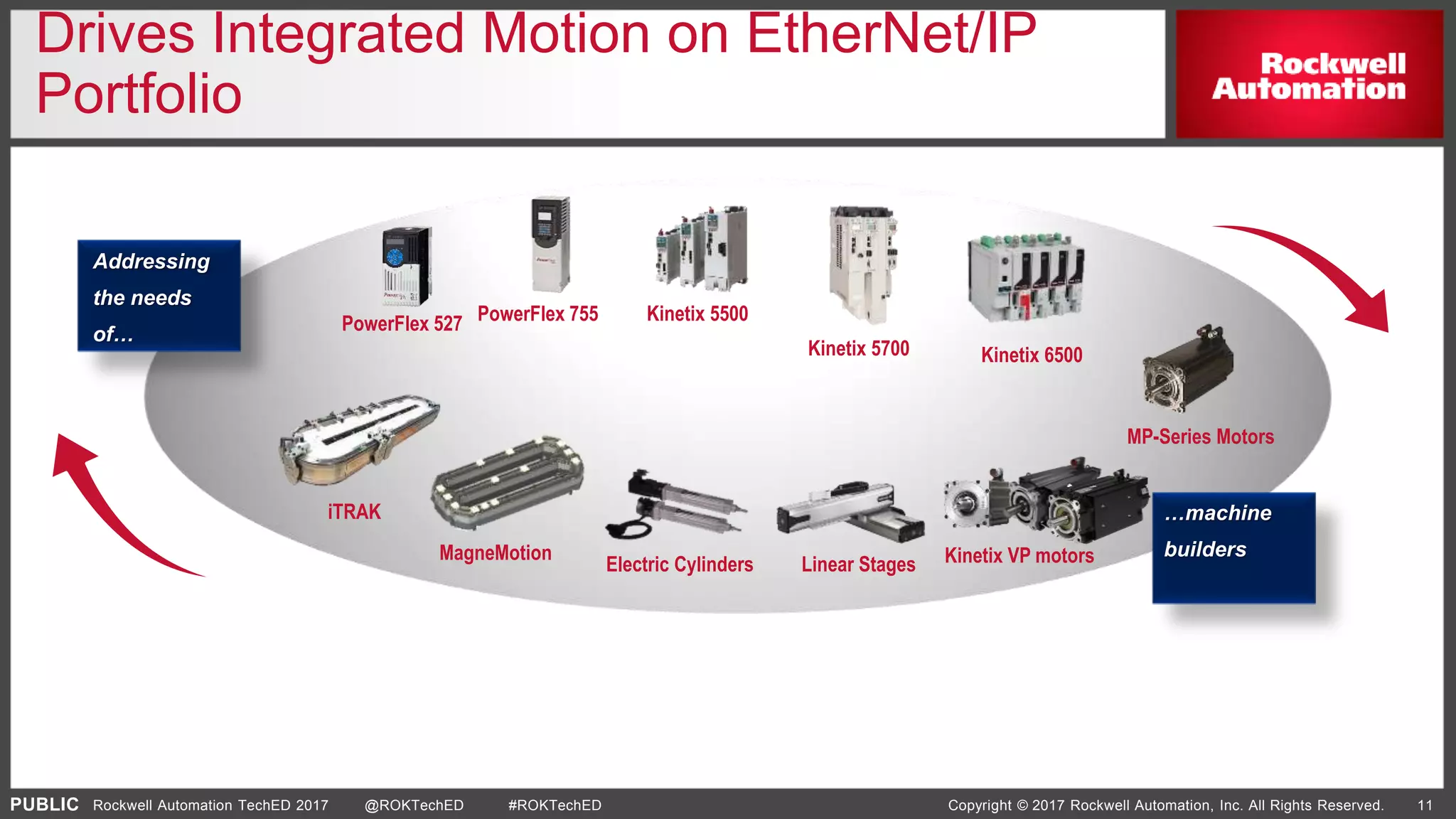

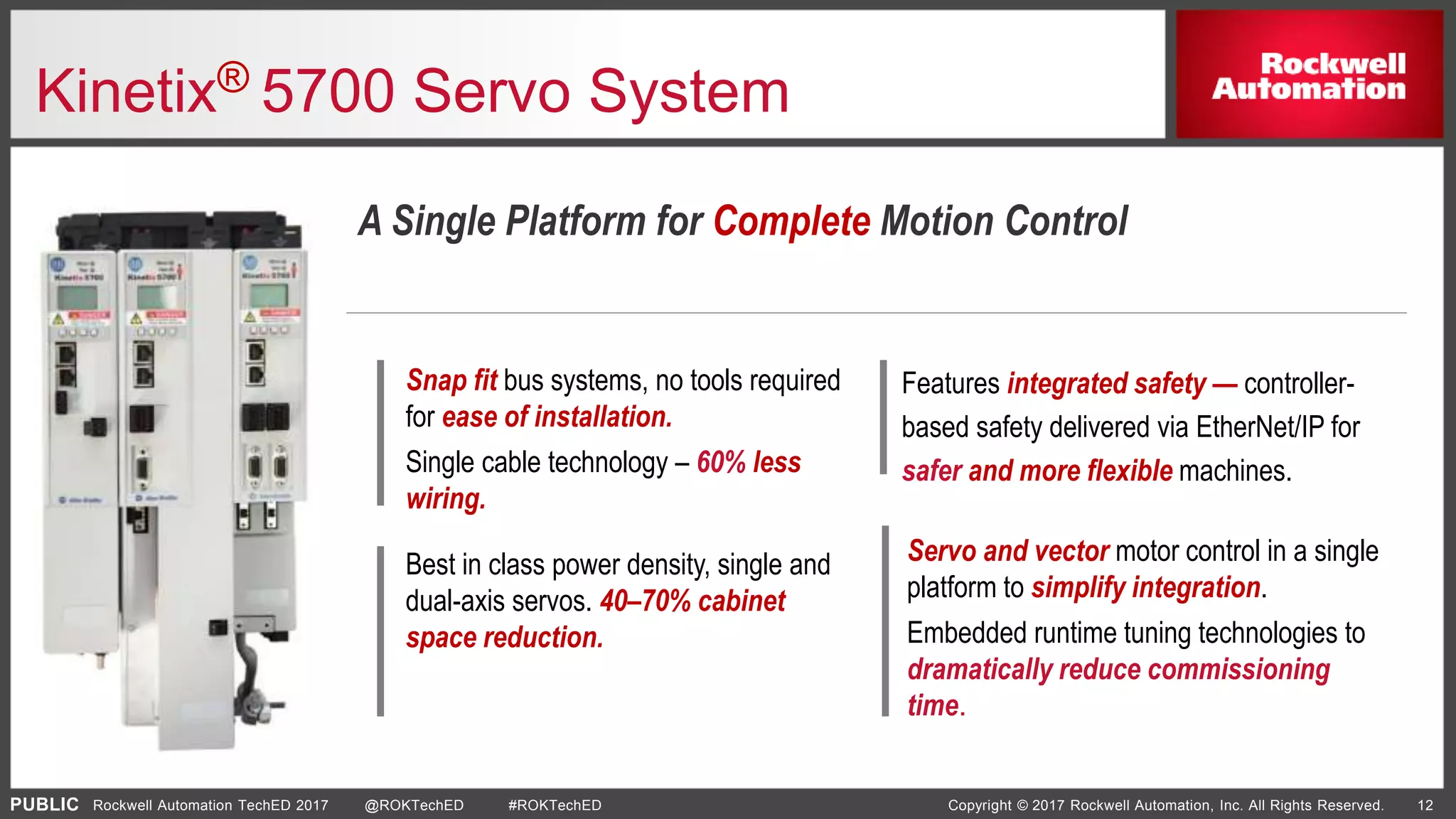

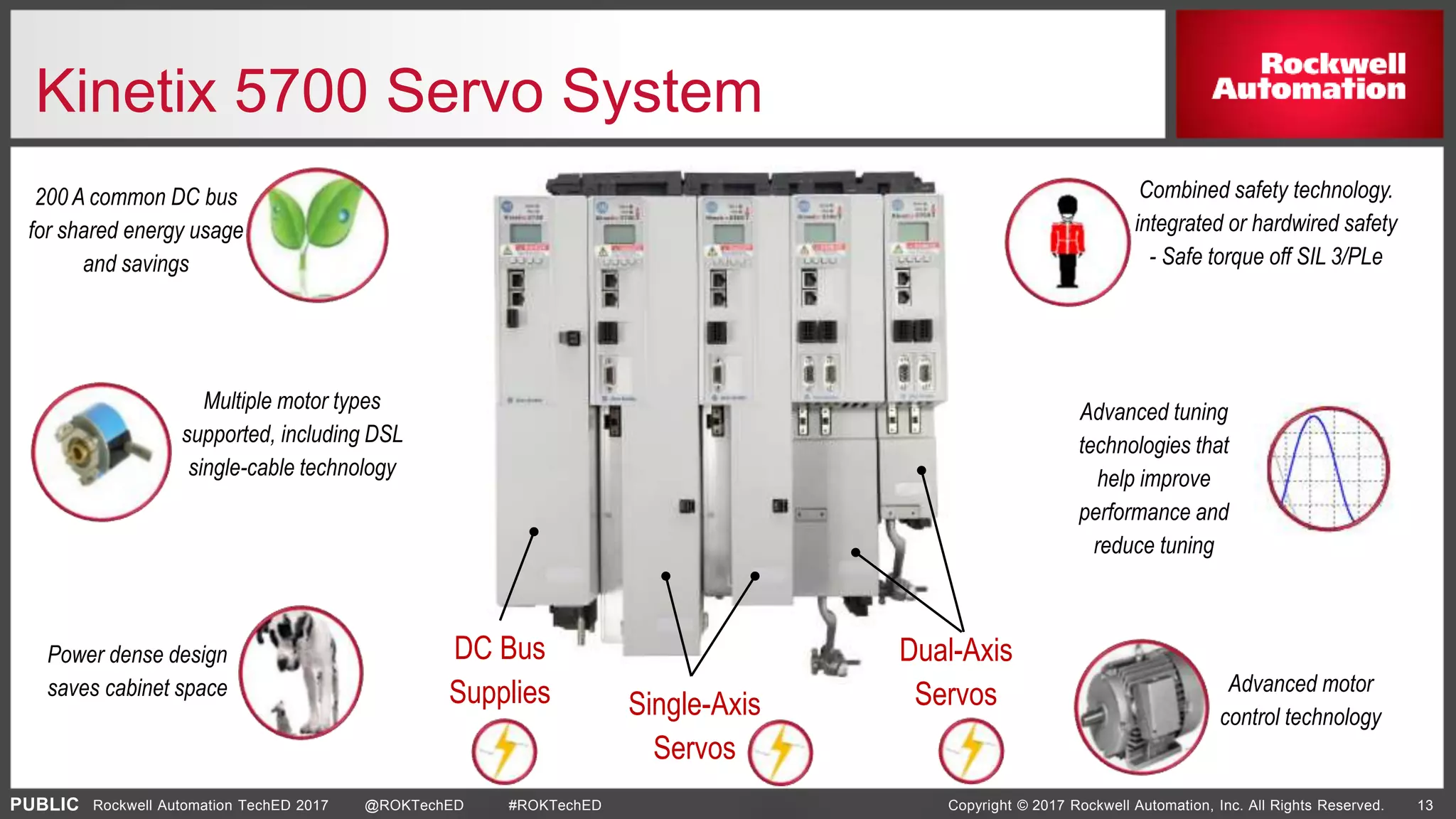

