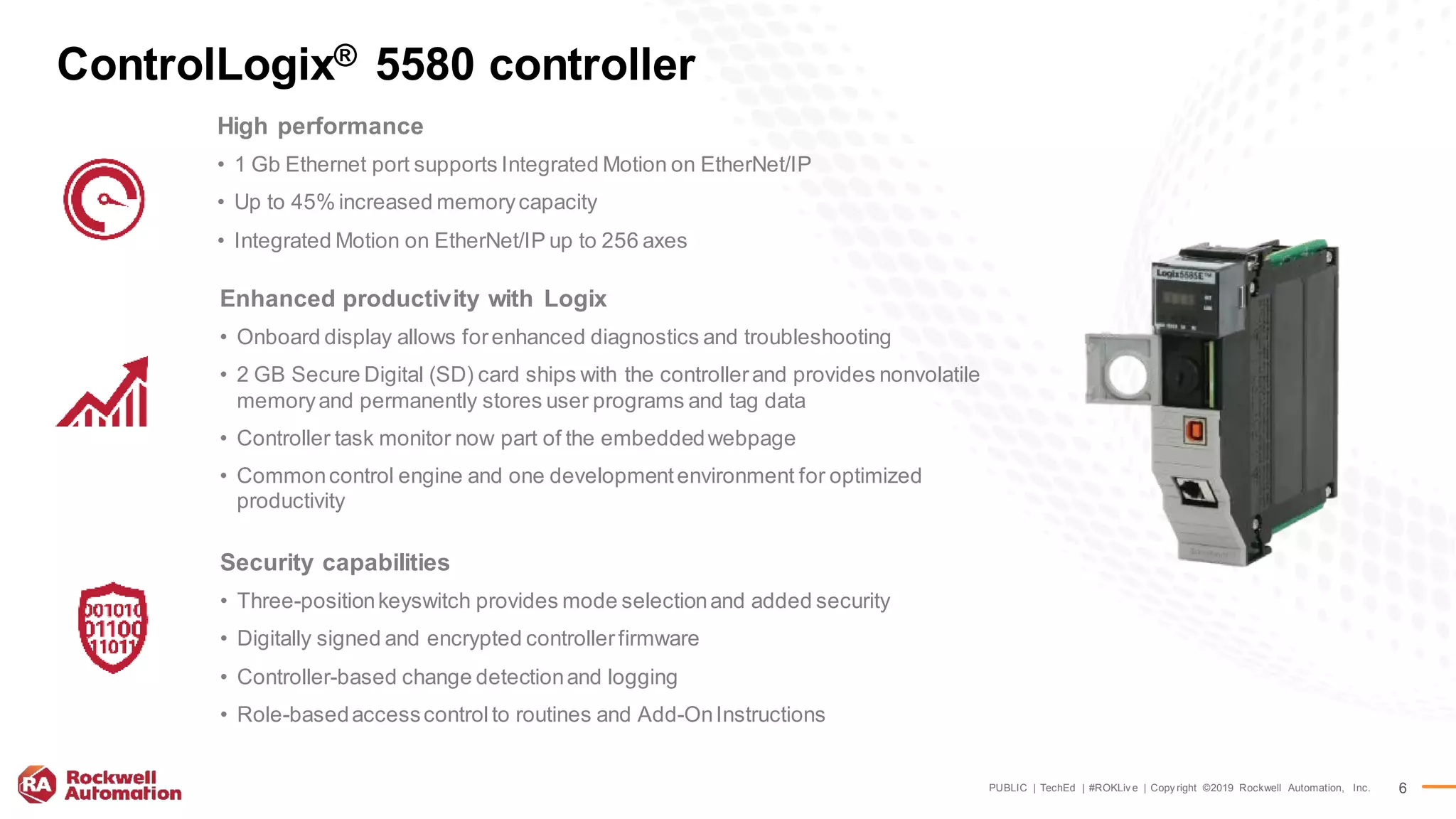

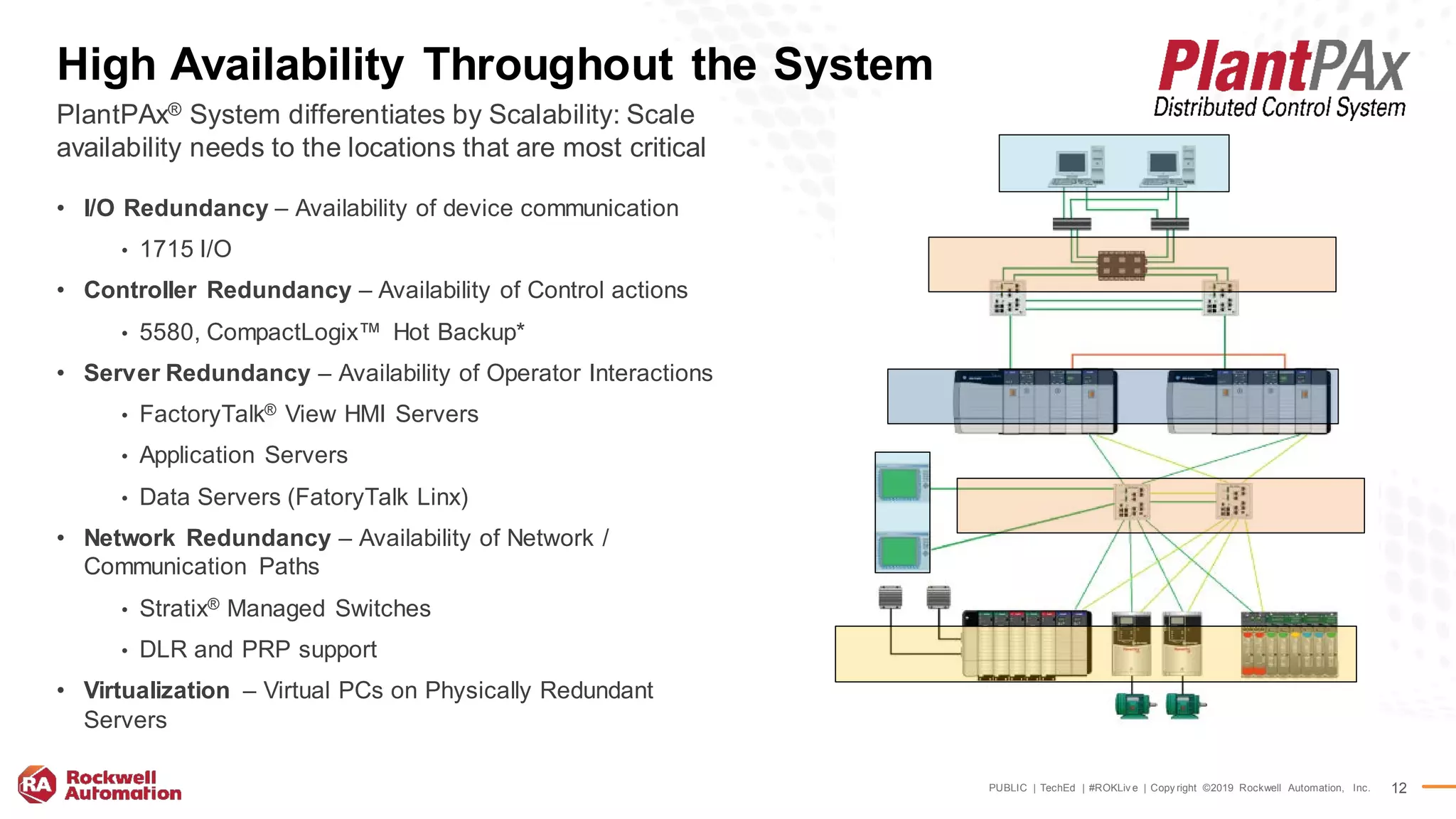

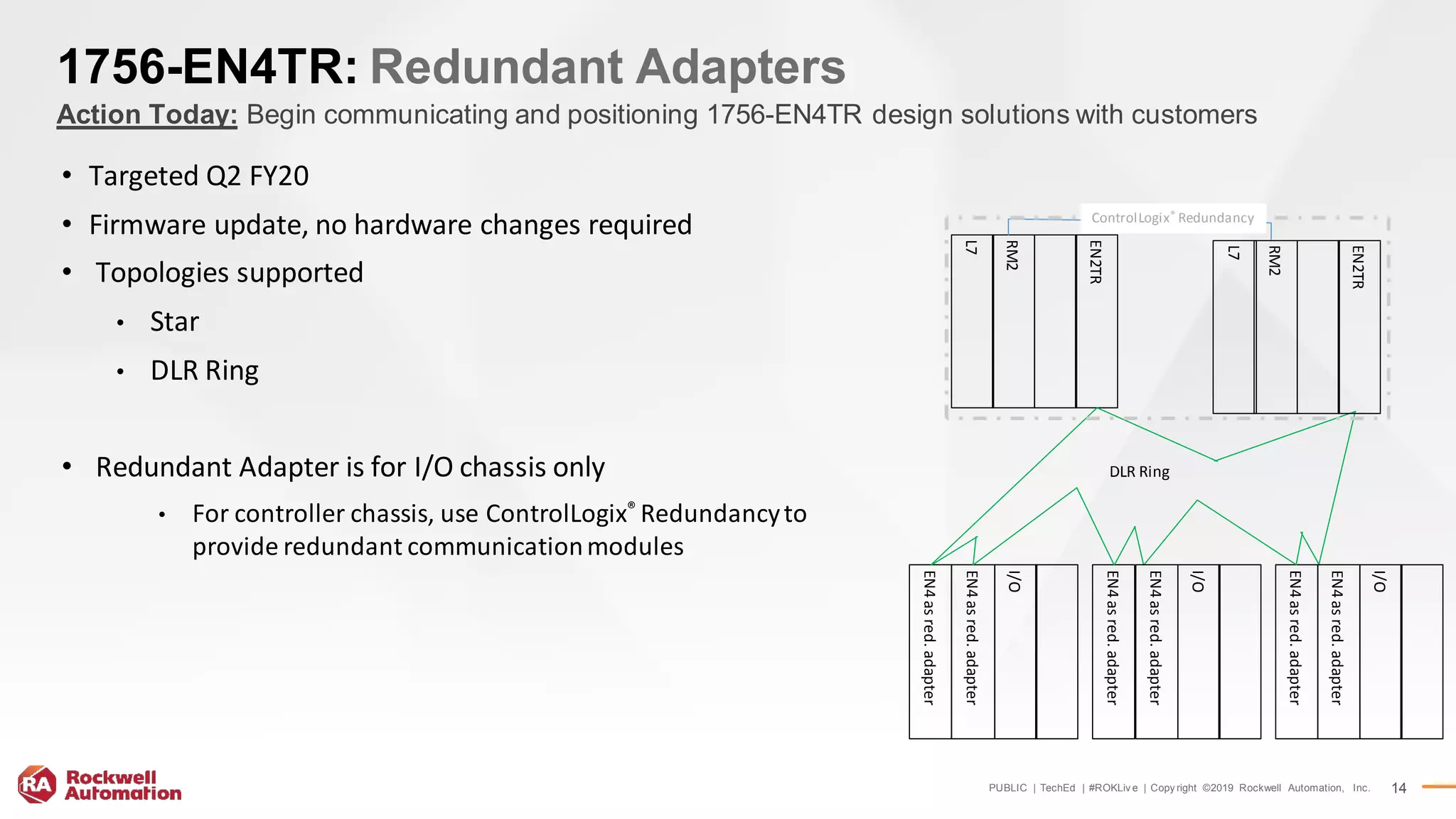

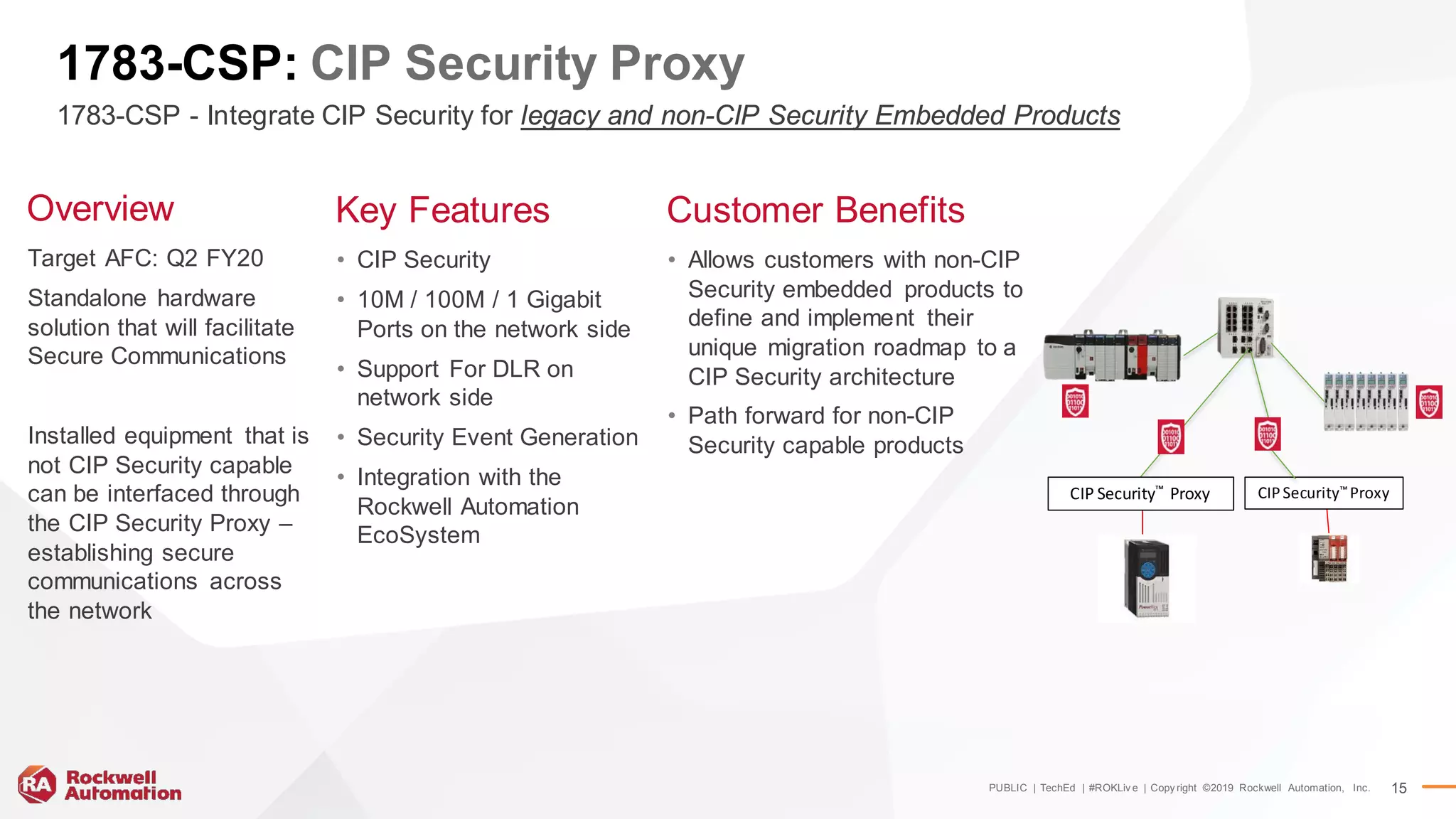

