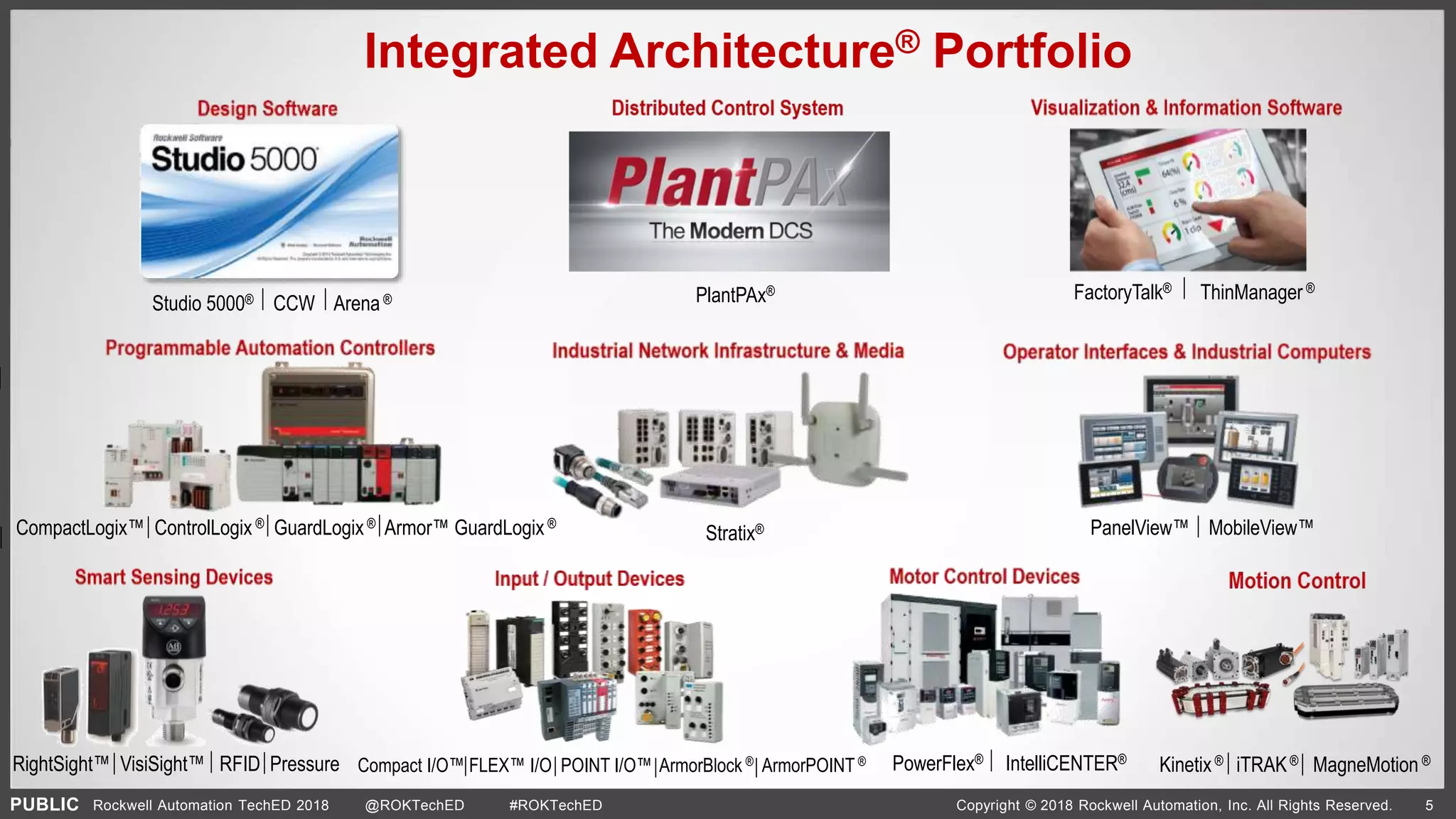

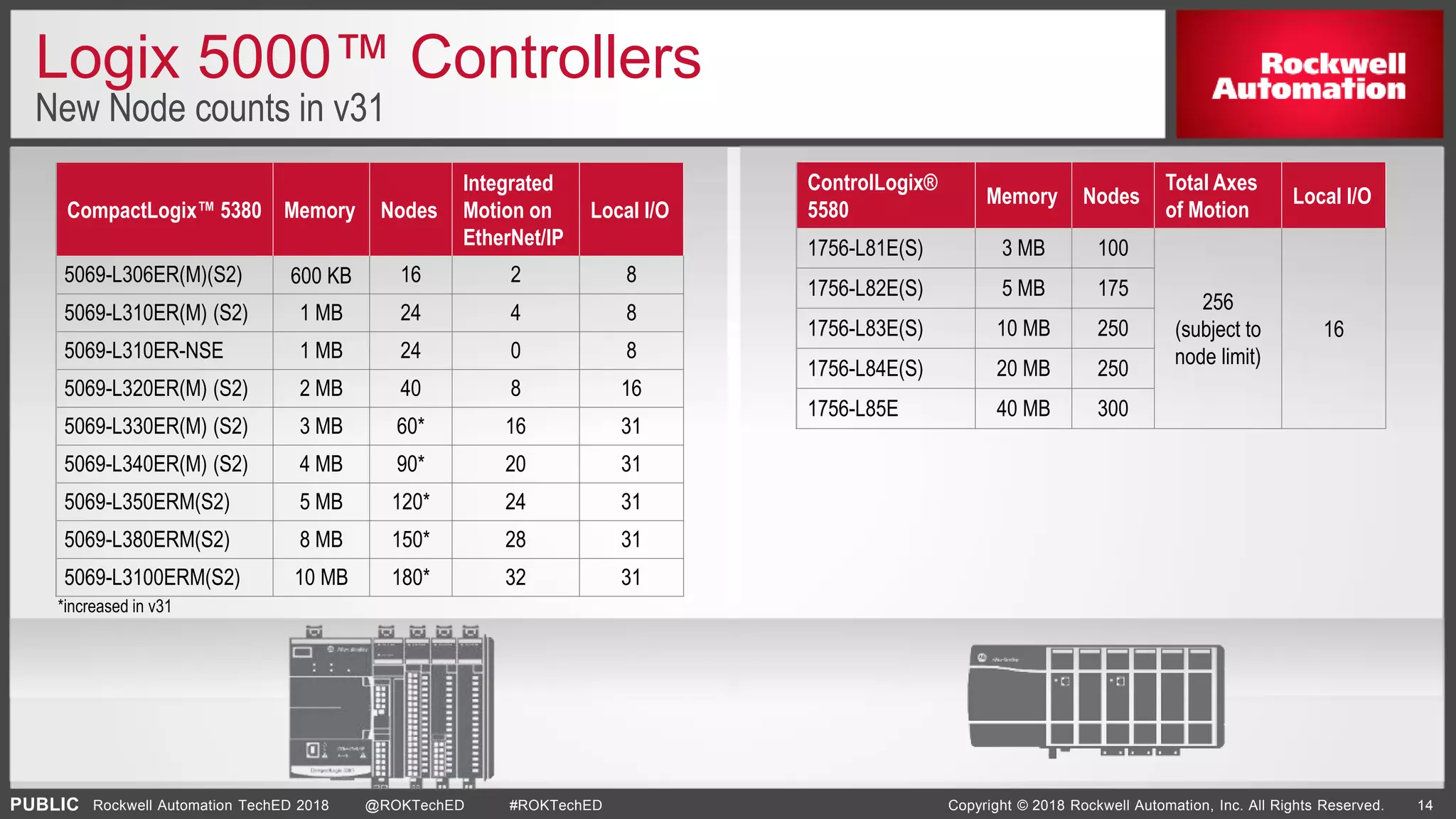

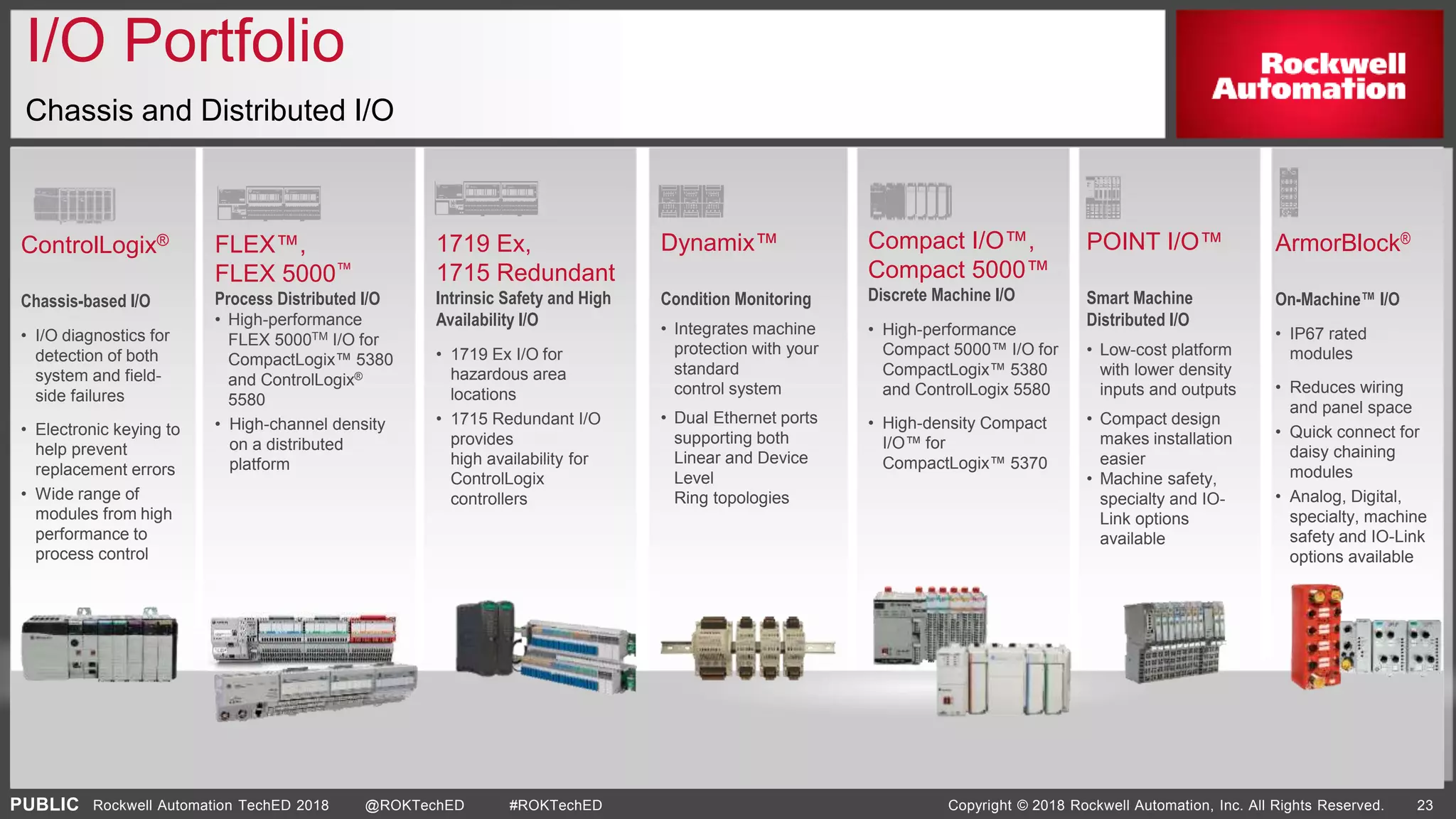

