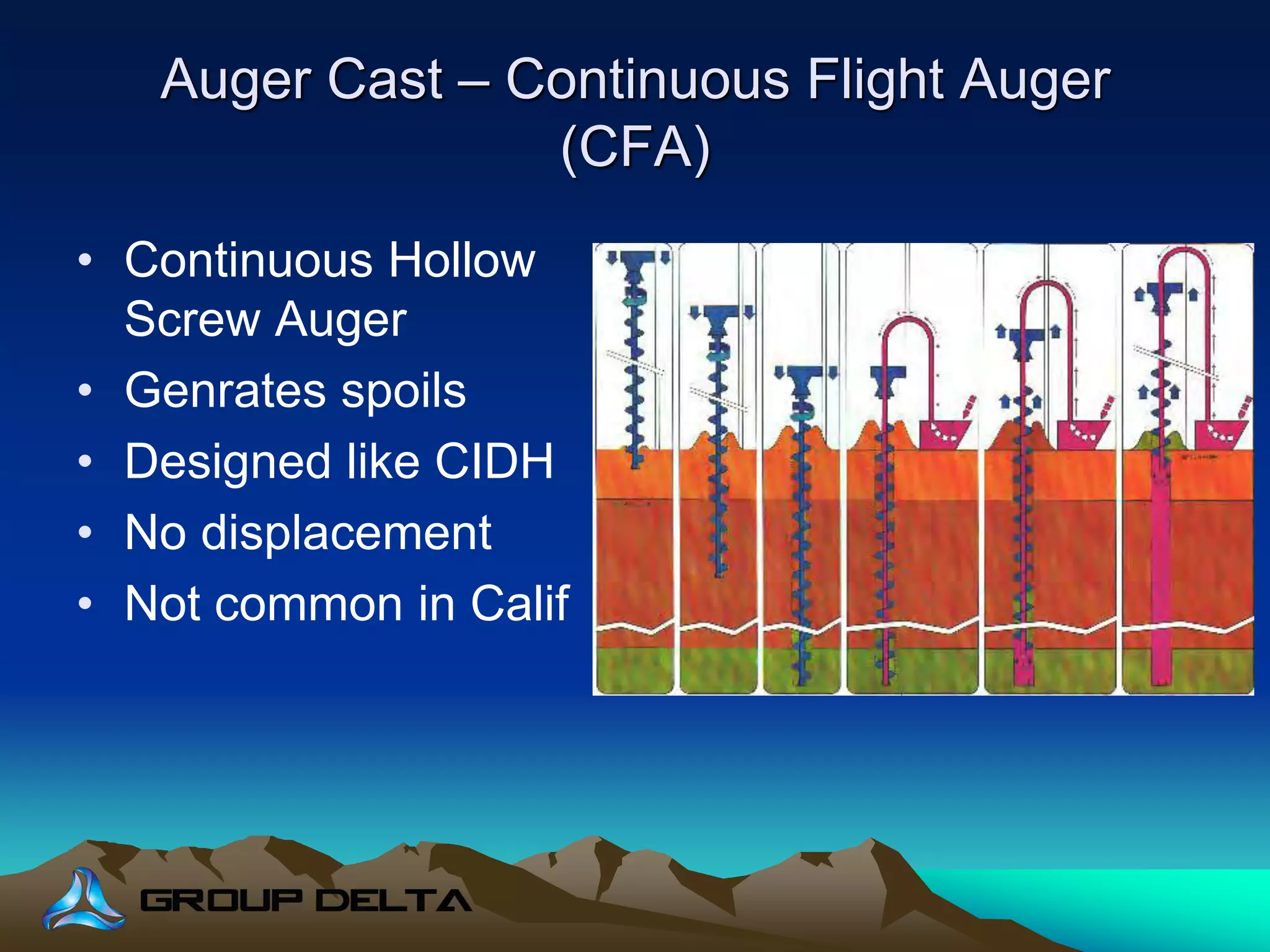

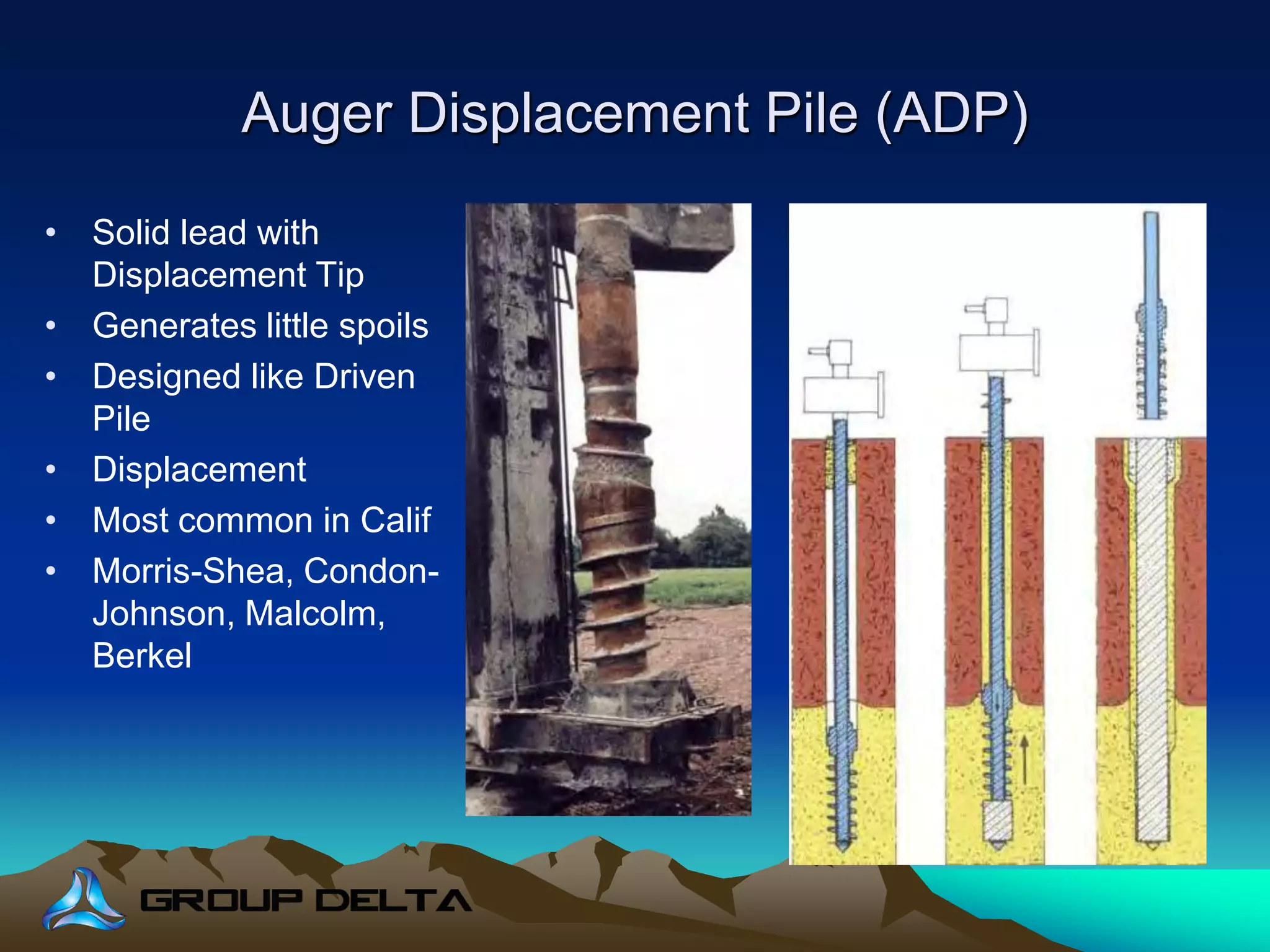