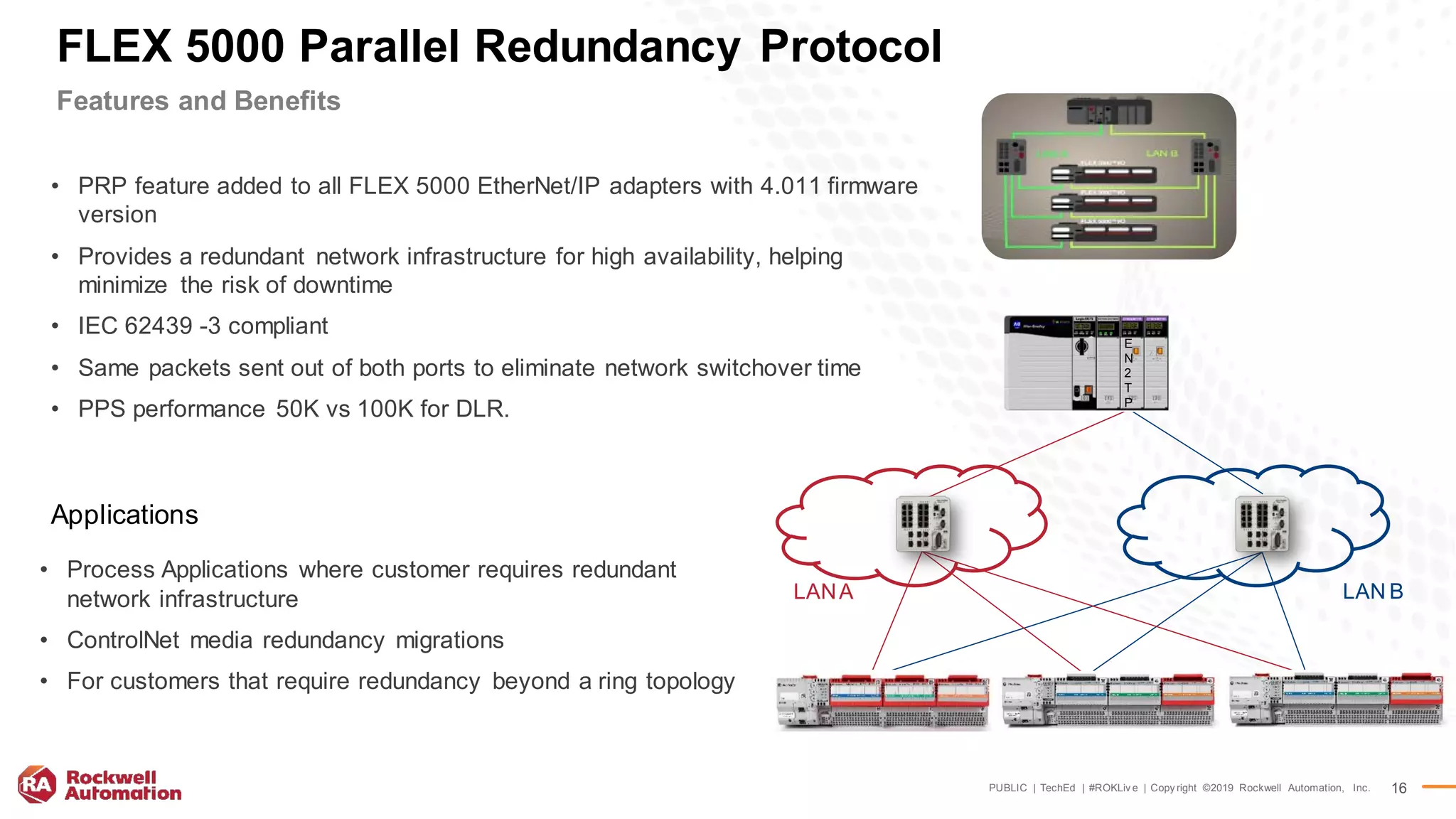

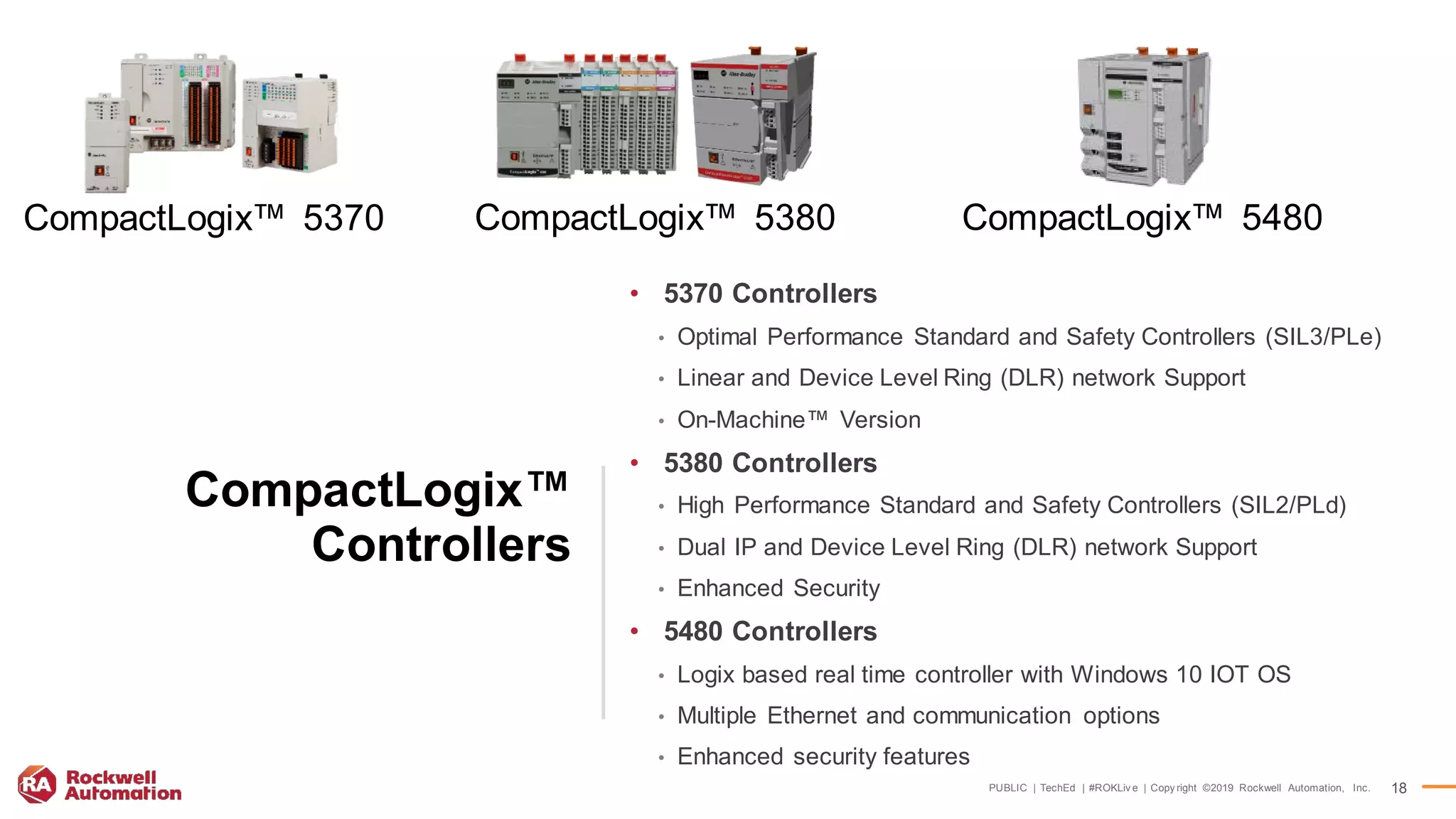

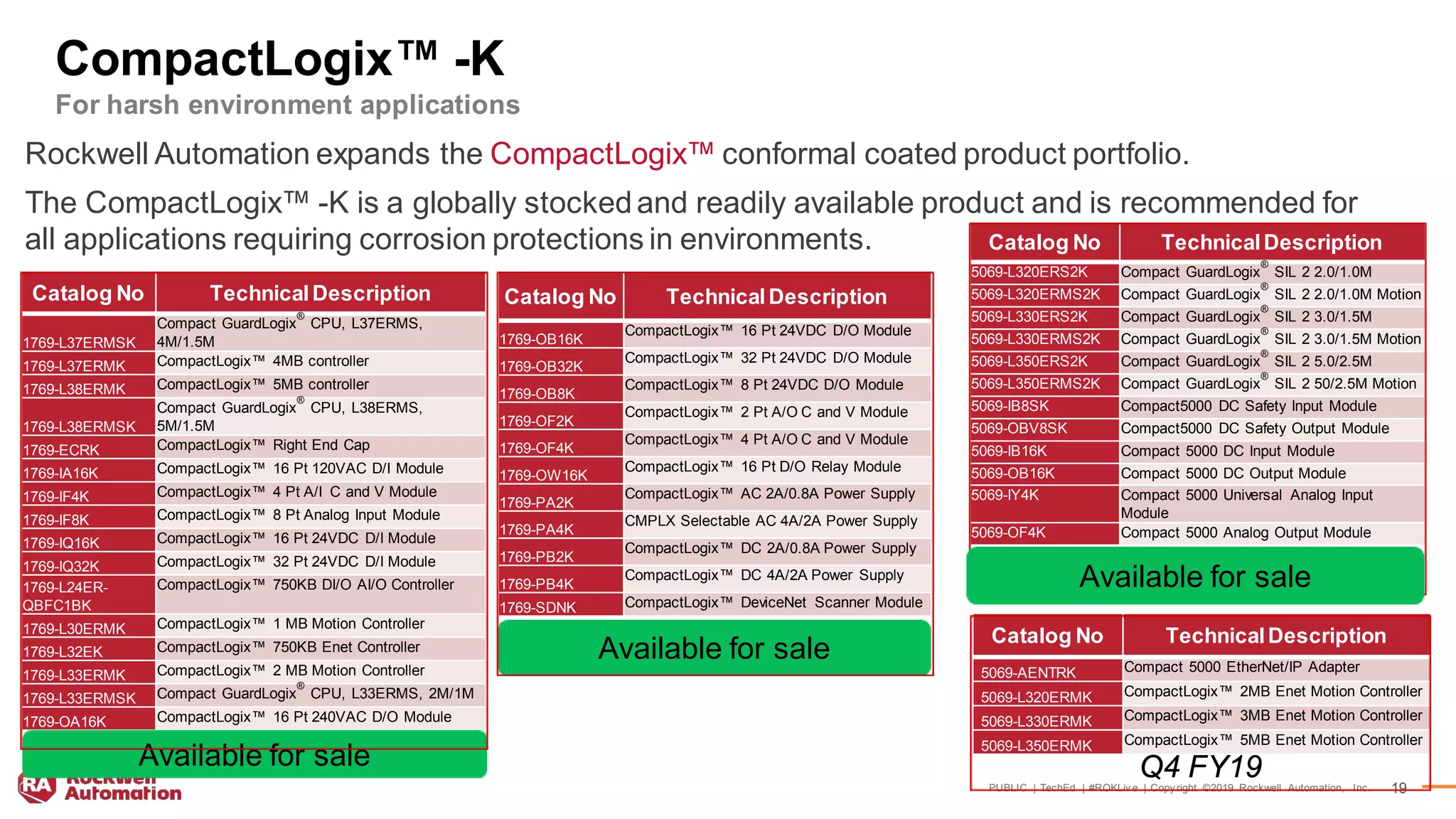

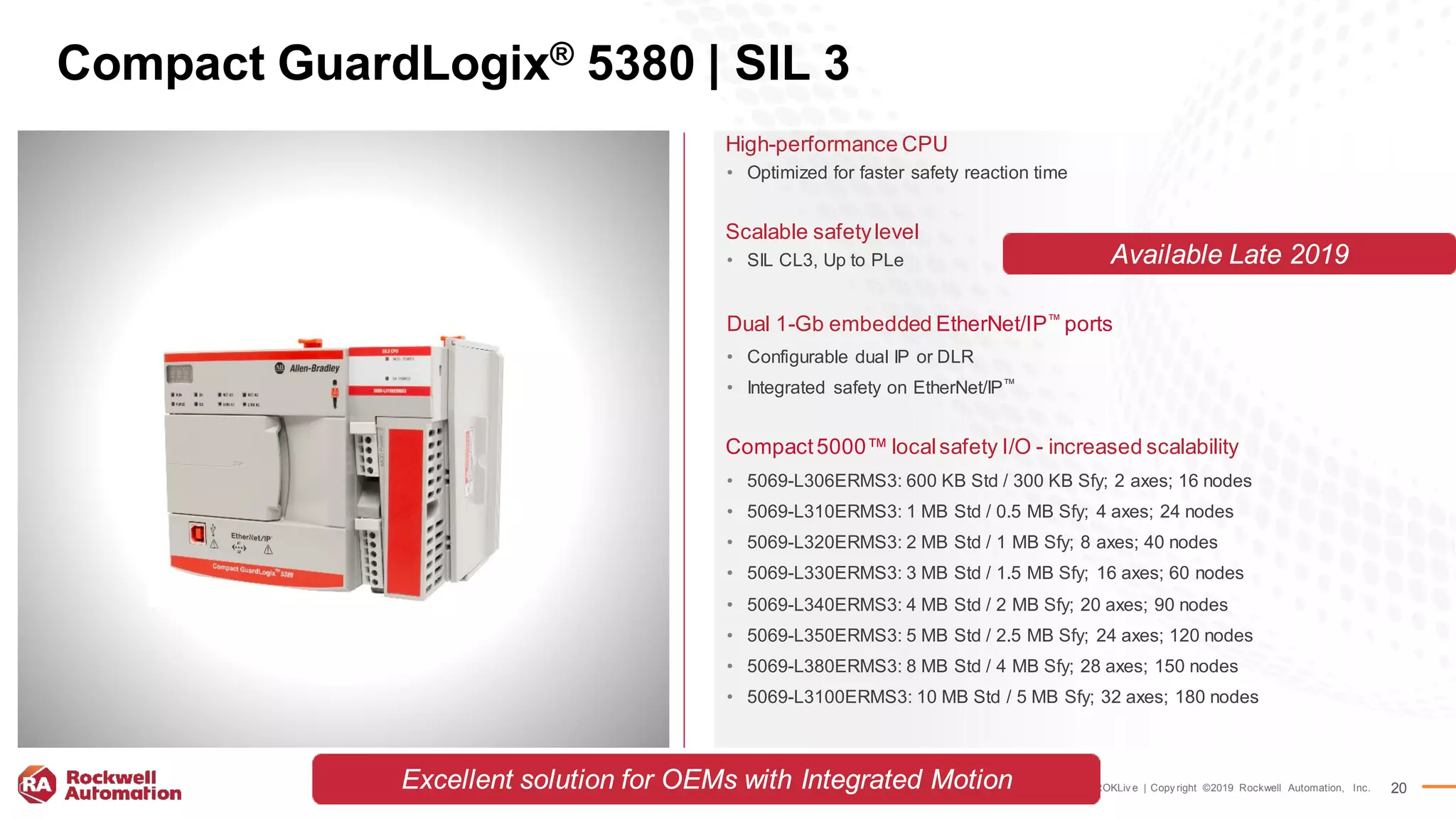