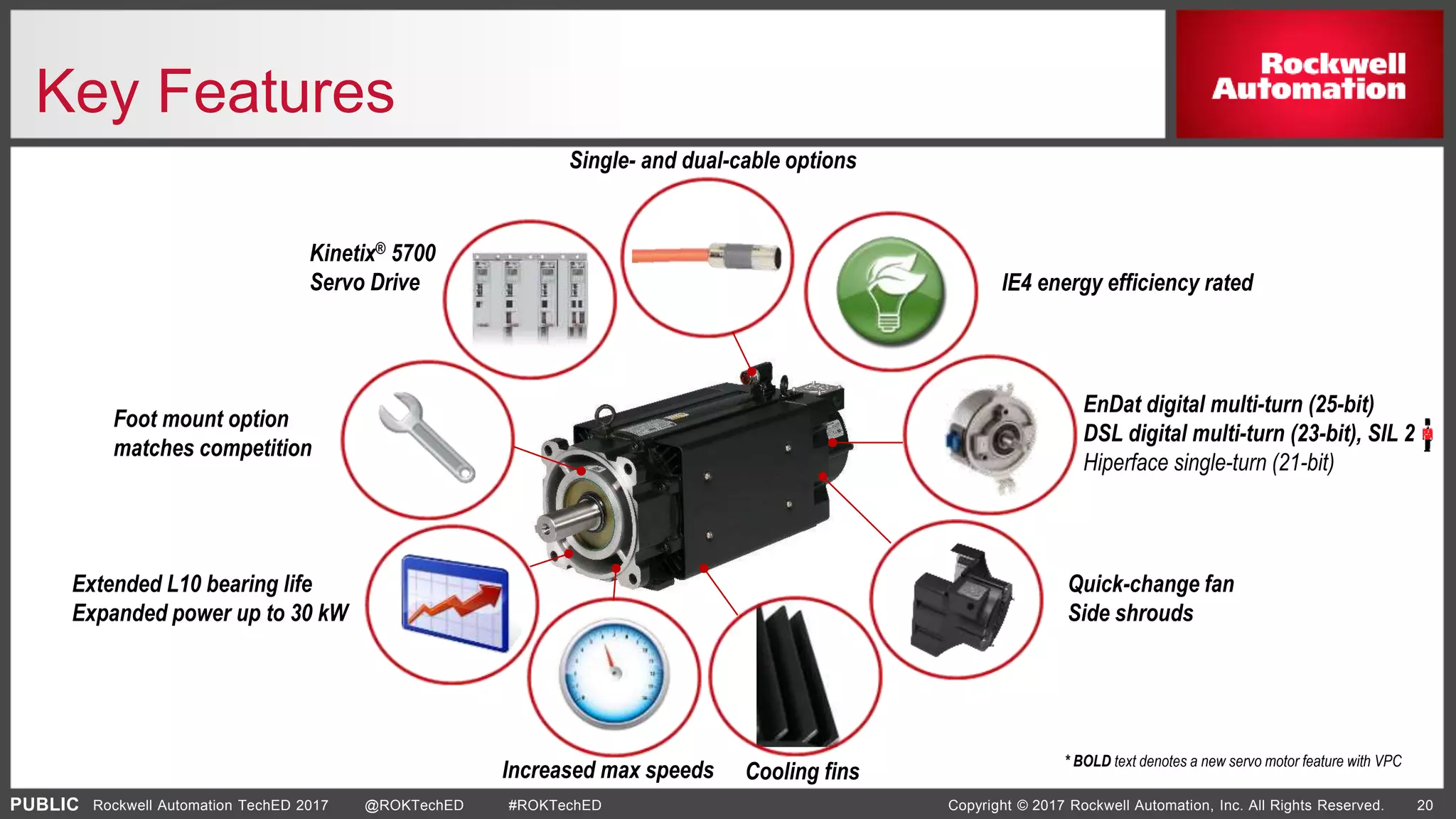

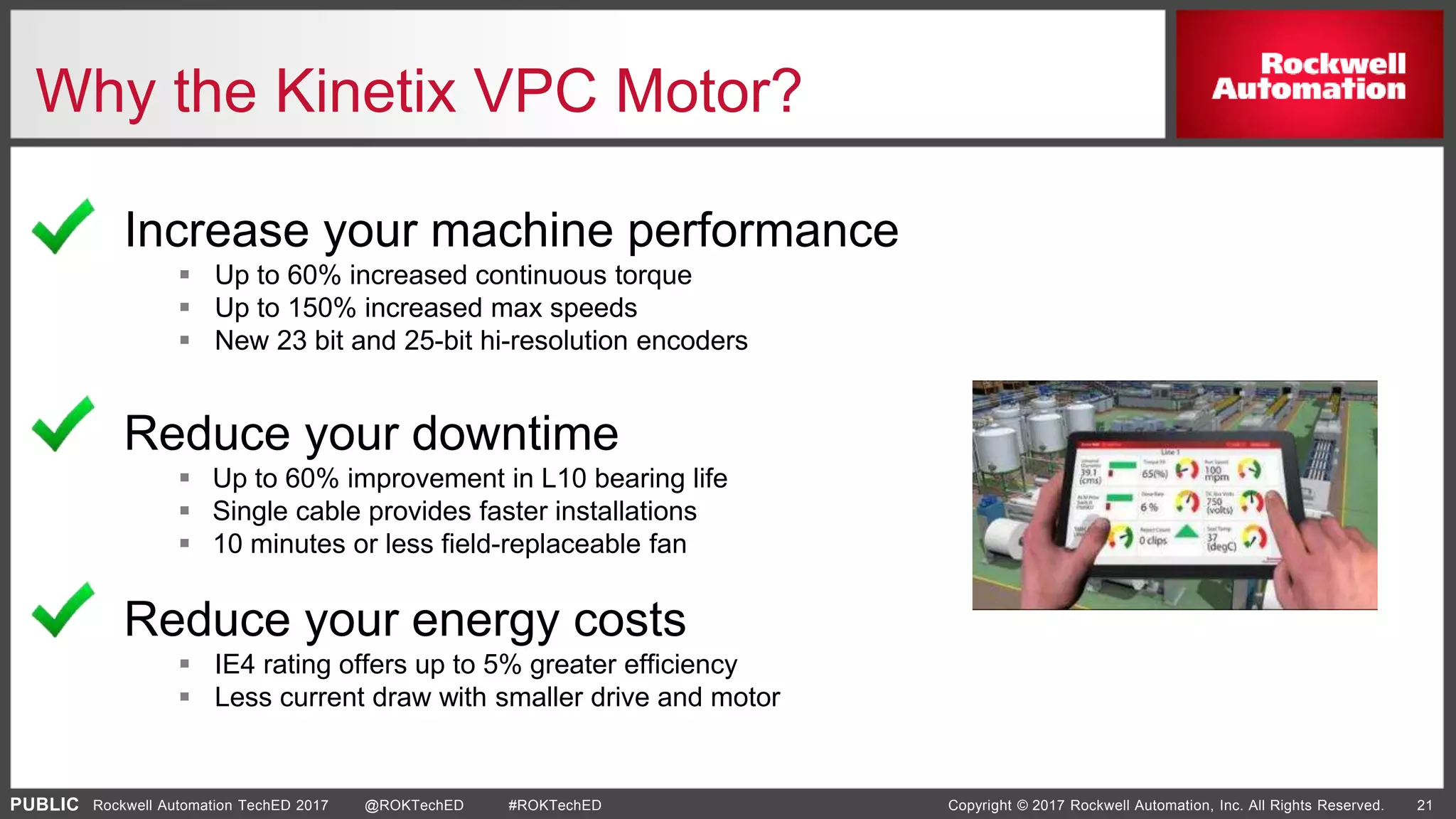

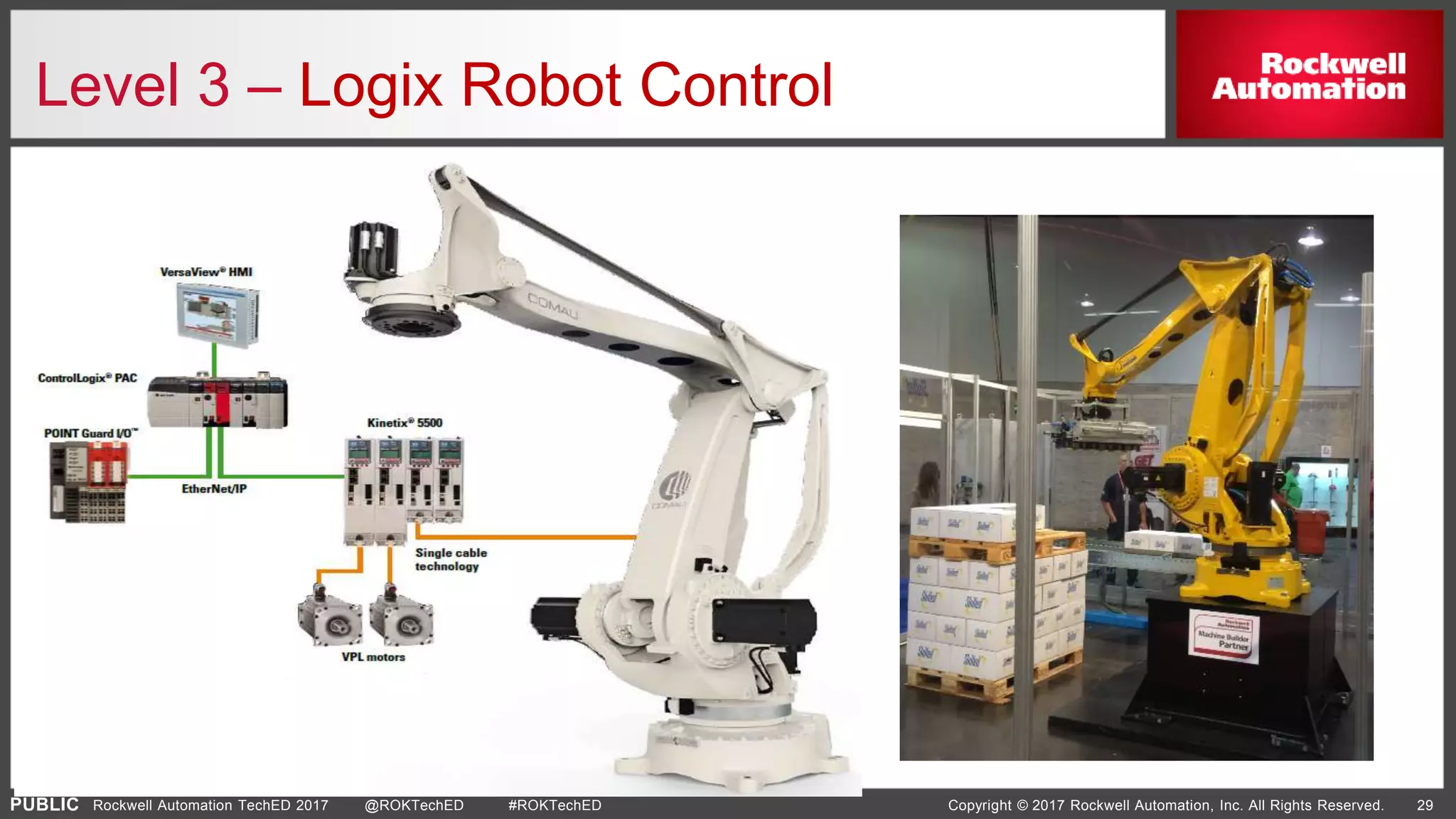