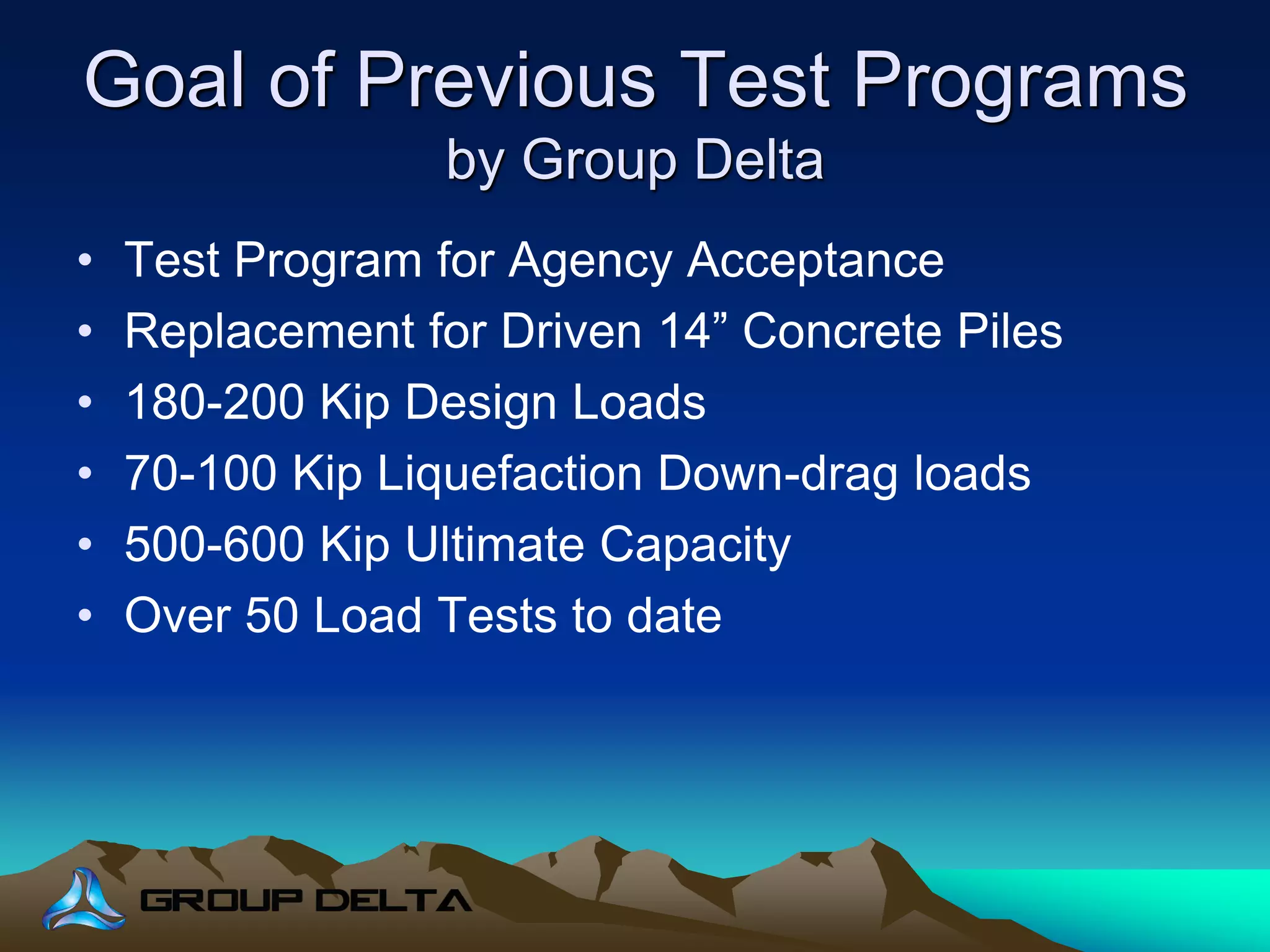

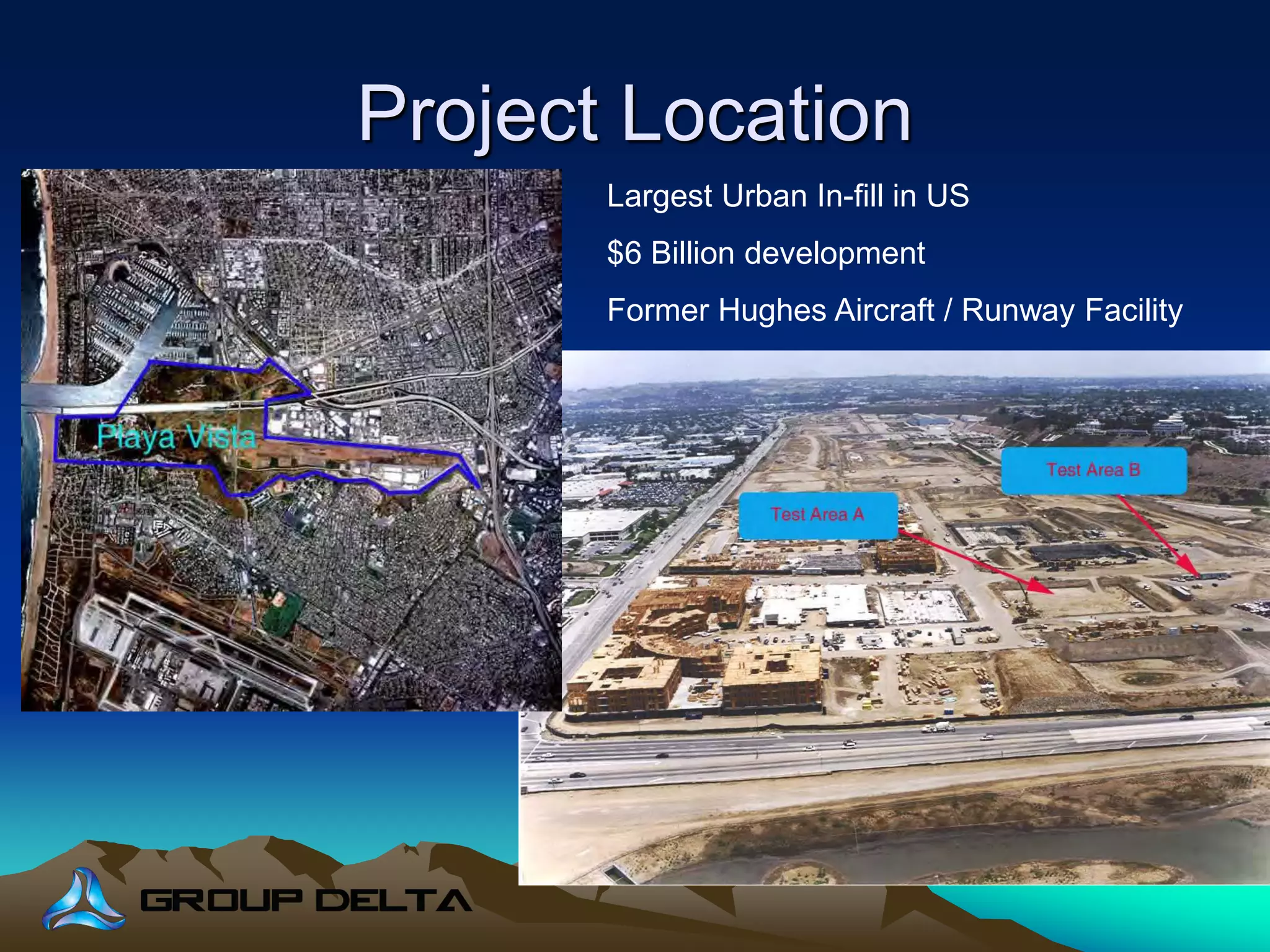