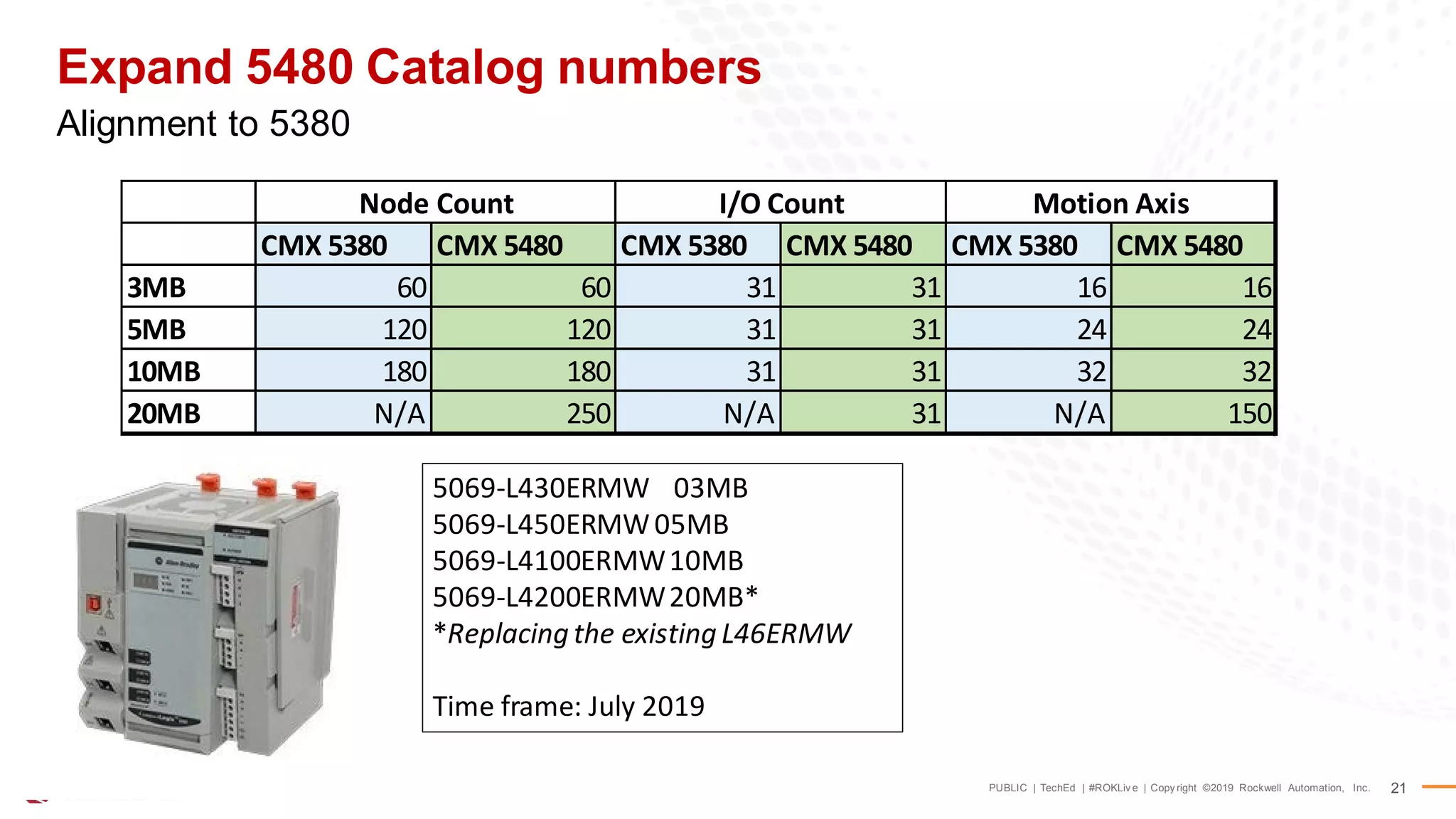

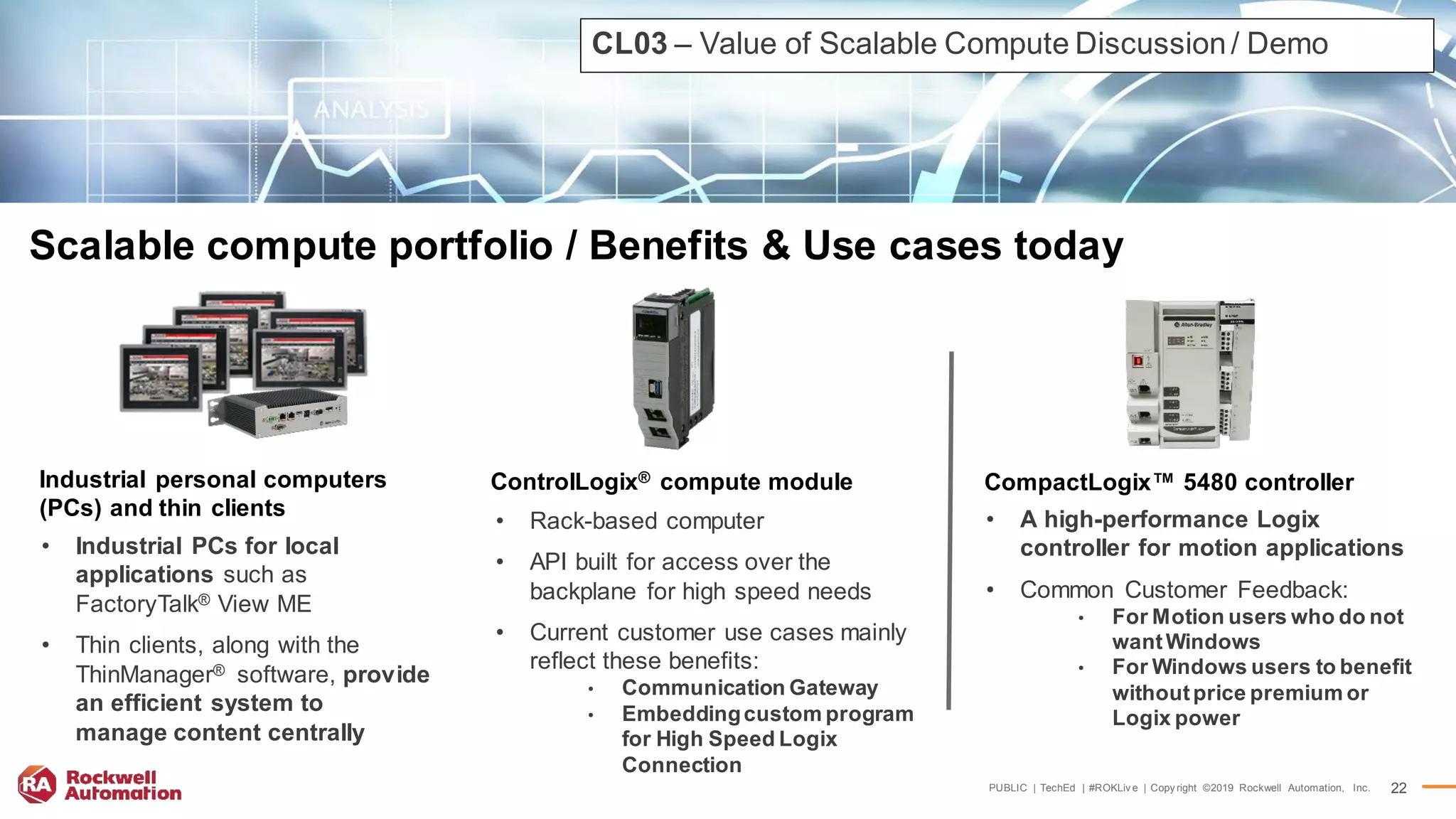

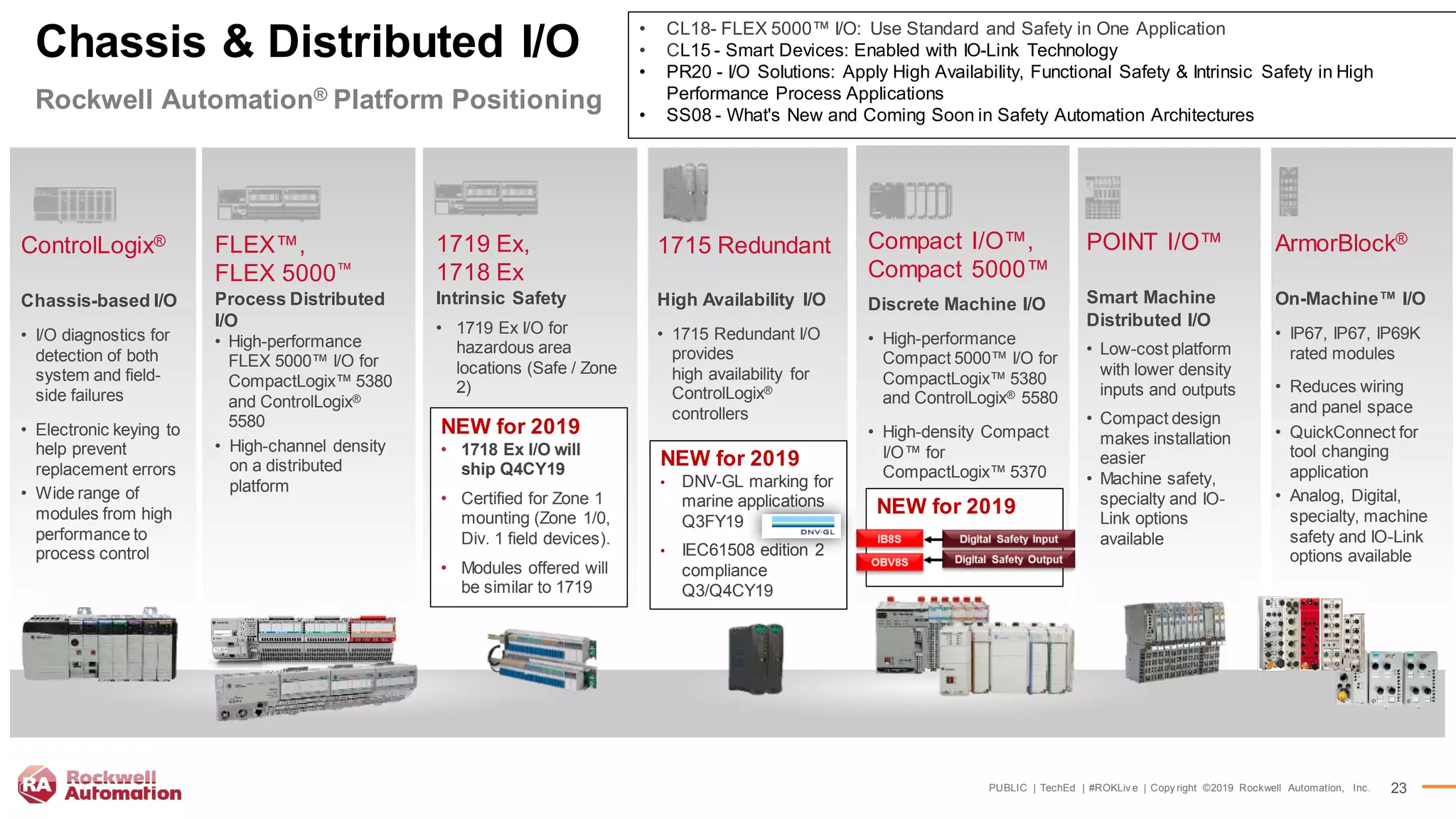