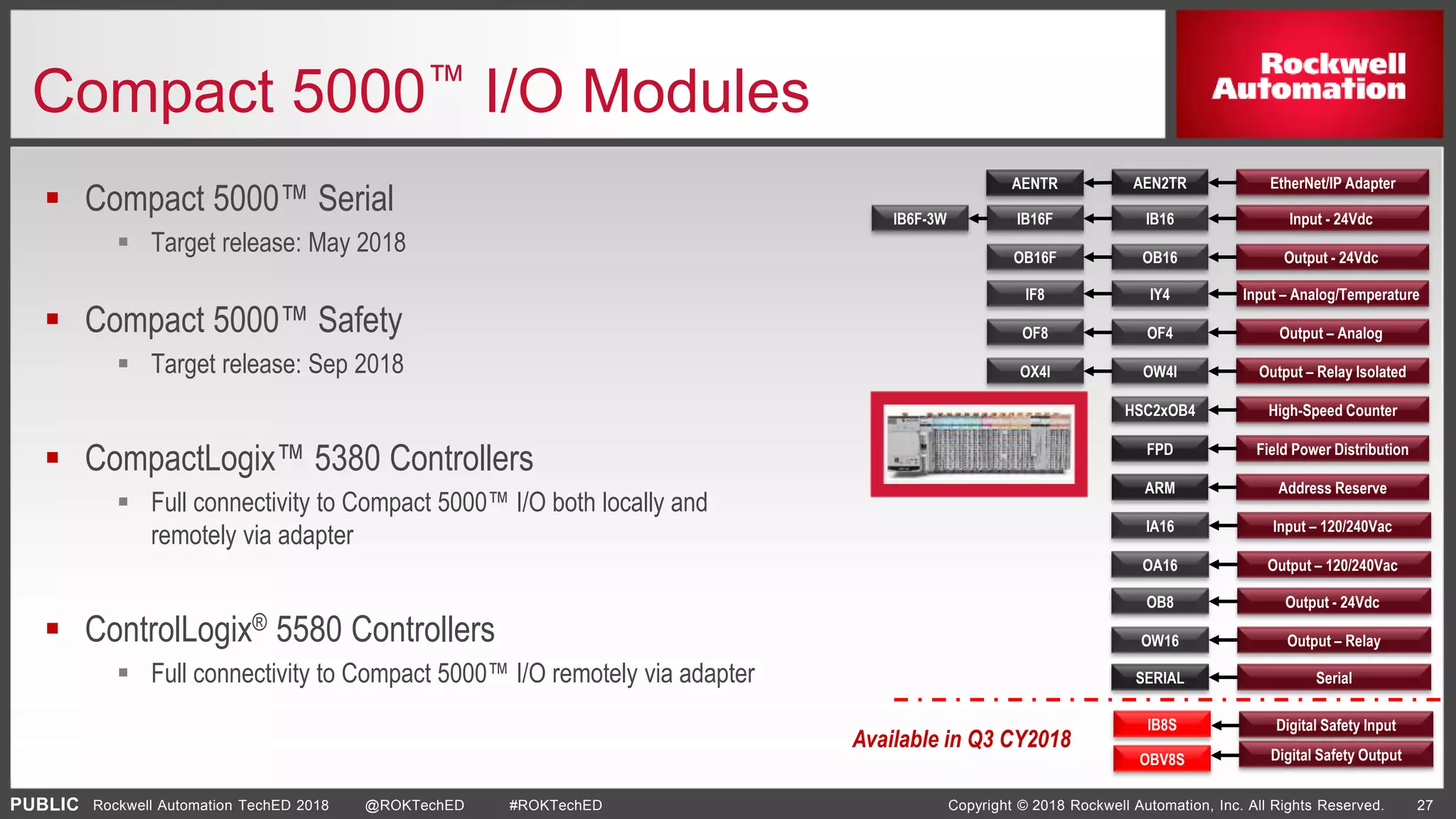

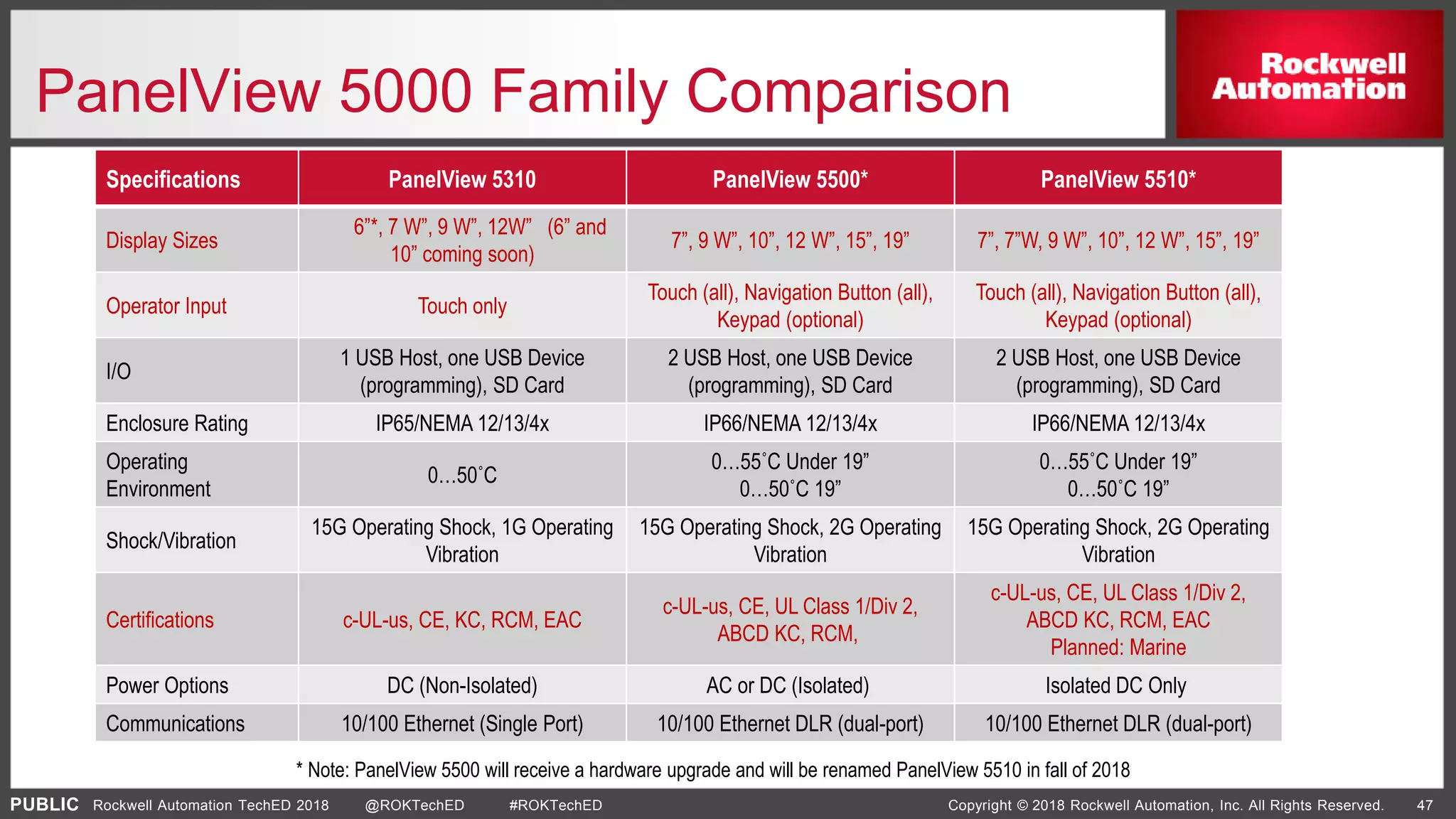

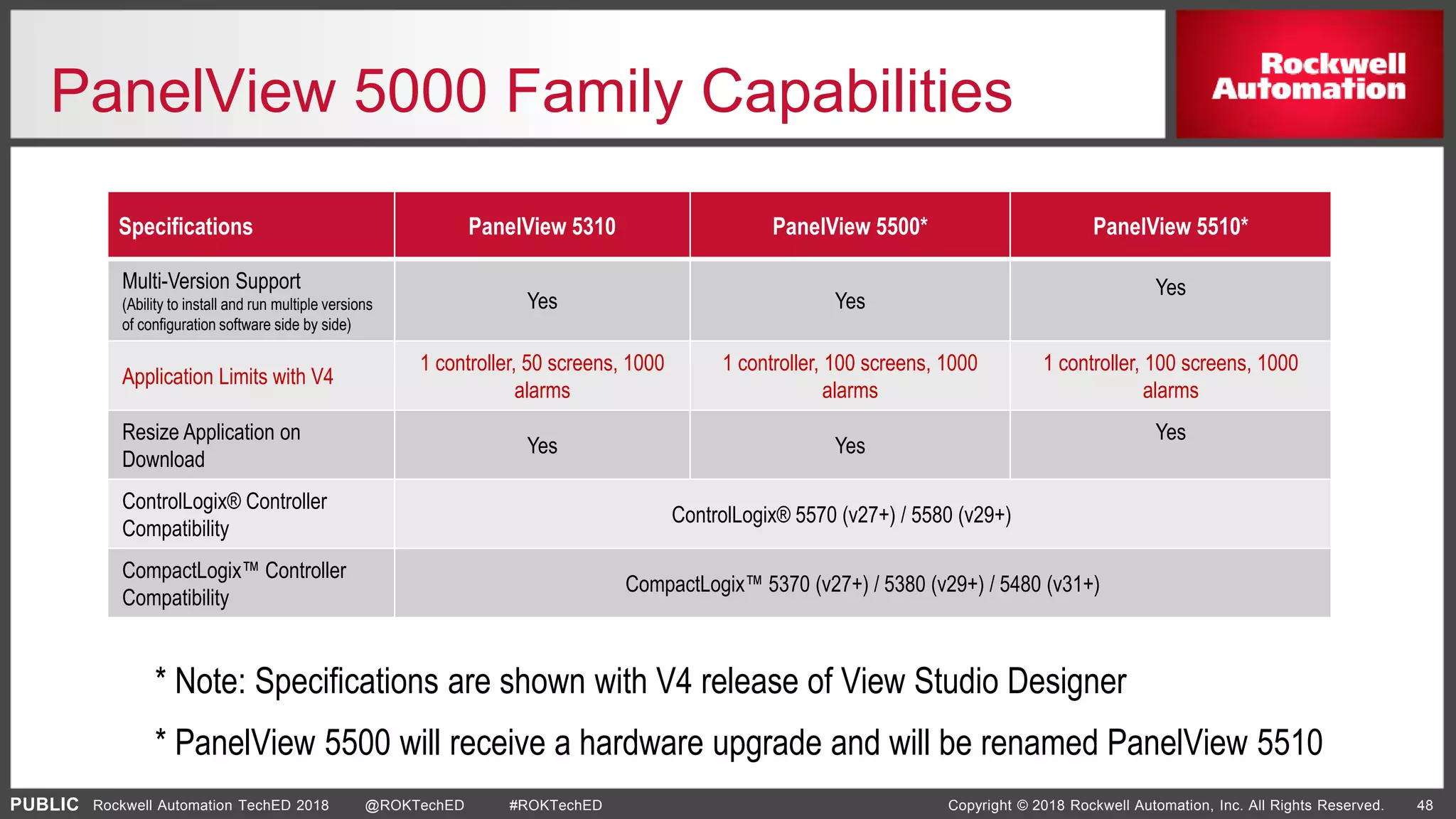

