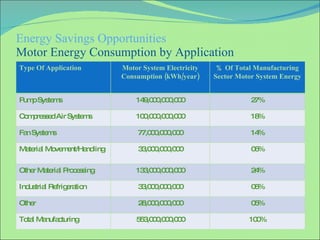

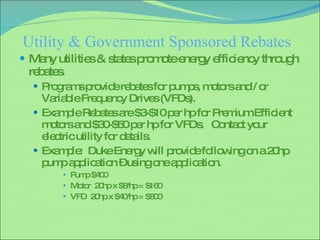

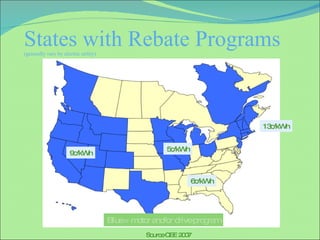

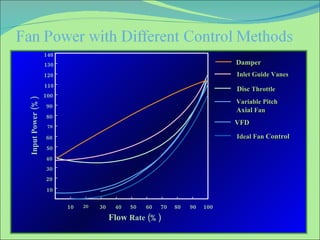

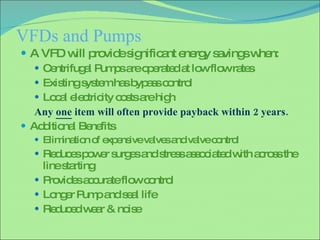

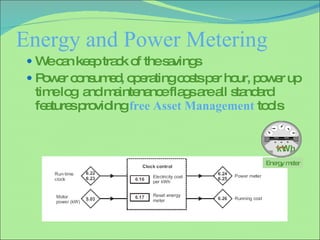

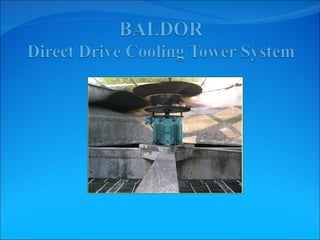

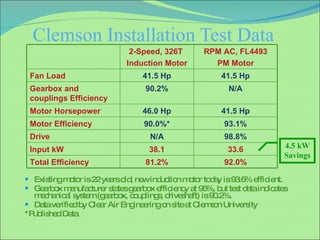

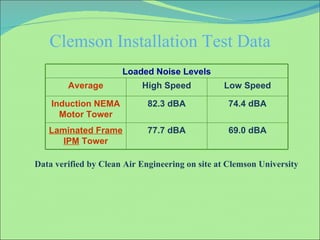

The document proposes an energy savings initiative for various industrial applications. It discusses opportunities to save energy and money in motor-driven systems like fans, pumps, compressors, and conveyors by using variable frequency drives (VFDs) and premium efficient motors. Retrofitting these systems can reduce energy consumption by up to 30% while qualifying for utility rebates. A case study at Clemson University found their direct drive cooling tower solution with Baldor motor and VFD improved efficiency from 81.2% to 92.0% while lowering noise levels.