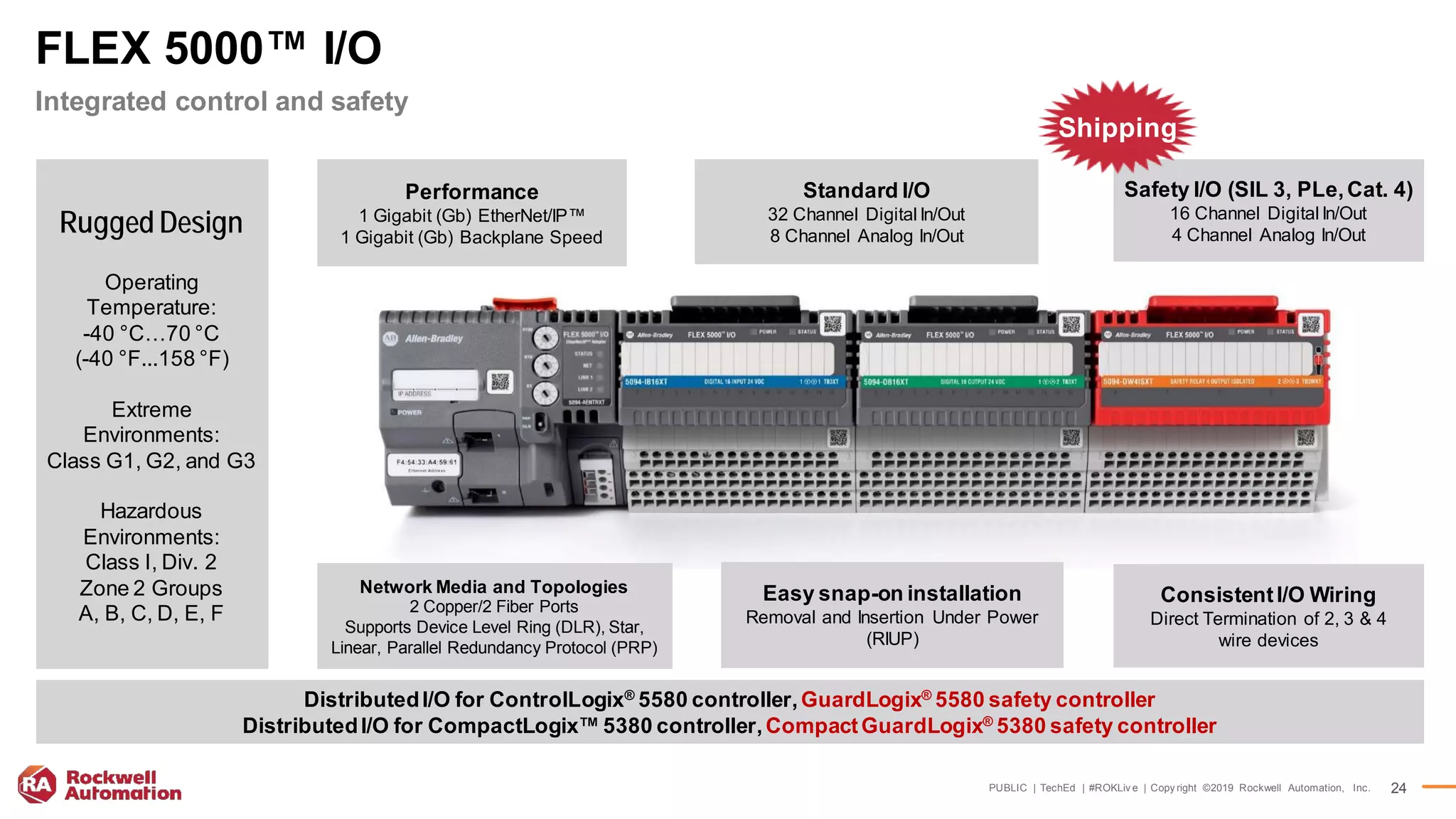

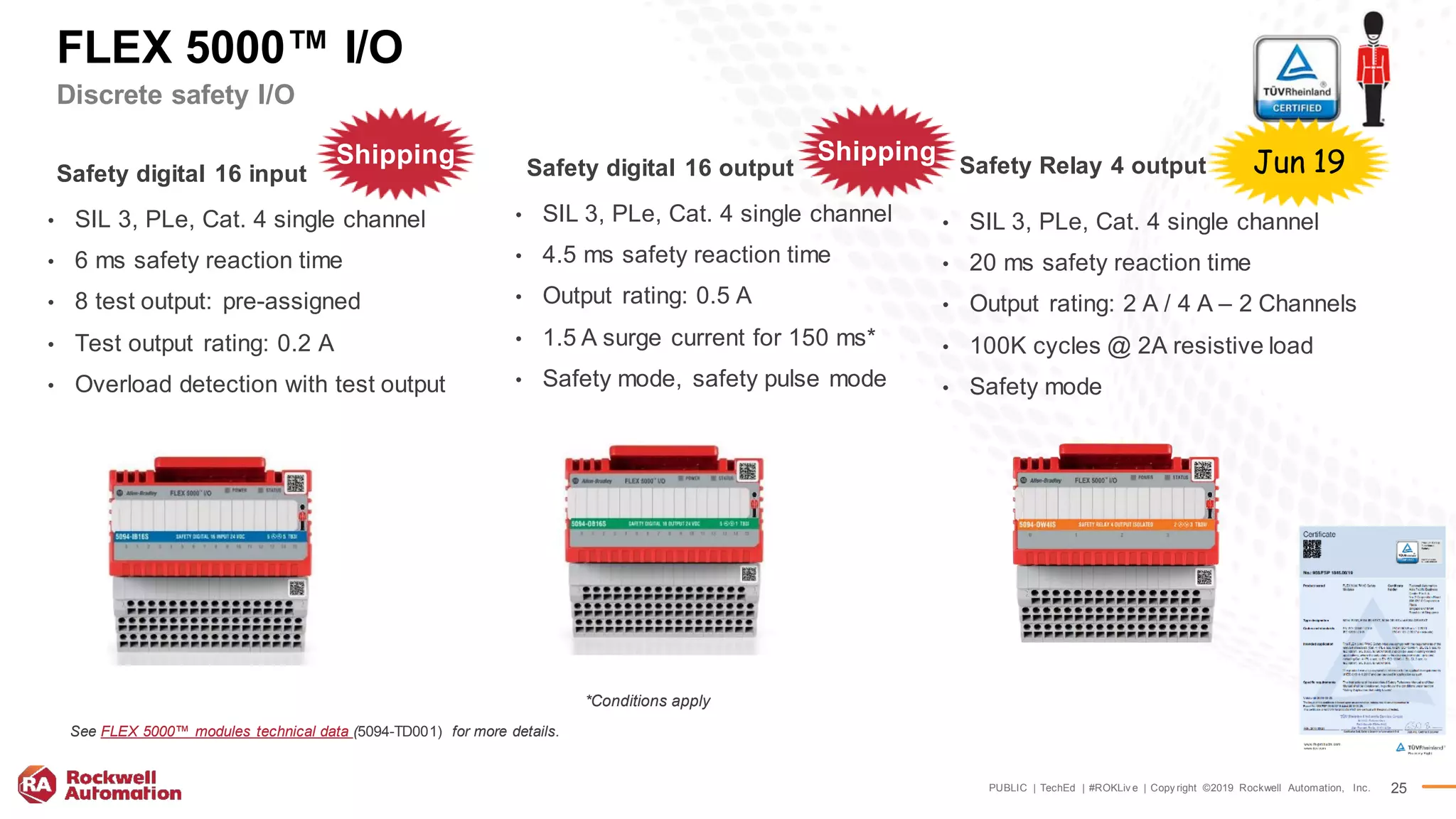

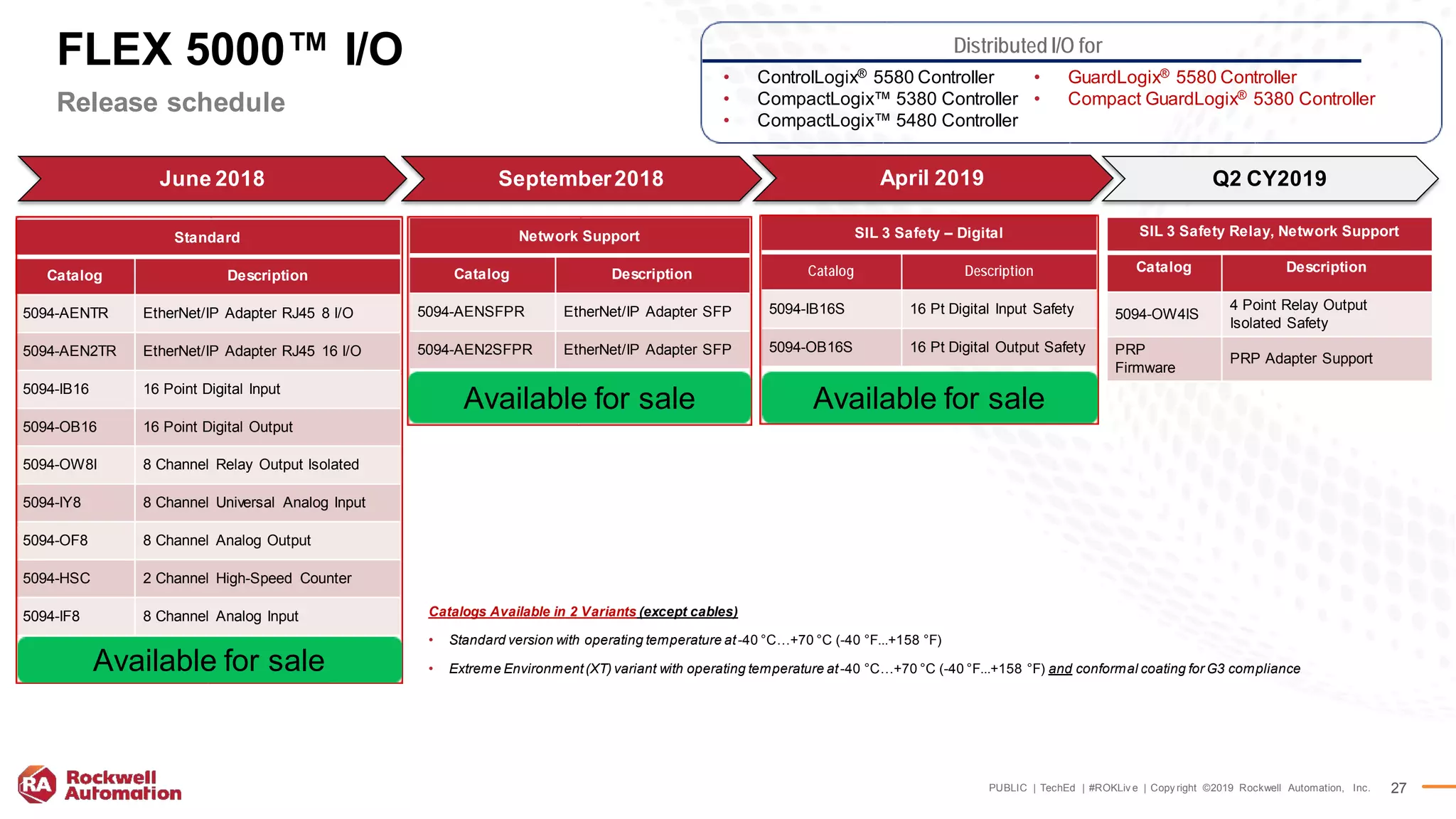

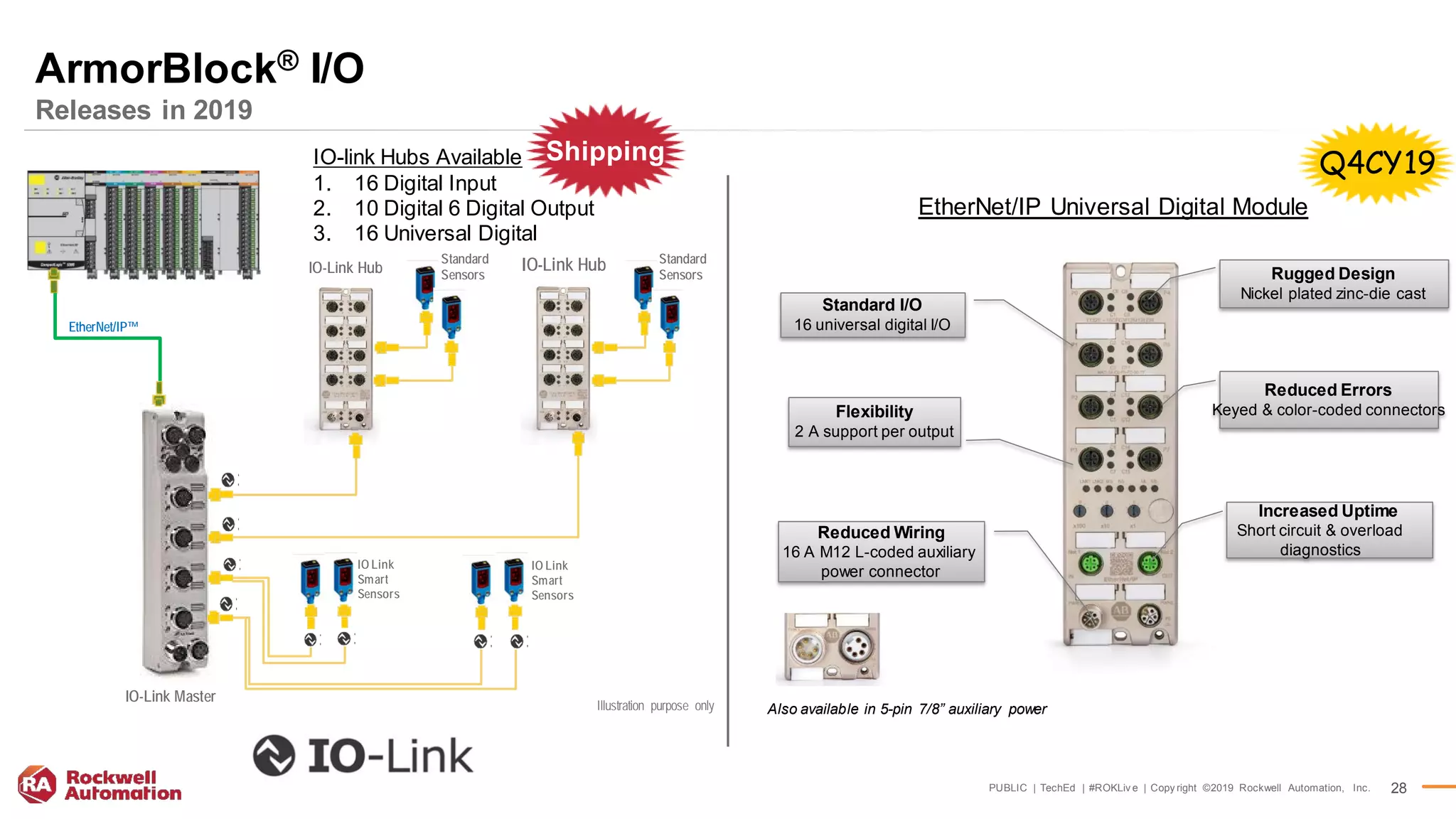