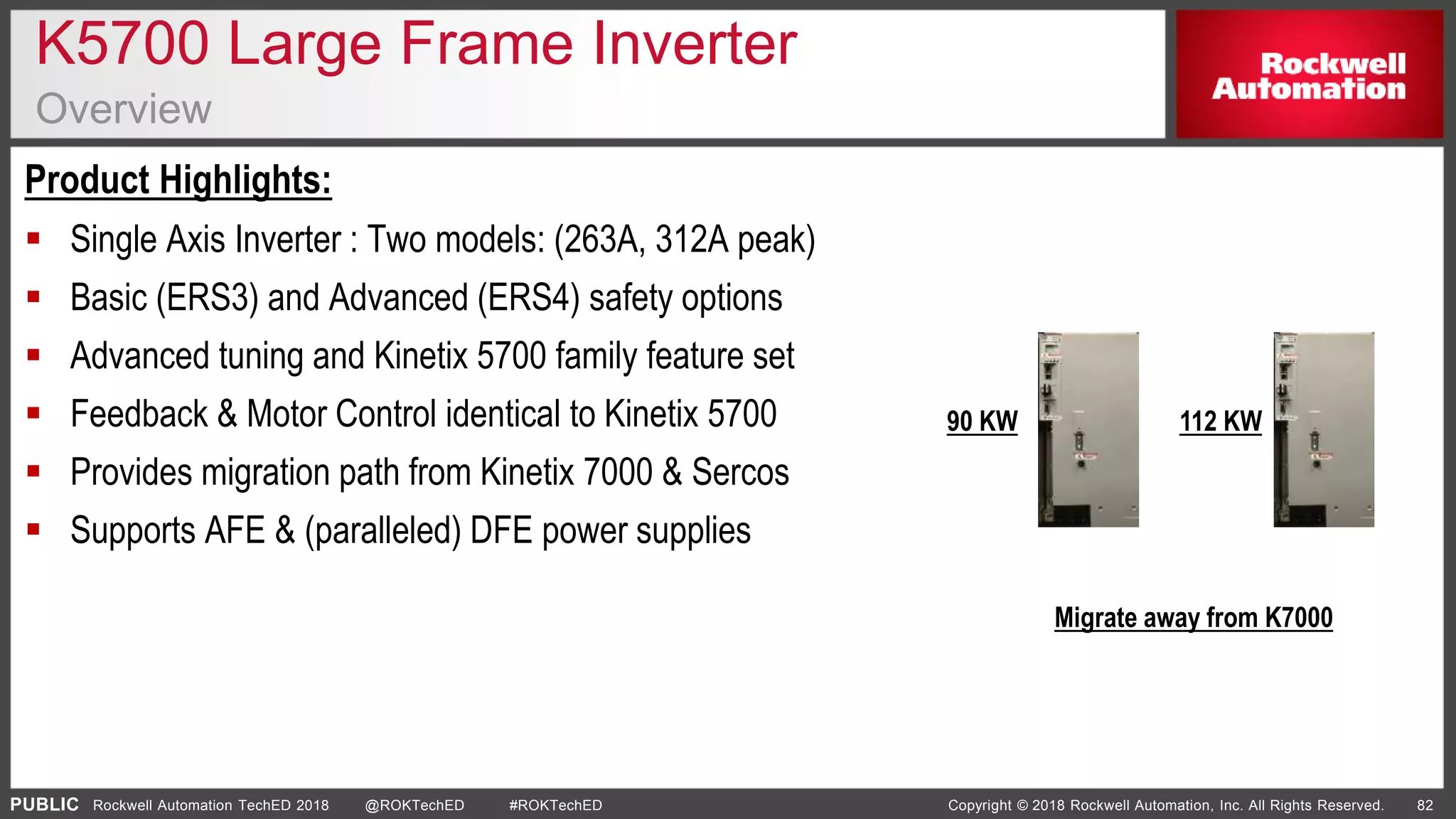

The document outlines updates to Rockwell Automation's integrated architecture system presented at the 2018 TechEd event, highlighting new hardware and software features. It includes detailed information on controllers, motion drives, and the security improvements of various products, emphasizing enhanced performance, scalability, and real-time operations. Several new tools and software enhancements are also mentioned to optimize programming and system integration.

![PUBLIC Copyright © 2018 Rockwell Automation, Inc. All Rights Reserved. 83Rockwell Automation TechED 2018 @ROKTechED #ROKTechED