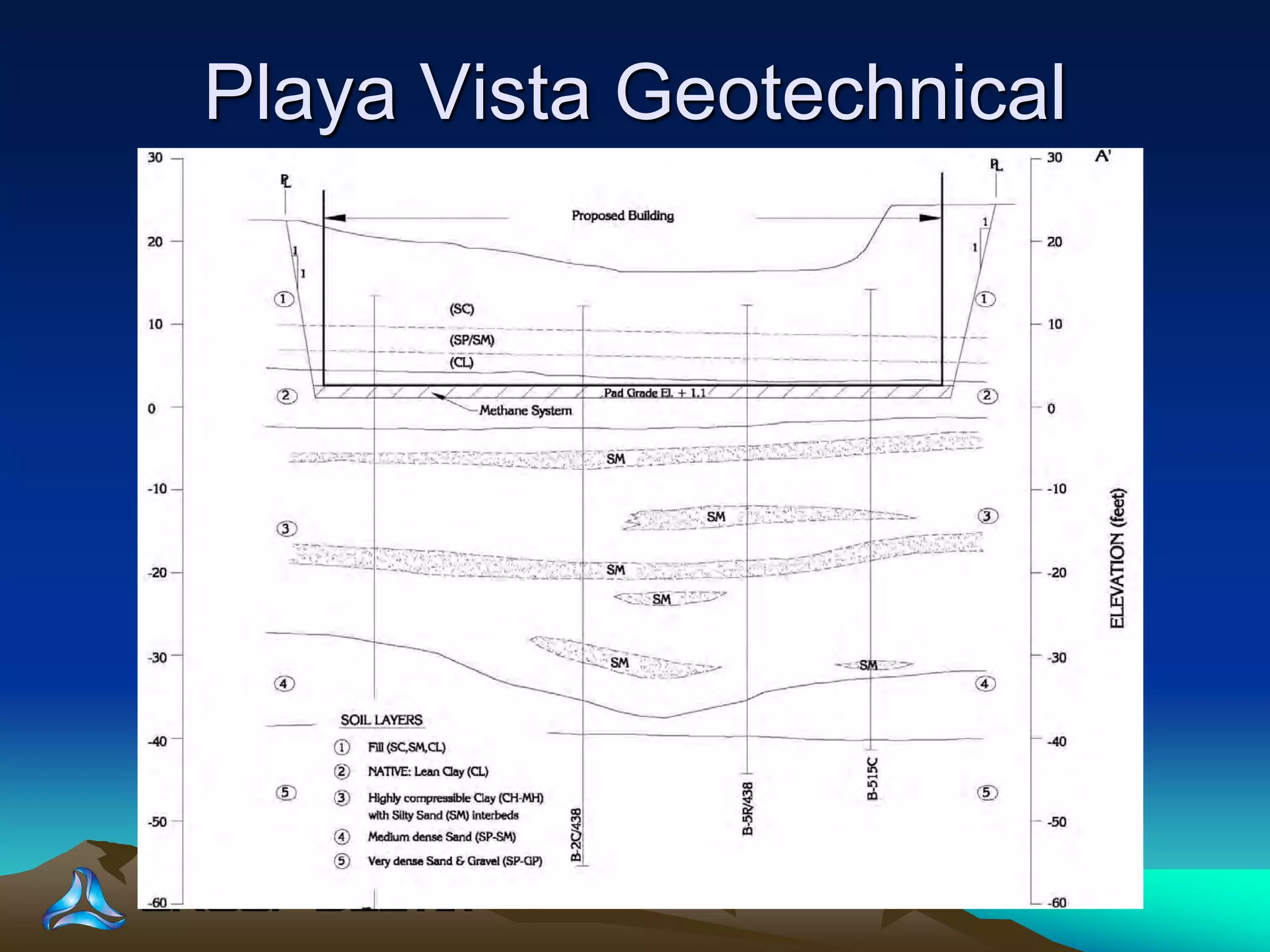

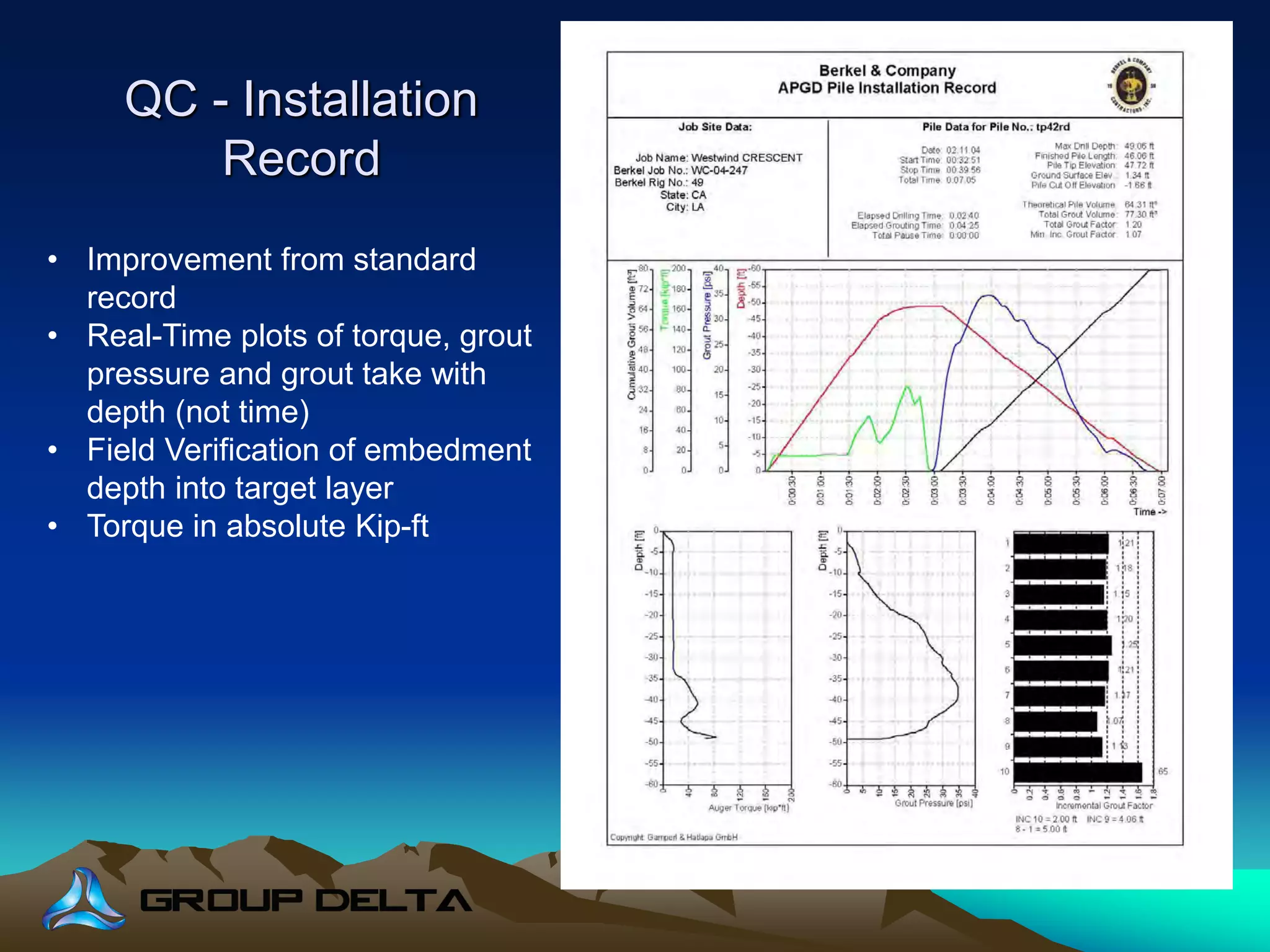