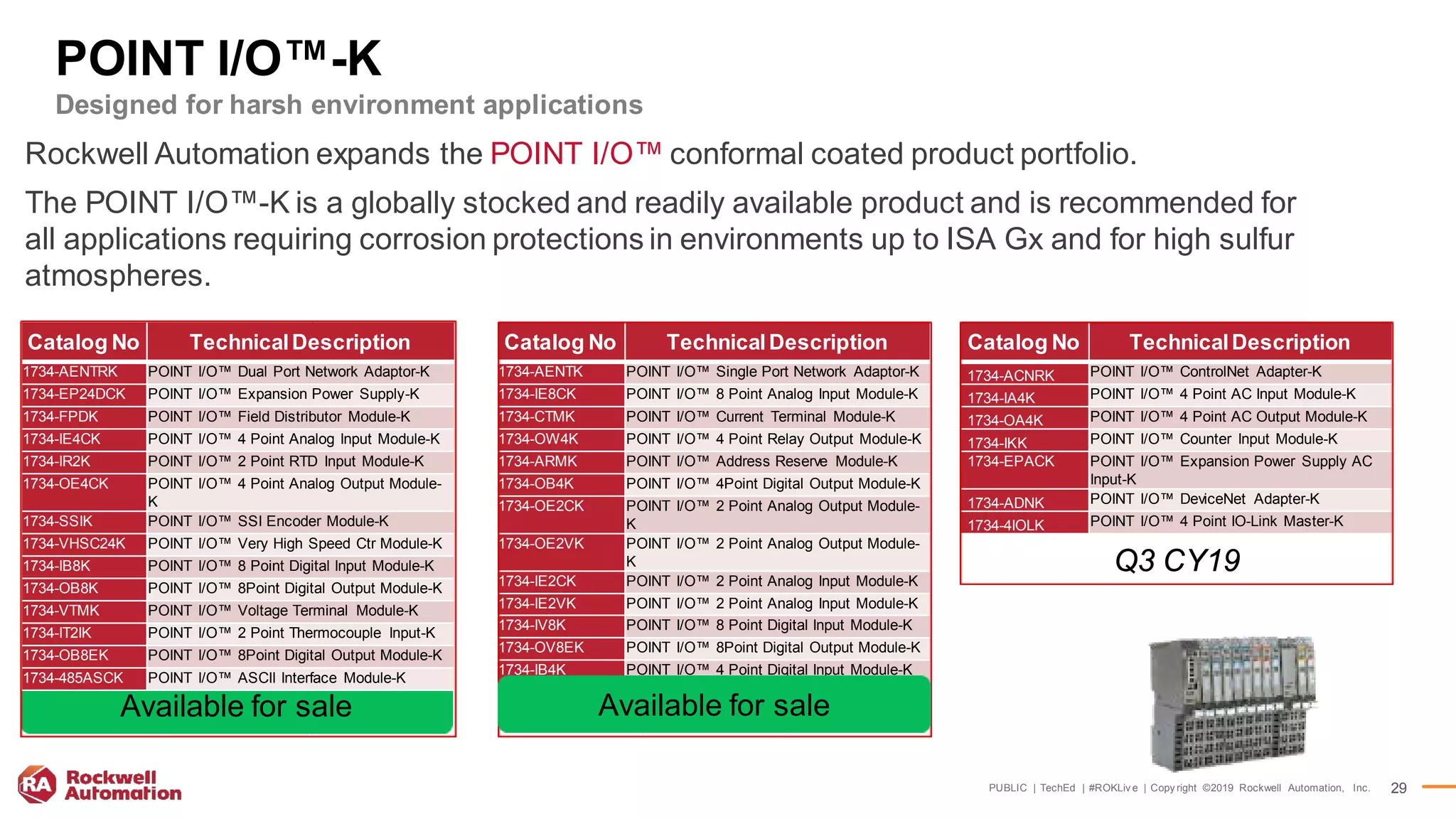

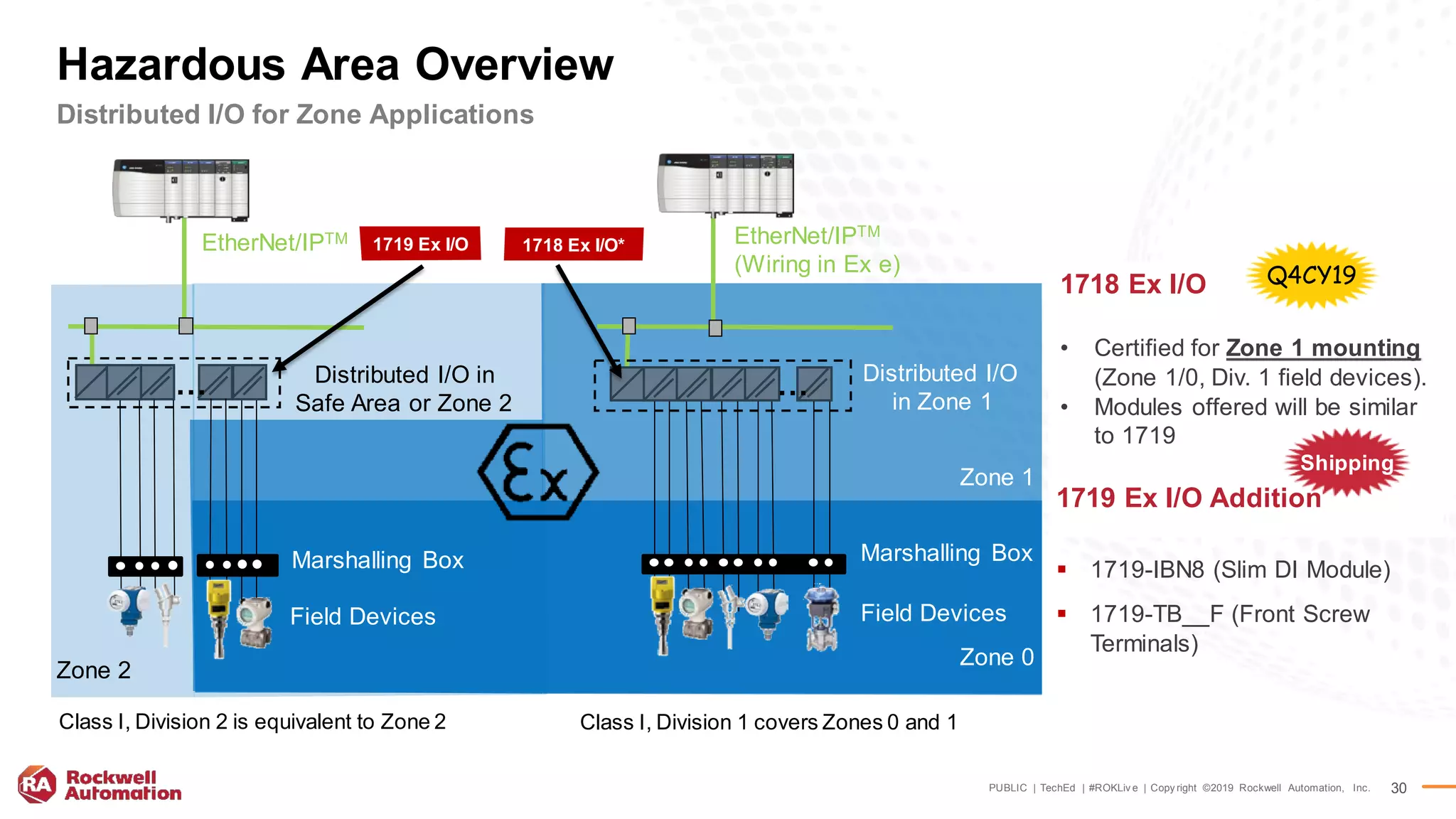

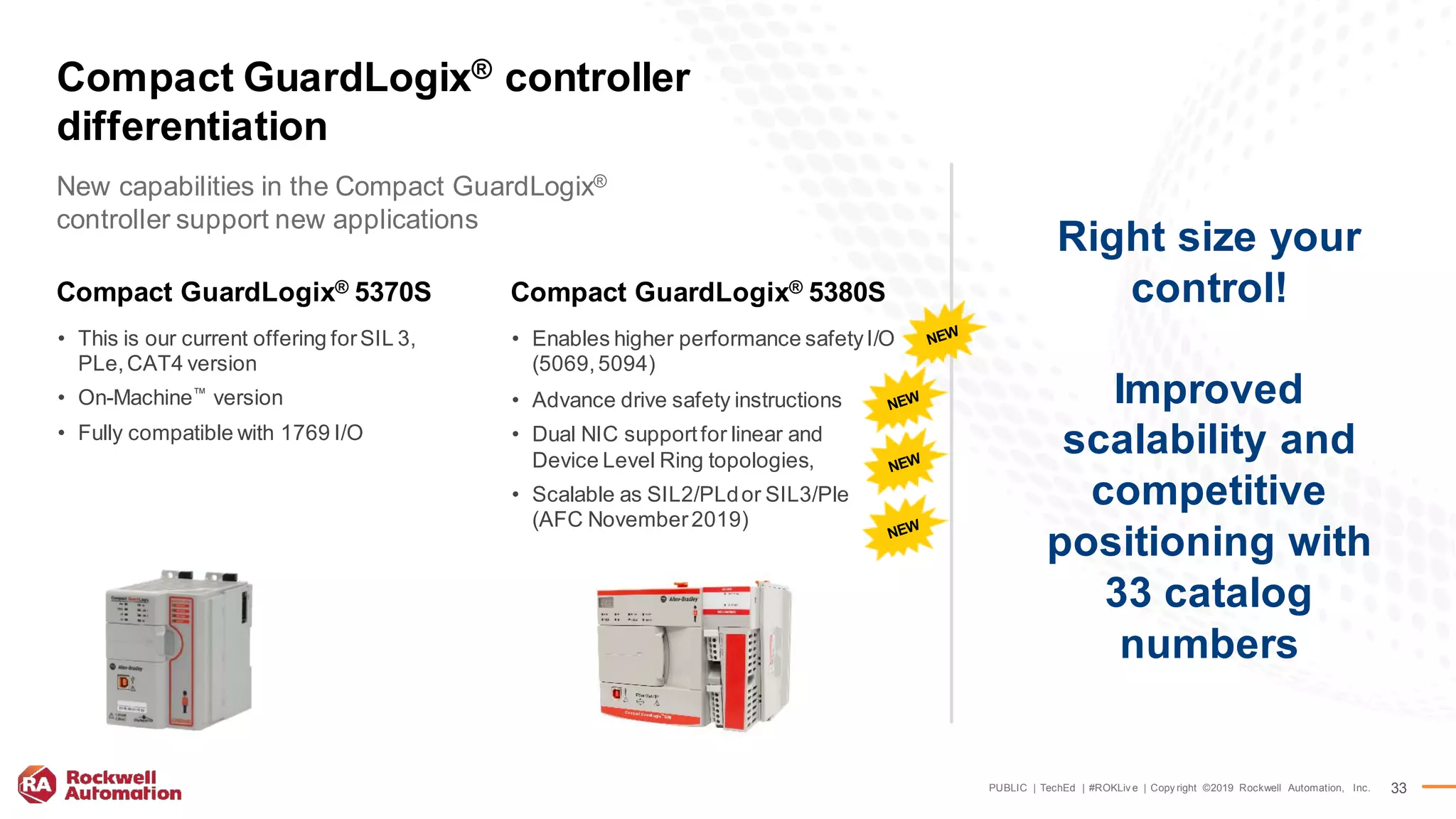

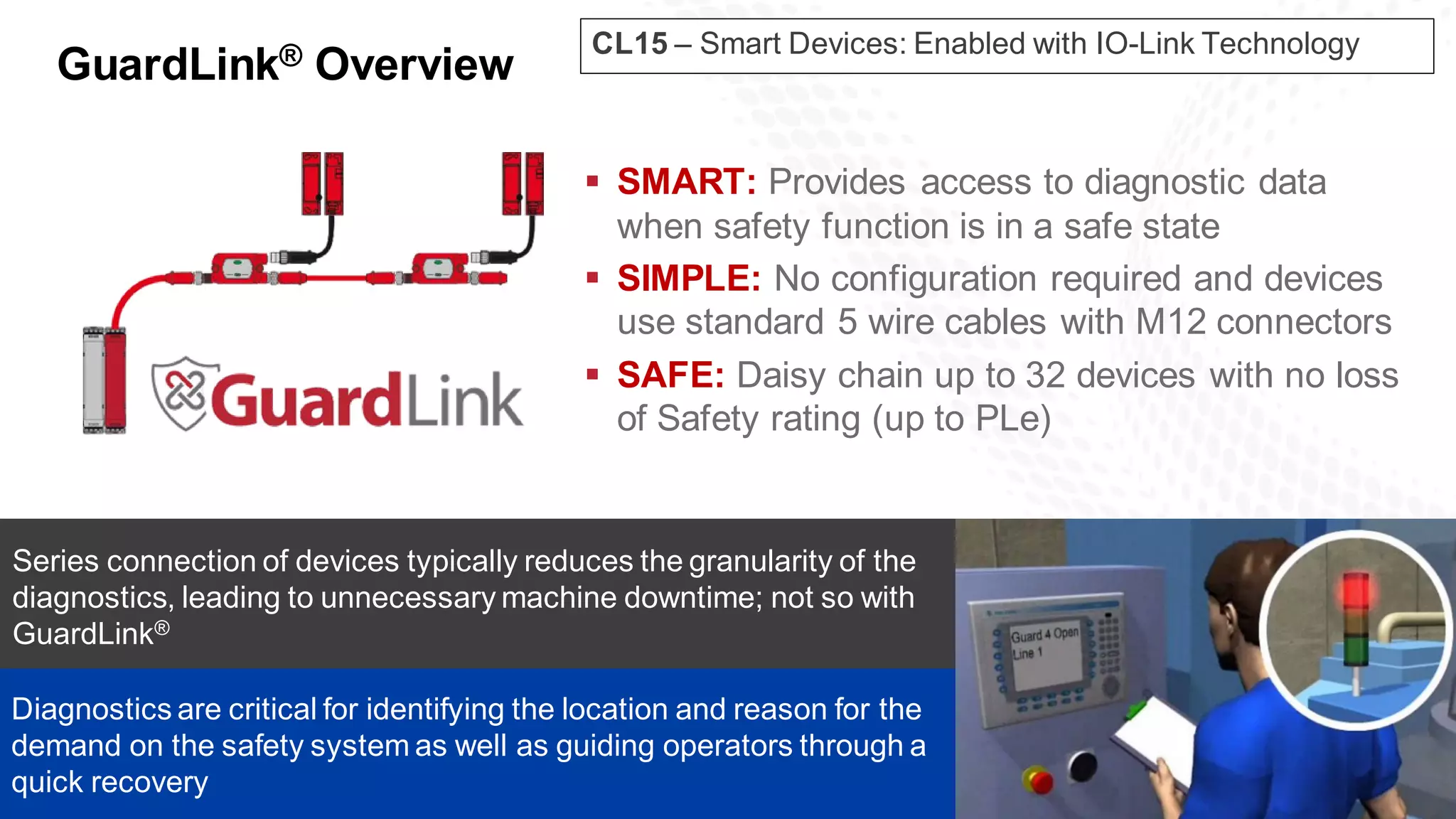

