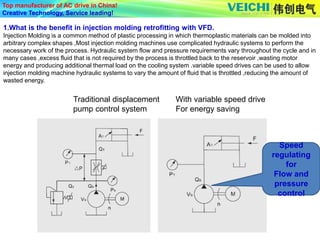

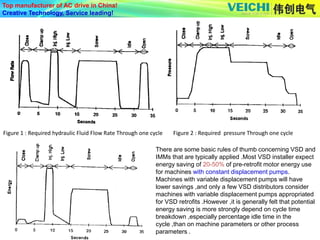

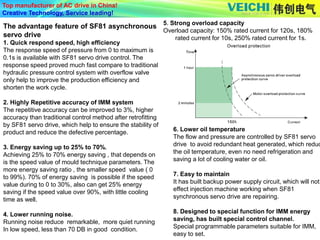

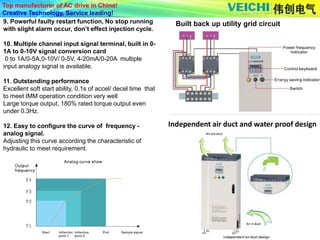

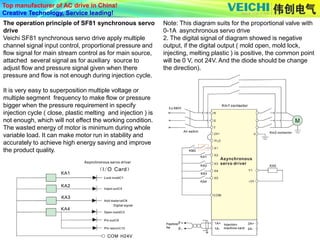

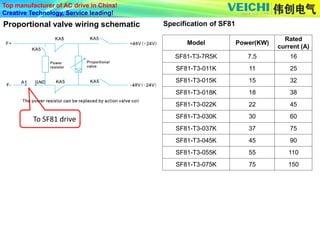

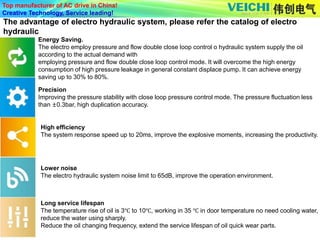

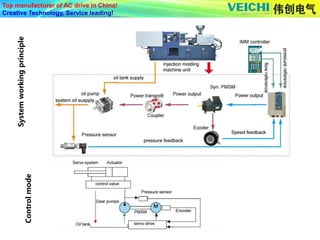

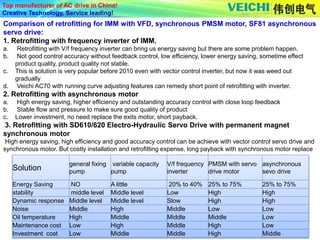

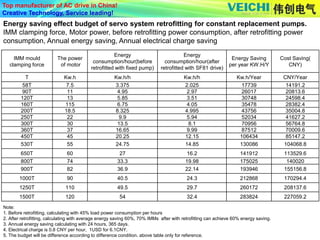

The document discusses the advantages of using variable speed drives (VSD) in injection molding machines to improve energy efficiency, resulting in energy savings of 20-60%. It emphasizes the capabilities of the SF81 asynchronous servo drive system, which enhances pressure and flow control while minimizing energy waste and operational noise. The text also compares various retrofitting options to enhance energy efficiency in injection molding, highlighting the cost-effectiveness and performance improvements provided by the SF81 system.