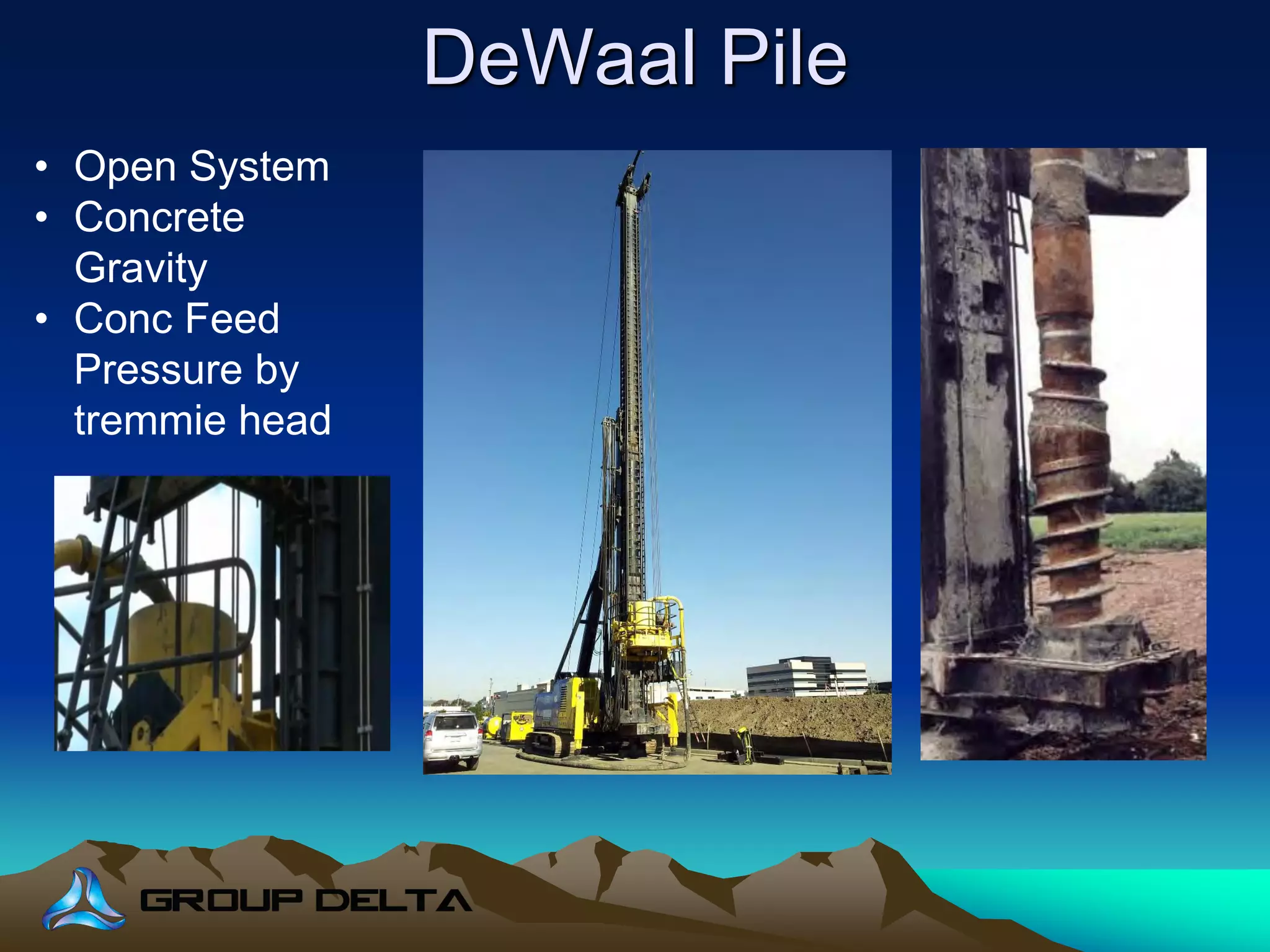

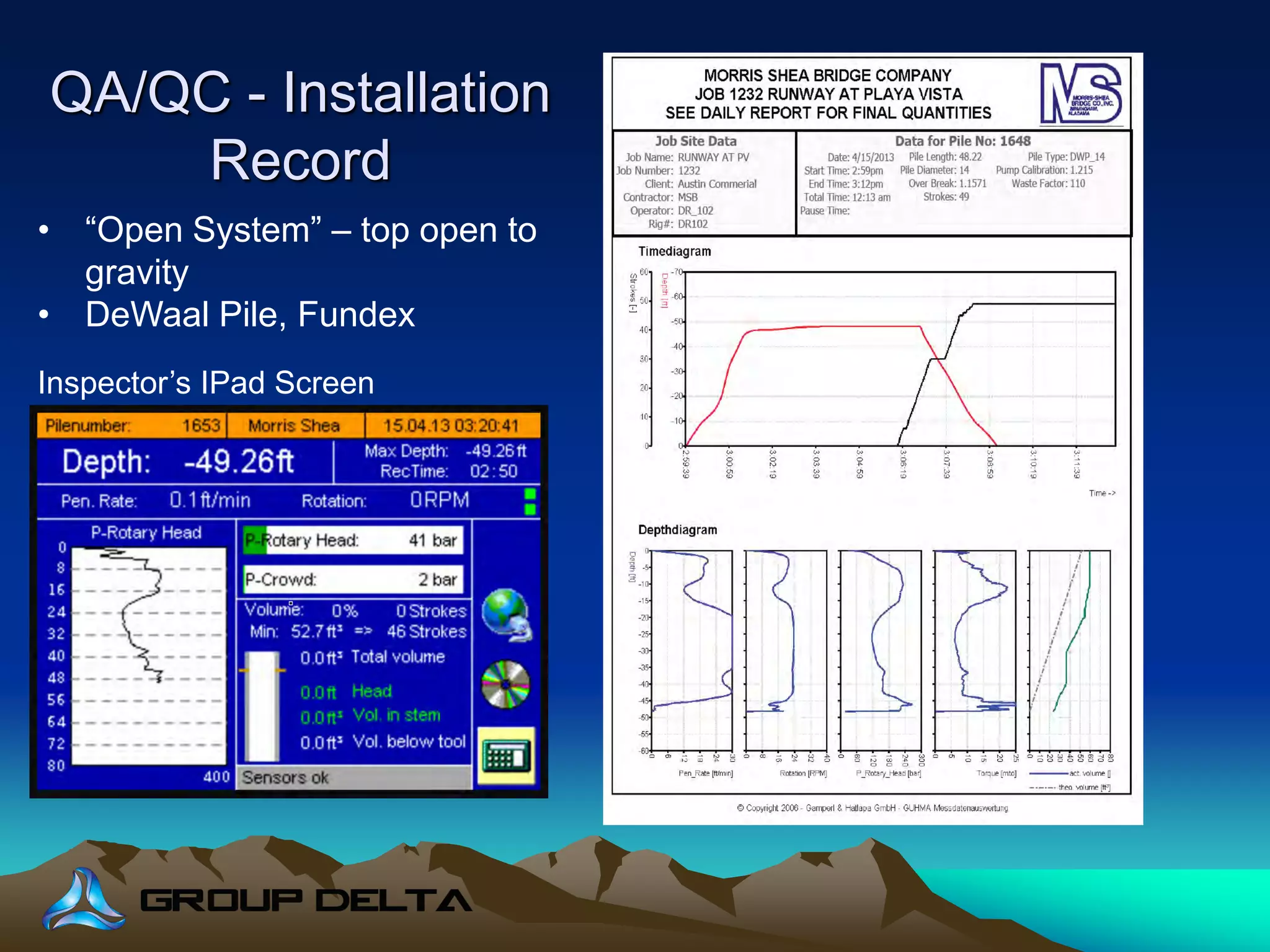