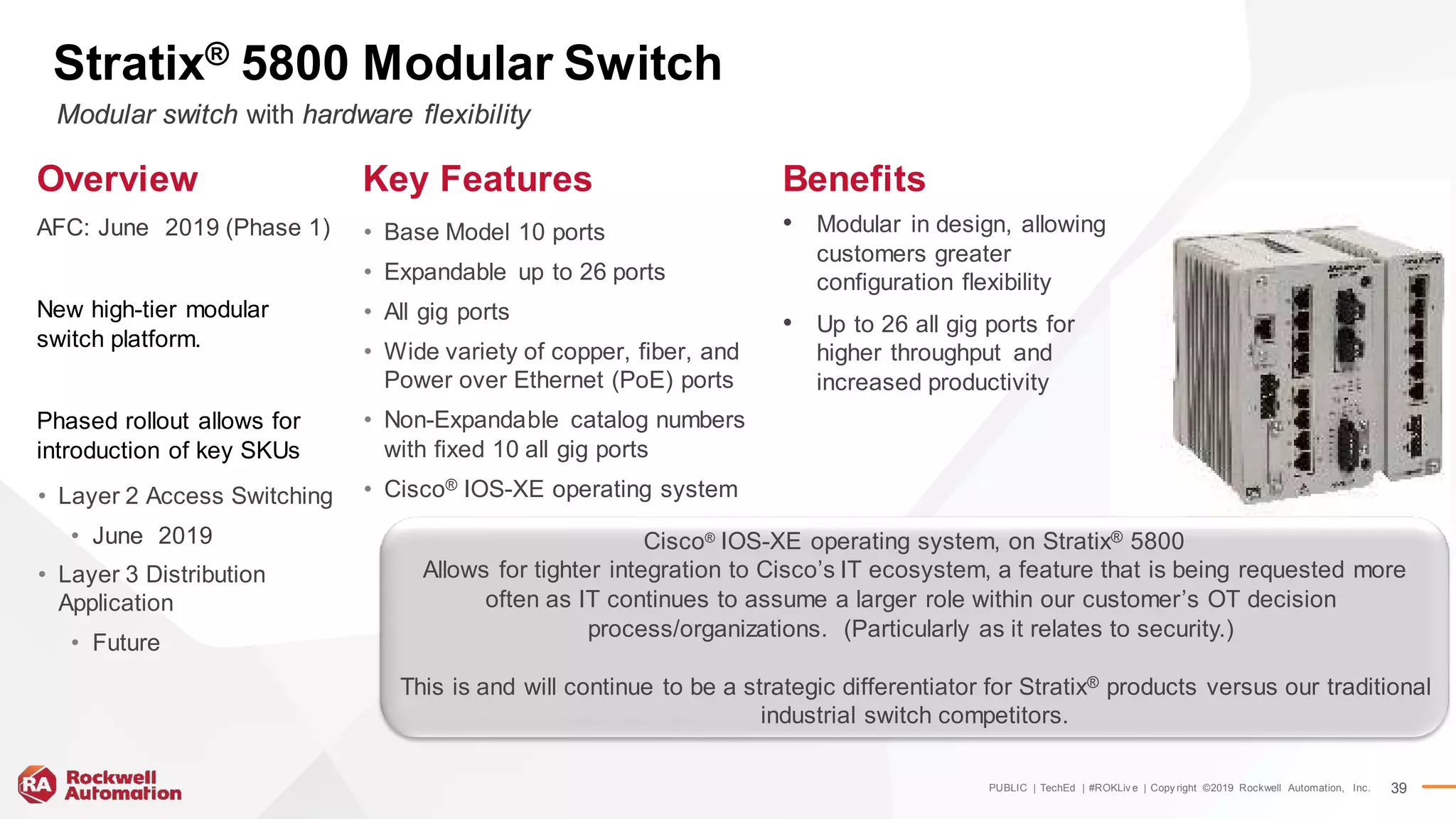

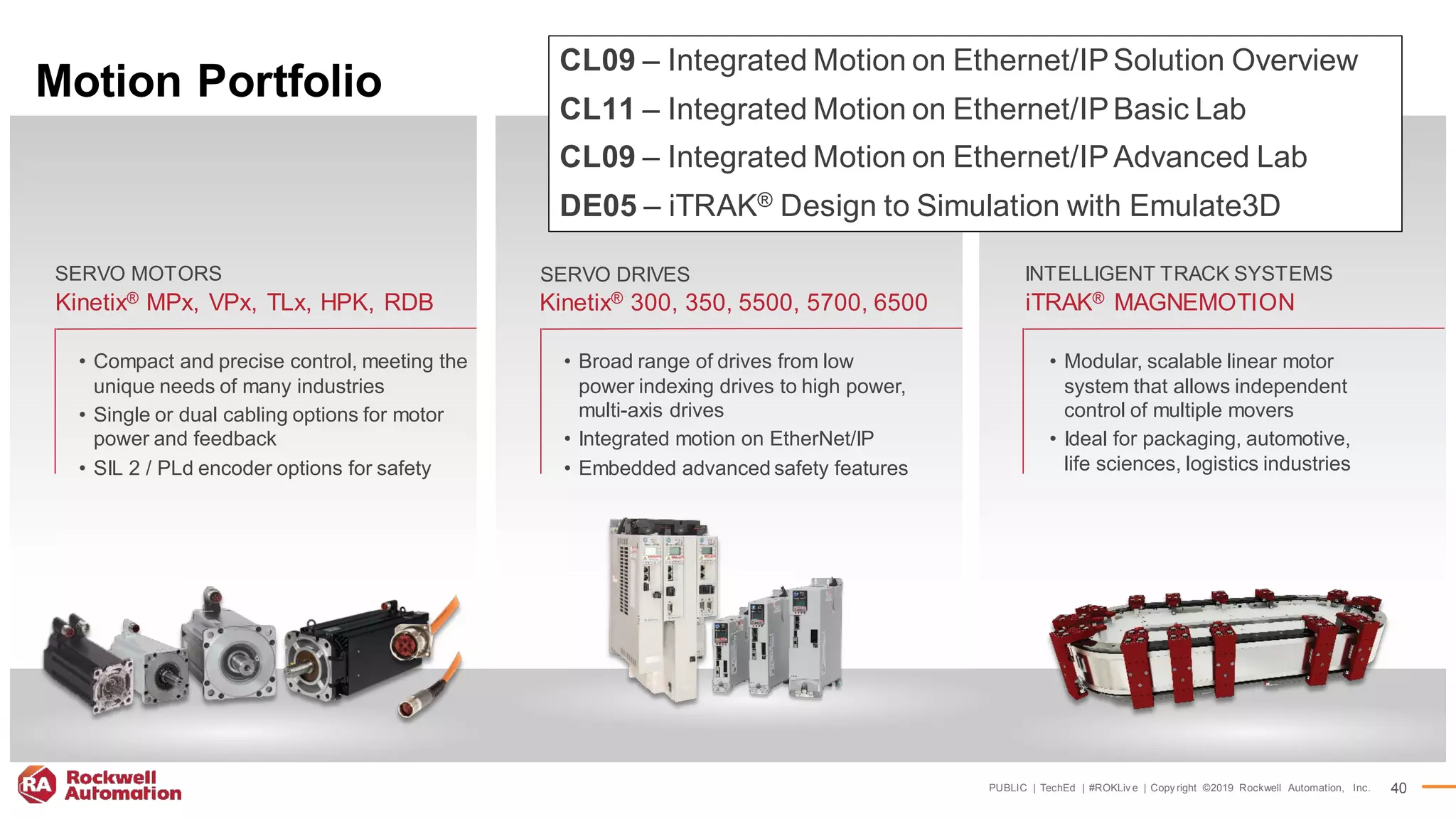

This document provides an overview and agenda for a presentation on new Rockwell Automation integrated architecture system hardware. It summarizes several new and updated controller, I/O, and communication module offerings for CompactLogix and ControlLogix platforms, including enhanced performance, security, and availability features. Safety-rated controllers are also highlighted.