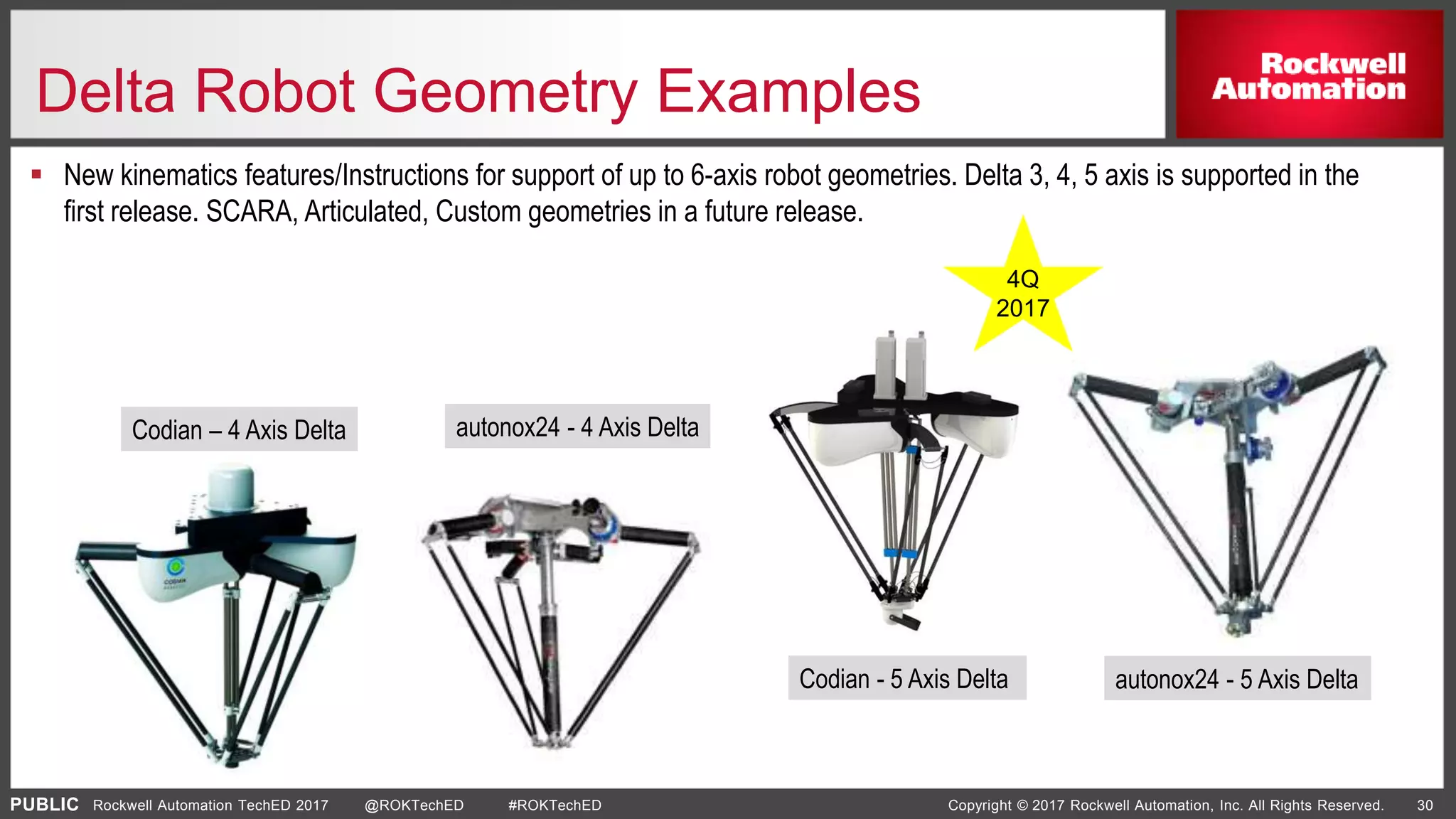

The document provides an overview of Rockwell Automation's integrated motion control solution on EtherNet/IP. It highlights the portfolio of Logix controllers, Kinetix servo drives and motors, safety functionality, and programming capabilities in Studio 5000 Logix Designer. New products include the Kinetix VPC motor, GuardLogix 5580 controller, CompactLogix 5480 controller, and encoder output module. The solution aims to provide scalable, integrated motion control and safety across hardware, software, and programming.

![PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 31Rockwell Automation TechED 2017 @ROKTechED #ROKTechED

MCPM – 6-Axis Interpolation

Coordinated path move of up to 6 axes

Point-to-point (PTP)

Continuous path linear (CP-L)

Structure array profile

Similar to Cam

Time or MDSC mode

Operand Scroll List Or Checkbox Data Type Default Notes

Status List of {status bits} DINT 0 This will be hidden and not used in Release 1-Bit pattern

containing status of MCPM array element

Interpolation Type List of {Point to Point(0)

Continuous Path Linear(1)}

DINT 0 PTP – Point to Point

CP-L – Continuous Path Linear

Position [X, Y, Z, Rx, Ry, Rz] List of {constant or variable} REAL[9] 1 0 Coordination Units

Robot Configuration List of { Bit values:

Bit0 – Robot Configuration Change(1)/Same(0)

Bit1 – Lefty(1)/Righty(0)

Bit2 – Above(1)/Below(0)

Bit3 – Flip(1/No flip(0)}

DINT 0 Bit 0 – Always zero for Delta

Bit 1 – Don’t care for Delta

Bit 2 – Don’t care for Articulated Dependent, Delta and

SCARA

Bit 3 – Don’t care for Articulated Dependent, Delta and

SCARA

Turns Counters List of {variable} INT 16 0 J1, J4, J6 Joint axes Turns counters. Each integer is a

signed value.

Move Type List of {absolute(0),Incremental(1) bits} DINT 0

Termination Type List of {Actual Tolerance(0), No Settle(1),Command Tolerance(6)} DINT 0

Command Tolerance Linear List of {constant or variable} Real TBD not 0 Used for Linear axes only

Coordination Units Linear

Operand Scroll List or Checkbox Data

Type

Default Notes

Units Mode List of{0 = % of Maximum

1 = Coord Units (per)

2 = Time Based (future)}

DINT 0 Time Based not supported in

Release 1

Time Units List of{0 = Seconds

1 = Master Units}

DINT 0 Not use for %Maximum

Applicable to speed and

acc/dec only.

Profile List of{0= Trapezoidal

1= S-Curve}

DINT 0 *1

Speed List of {Constant or Value} Real 0 *1

% of Maximum -or-

Coordination Units/Time Unit

-or- Time Units

Acceleration List of {Constant or Value} Real 0 *1

% of Maximum -or-

Coordination Units/Time

Unit2

-or- Time Units

Deceleration List of {Constant or Value} Real 0 *1

% of Maximum -or-

Coordination Units/Time

Unit2

-or- Time Units

Acceleration

Jerk

List of {Constant or Value} Real 0 Always % Time

For all axes always

Deceleration

Jerk

List of {Constant or Value} Real 0 Always % Time

For all axes always

Orientation

Speed

List of {Constant or Value } Real 0 Degrees/Time Unit

Only used if Units Mode is

Coordination Units

Orientation

Acceleration

List of {Constant or Value } Real 0 Degrees/Time Unit2

Only used if Units Mode is

Coordination Units

Orientation

Deceleration

List of {Constant or Value } Real 0 Degrees/Time Unit2

Only used if Units Mode is

Coordination Units

4Q

2017](https://image.slidesharecdn.com/rockwellautomationteched2017-cl14-integratedmotiononethernetipsolutionoverview-170619153723/75/Integrated-Motion-on-EtherNet-IP-Solution-Overview-31-2048.jpg)