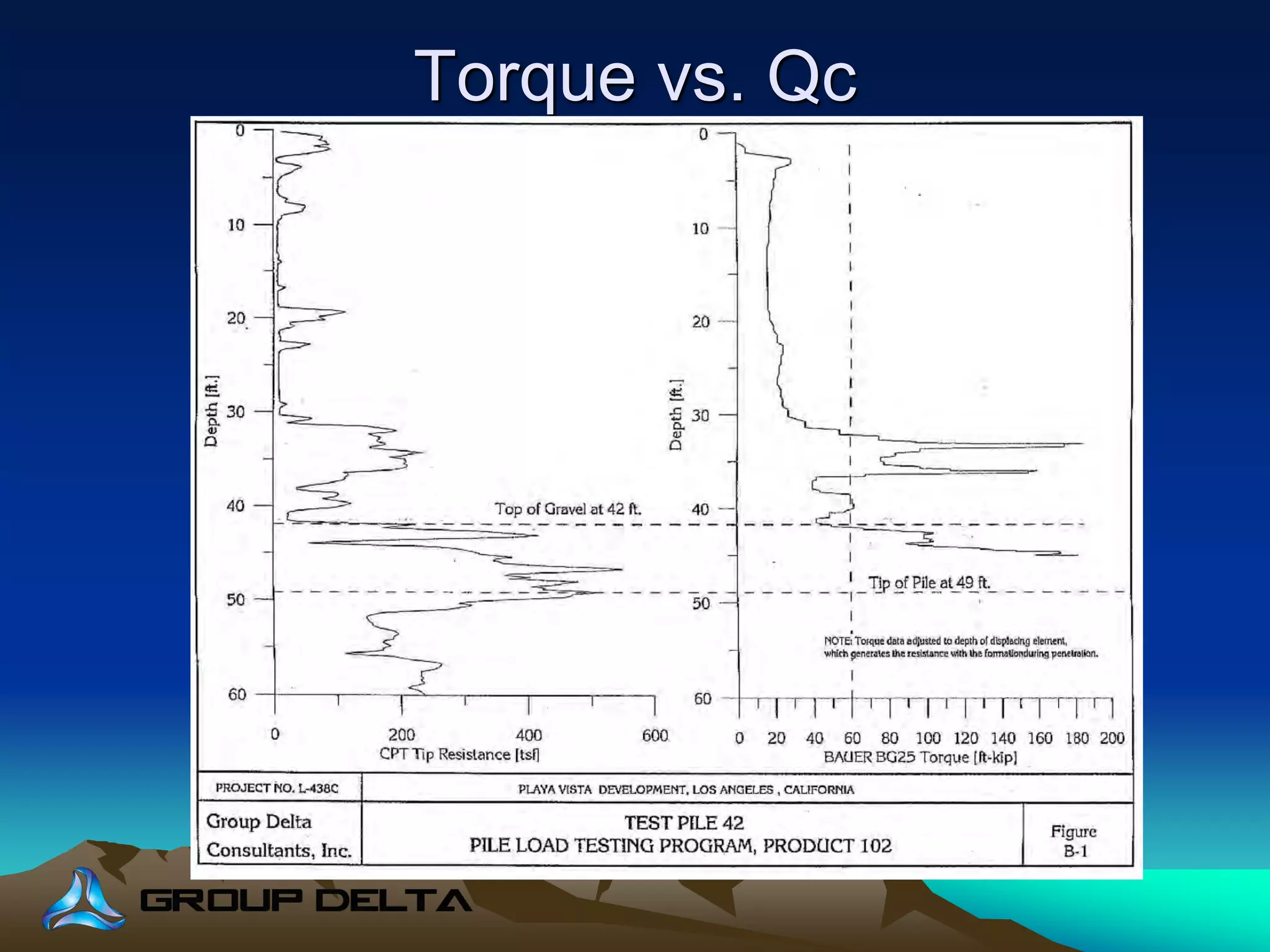

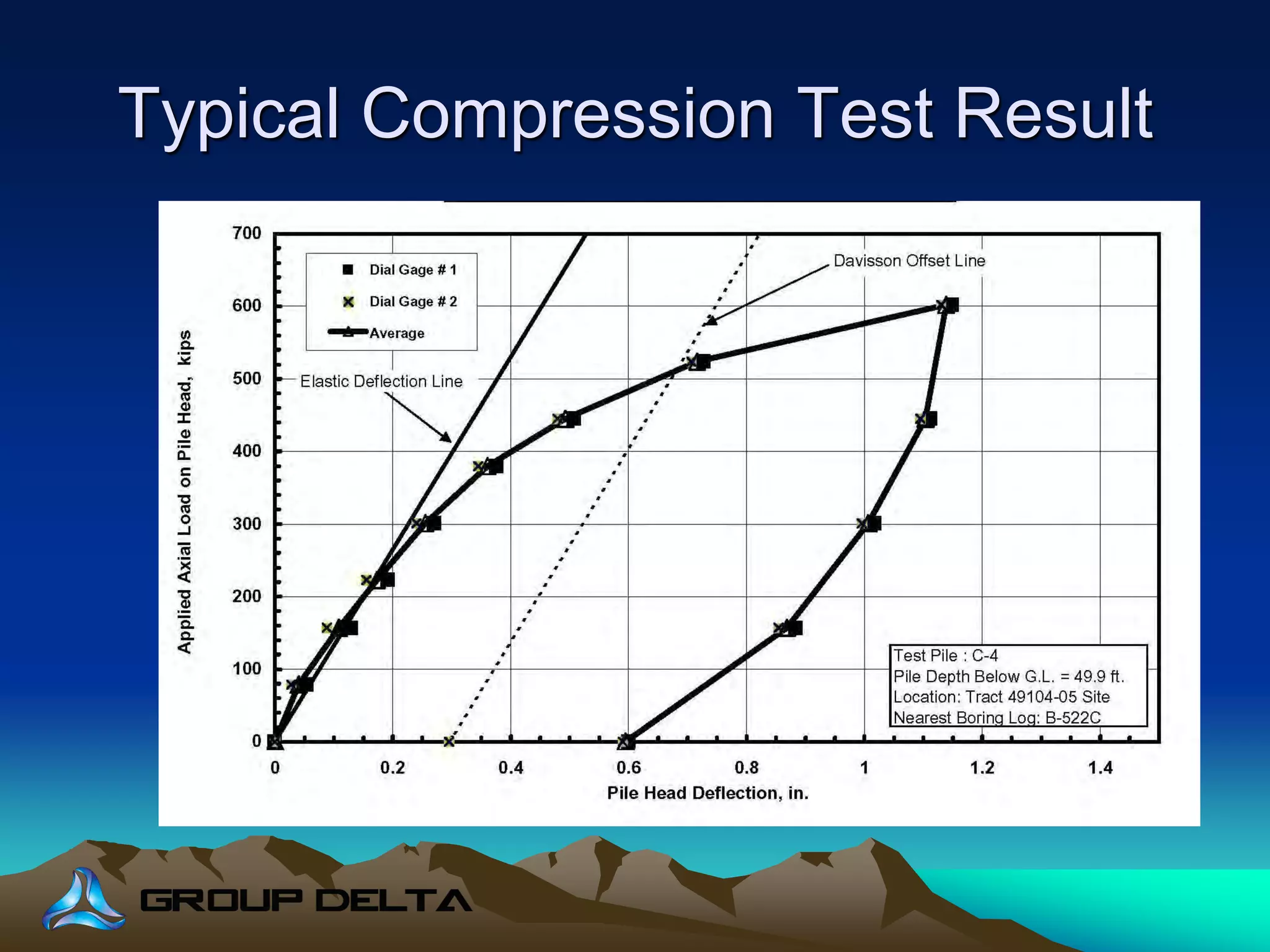

