The document summarizes information about batteries, including:

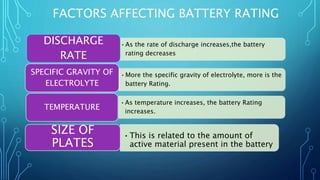

1. Battery rating is specified in ampere-hours and depends on discharge current and time until the voltage reaches a specified level. Higher temperature, electrolyte density, and plate size increase the rating.

2. Battery efficiency is the ratio of energy output during discharge to input during charging, and ranges from 80-90% for amp-hours and 70-80% for watt-hours in lead-acid batteries.

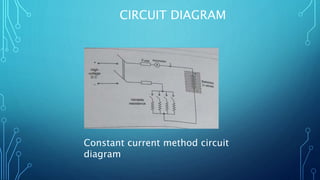

3. Battery charging methods include constant current, constant voltage, and using a rectifier to convert AC to DC. The depth of discharge indicates the safe level a battery can be used before recharging.

![BATTERY EFFICIENCY

•Mainly the battery efficiency is defined as

the ratio of output during discharging to

the input required during charging, to

regain the original state of the battery.

•It is define in two ways as,

•1] Ampere –hour efficiency or quantity

efficiency

•2]Watt – hour efficiency or energy](https://image.slidesharecdn.com/batteryppt-220727154038-9f7b4469/85/battery-ppt-pptx-5-320.jpg)

![1] AMPERE – HOUR EFFICIENCY

• It is defined as ratio of output in ampere-hours

during discharging to the input in ampere-hours

during charging. It is denoted as MAh

•% MAh=[Current x Time on discharge]/[Current x

Time on charge] x 100

•• For lead acid battery, it ranges between 80 % to

90 %.](https://image.slidesharecdn.com/batteryppt-220727154038-9f7b4469/85/battery-ppt-pptx-6-320.jpg)

![2] WATT – HOUR EFFICIENCY

• It is defined as the ratio of output in watt-hours during discharging to

the input in watt-hours during charging. It is denoted as MWh

• % mWh= [{Voltage during discharge (Avg)} x {Current x Time at

discharge}] x 100

• [ Voltage during charge (average)] x [Currentx Time at charge]

• % mWh= mAh x[ Avg voltage during discharge]

• [Avg voltage during charge ]

• For lead acid battery, watt-hour efficiency ranges between 70 % to 80

%.](https://image.slidesharecdn.com/batteryppt-220727154038-9f7b4469/85/battery-ppt-pptx-7-320.jpg)

![BATTERY CHARGING

• During charging, the chemical action takes place which is exactly opposite to that of

discharging Thus current in opposite direction to that at the time of discharge, is

passed through the battery For this the voltage applied is in excess of the voltage of

the battery or cell. The battery voltage acts in opposite direction to that of the applied

voltage and hence called back e.m.f. The charging current can be obtained as

• Charging Current = [Ea – Eb] / [R + r]

• Ea = Applied voltage

• Eb = Back e.m.f i.e battery voltage

• R = Exteral resistance in the circuit

• r = Internal resistance of the battery

• The charging current must be adjusted such that the temperature of the electrolyte

will not increase beyond 100° to 110 °F.](https://image.slidesharecdn.com/batteryppt-220727154038-9f7b4469/85/battery-ppt-pptx-8-320.jpg)