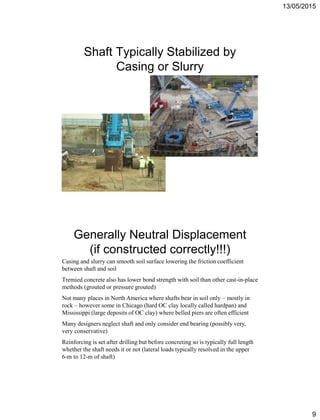

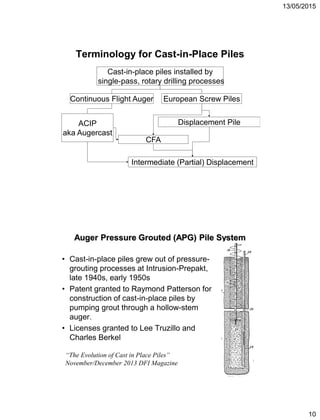

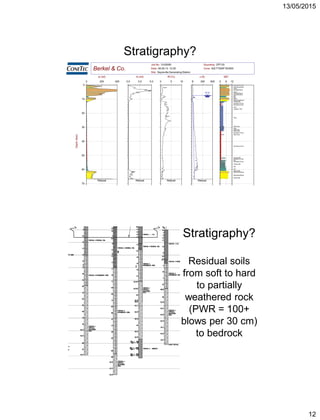

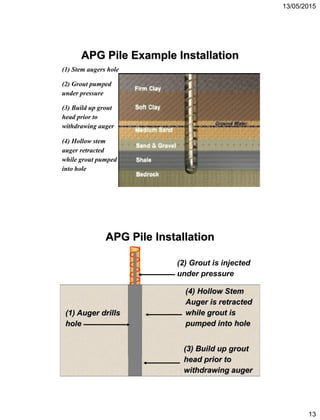

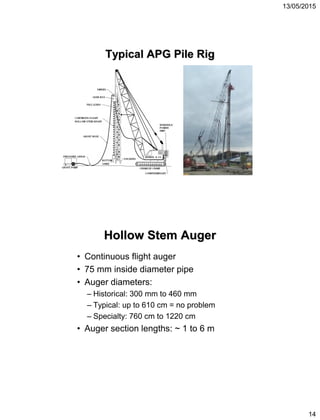

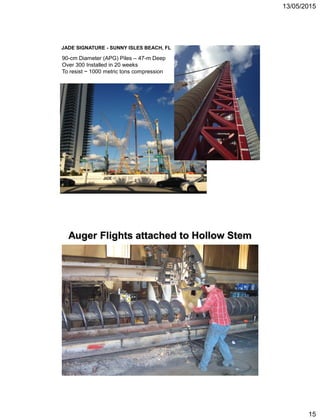

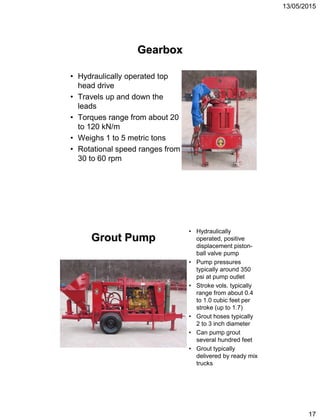

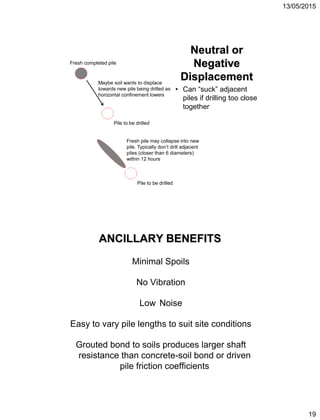

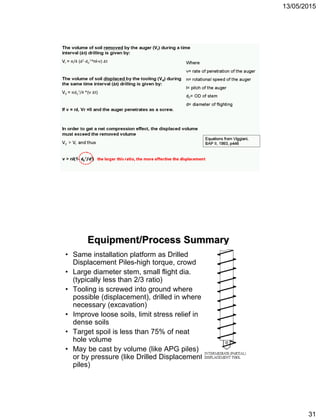

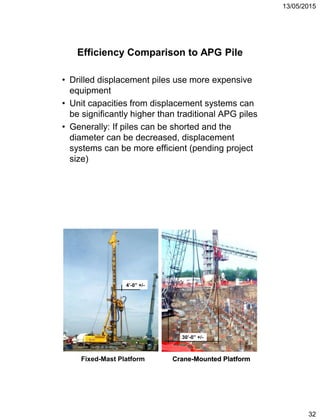

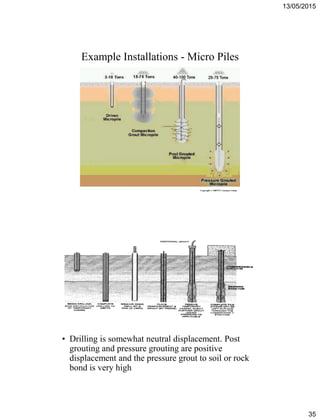

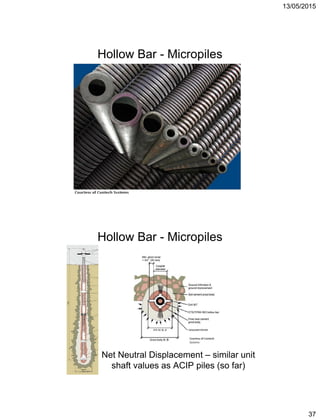

This document discusses different deep foundation installation methods including precast piles, cast-in-place foundations like drilled shafts, augered cast-in-place piles, and drilled displacement piles. It provides details on factors that influence foundation performance like the installation method and material used. Specific pile types and installation considerations for different soil conditions are described.