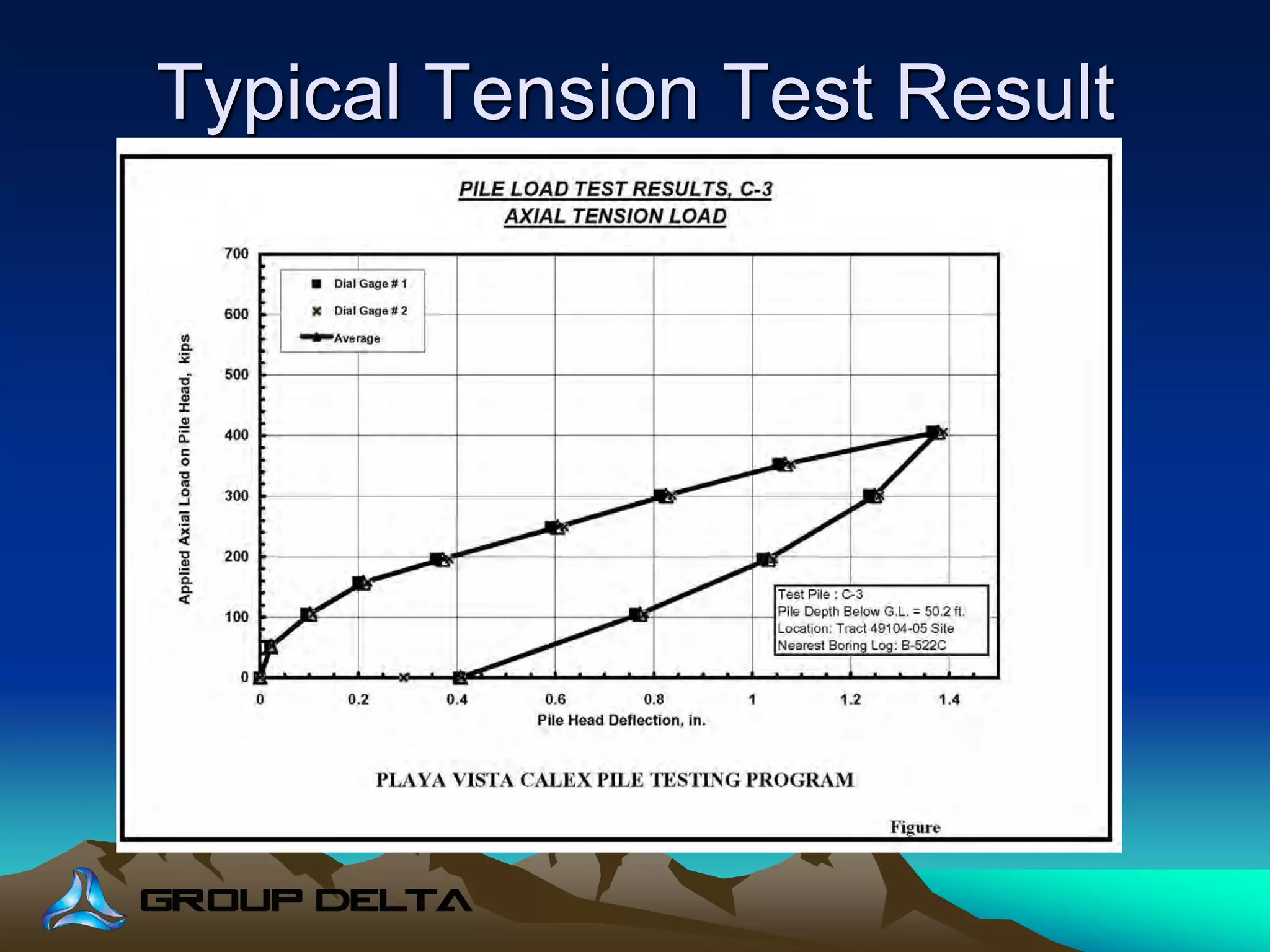

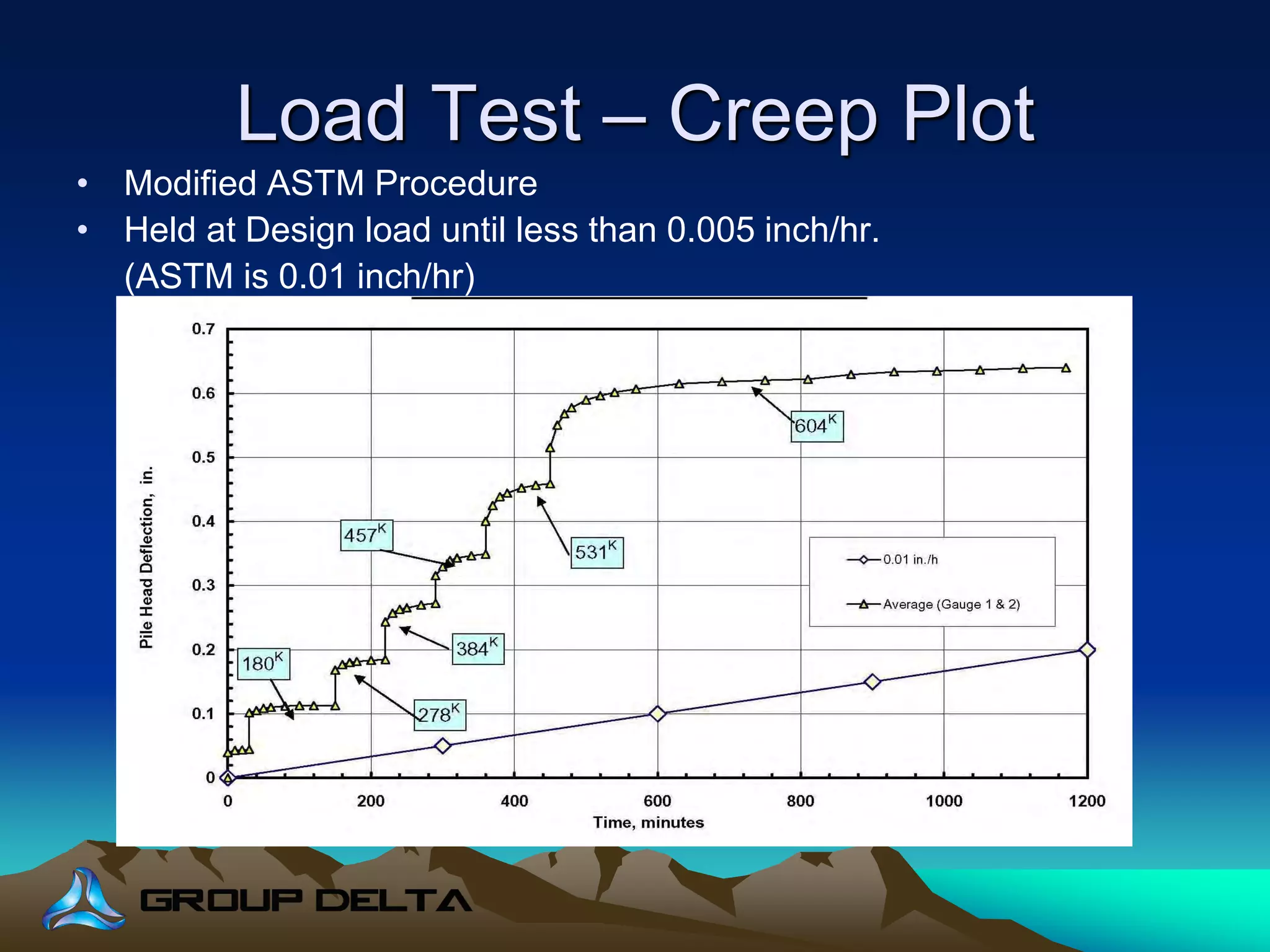