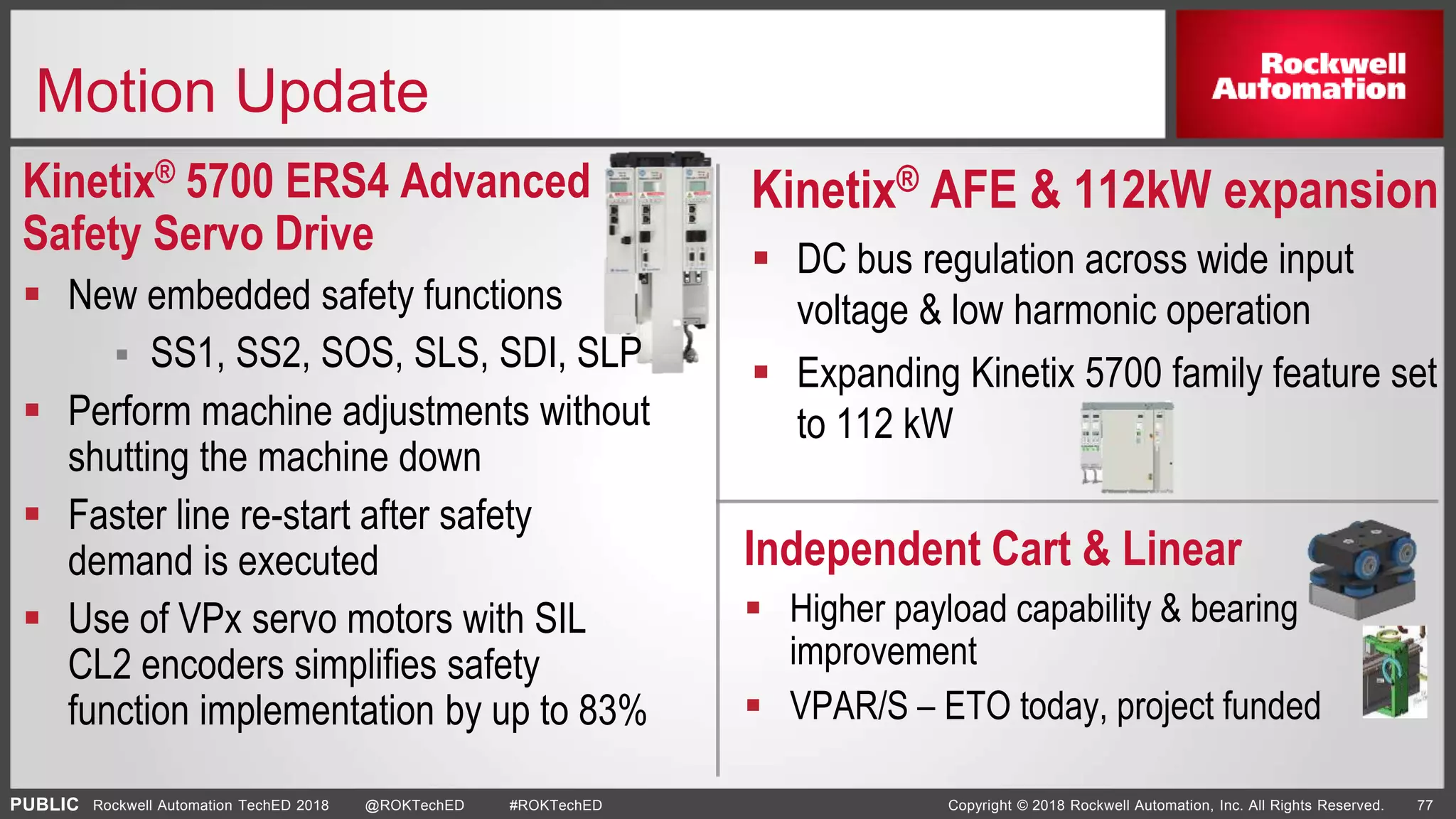

Independent Cart & Linear

MagneMover LITE, iTRAK, VPAR/S

Feature What are we doing Why are we doing it Target AFC

Wheeled Puck Increasing payload 5X for

standard and tandem pucks

• Enable MagneMover LITE to be used up

to 10 kg payloads (~ 2 kg today)

CY2018

Q2

High Payload Switch Introducing new switch with

full length flipper

• Increases switch capabilities to match

wheeled puck

• Increases layout flexibility

CY2018

Q3

TriMax™

High Performance

Bearing System

New rail and vehicle • More flexibility for new geometries

• Longer bearing life

• Reduced maintenance

Released!

Single Cable Interface VPL based linear

actuator & stage

[VPAR & VPAS]

• Simplify wiring and troubleshooting

• Alignment to Kinetix

• Existing customer demand (ETO today)

CY2018

Q4](https://image.slidesharecdn.com/whatsnewintheintegratedarchitecturehardware-180613164640/75/What-s-new-in-the-integrated-architecture-hardware-65-2048.jpg)