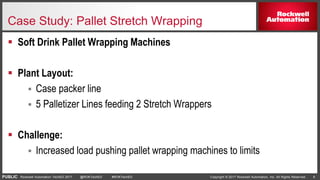

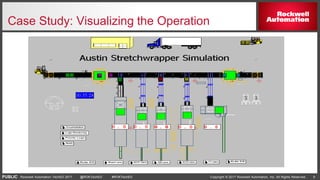

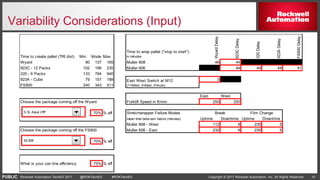

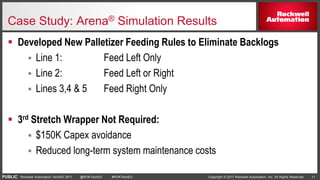

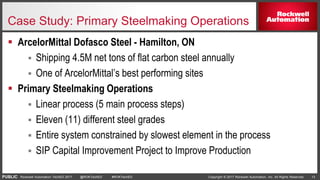

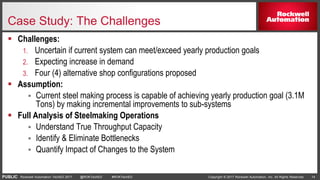

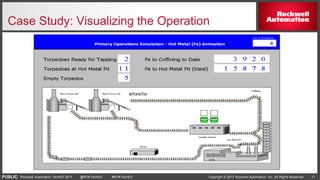

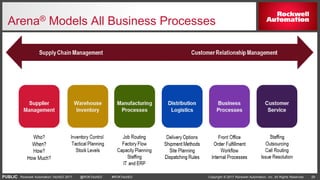

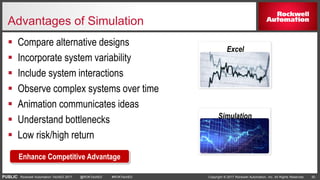

The document discusses the use of Arena simulation software by Rockwell Automation for improving operational efficiency in manufacturing processes, including case studies in pallet stretch wrapping and primary steelmaking. It highlights the identification of bottlenecks, optimization of feeding rules, and the assessment of system performance under variable conditions. The case studies demonstrate how simulation can aid in decision-making and lead to significant cost savings and efficiency improvements.