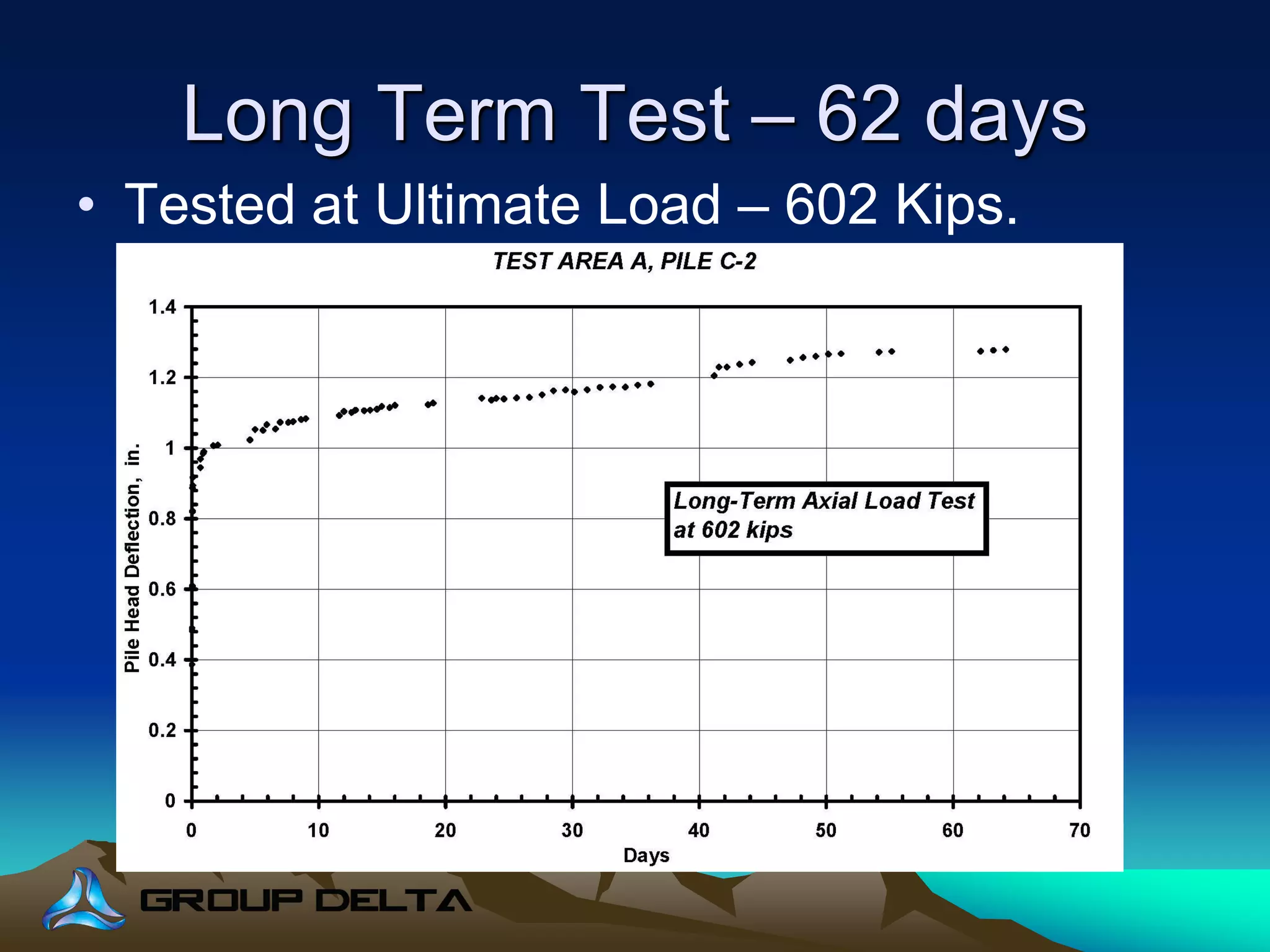

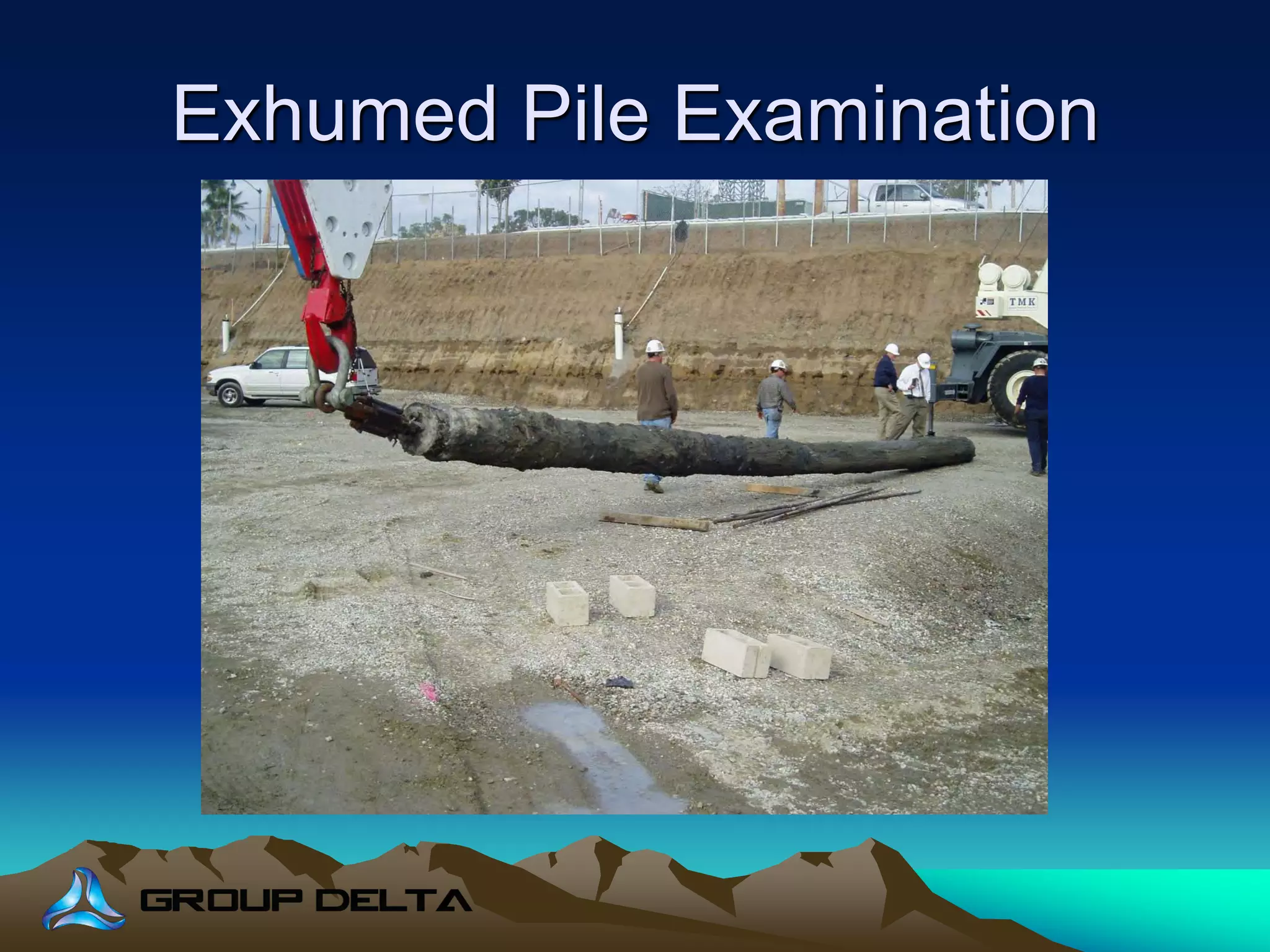

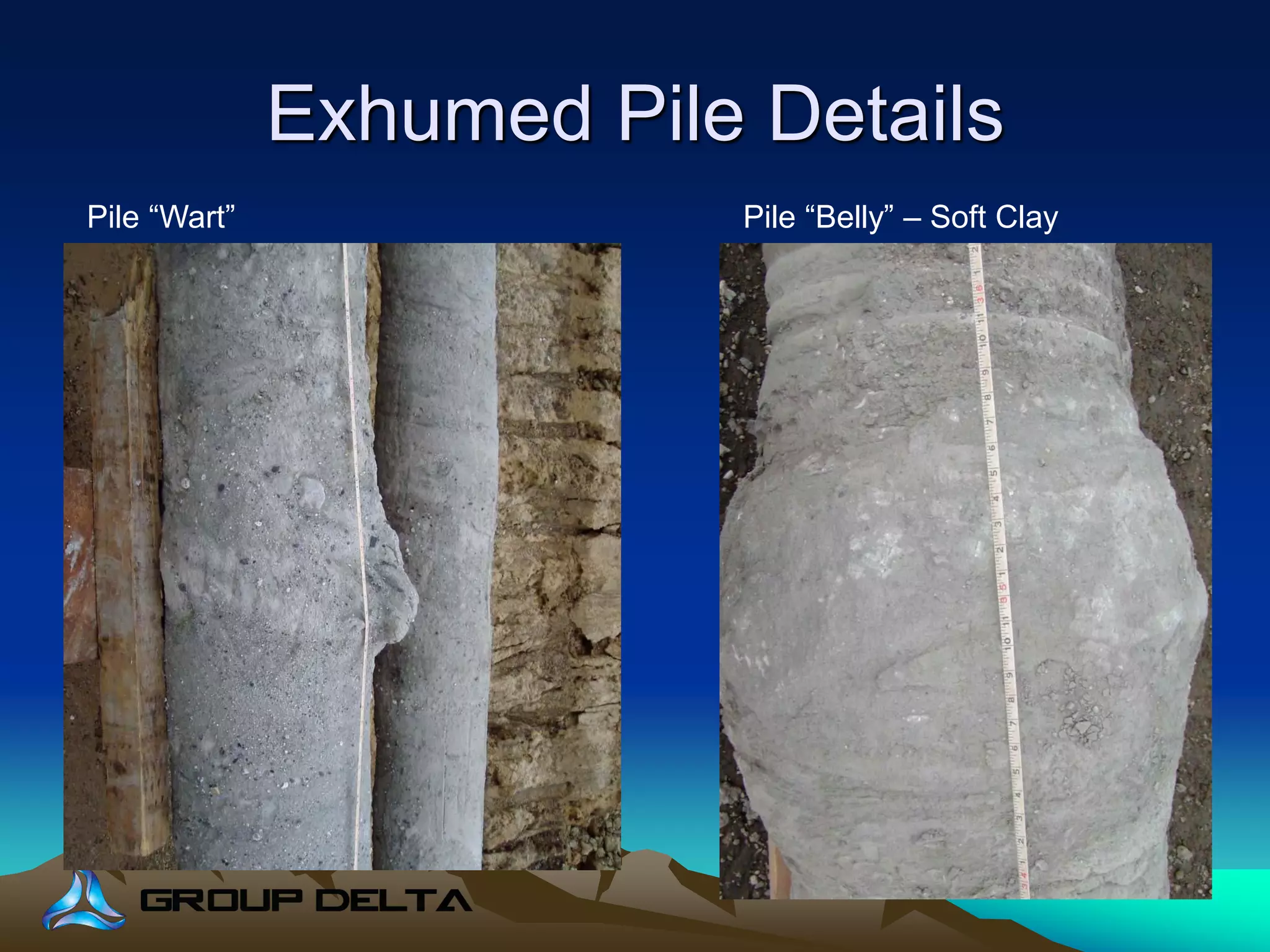

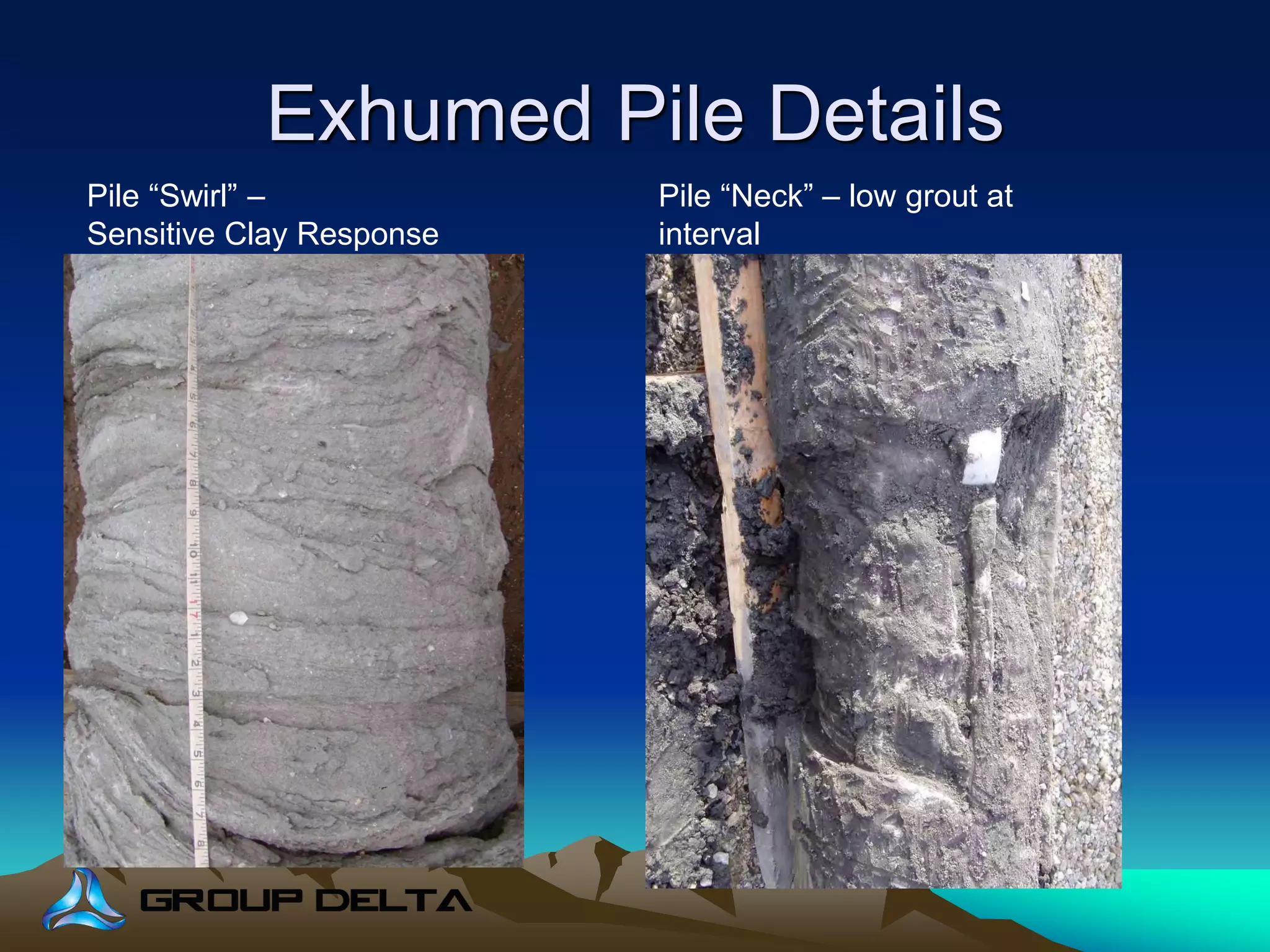

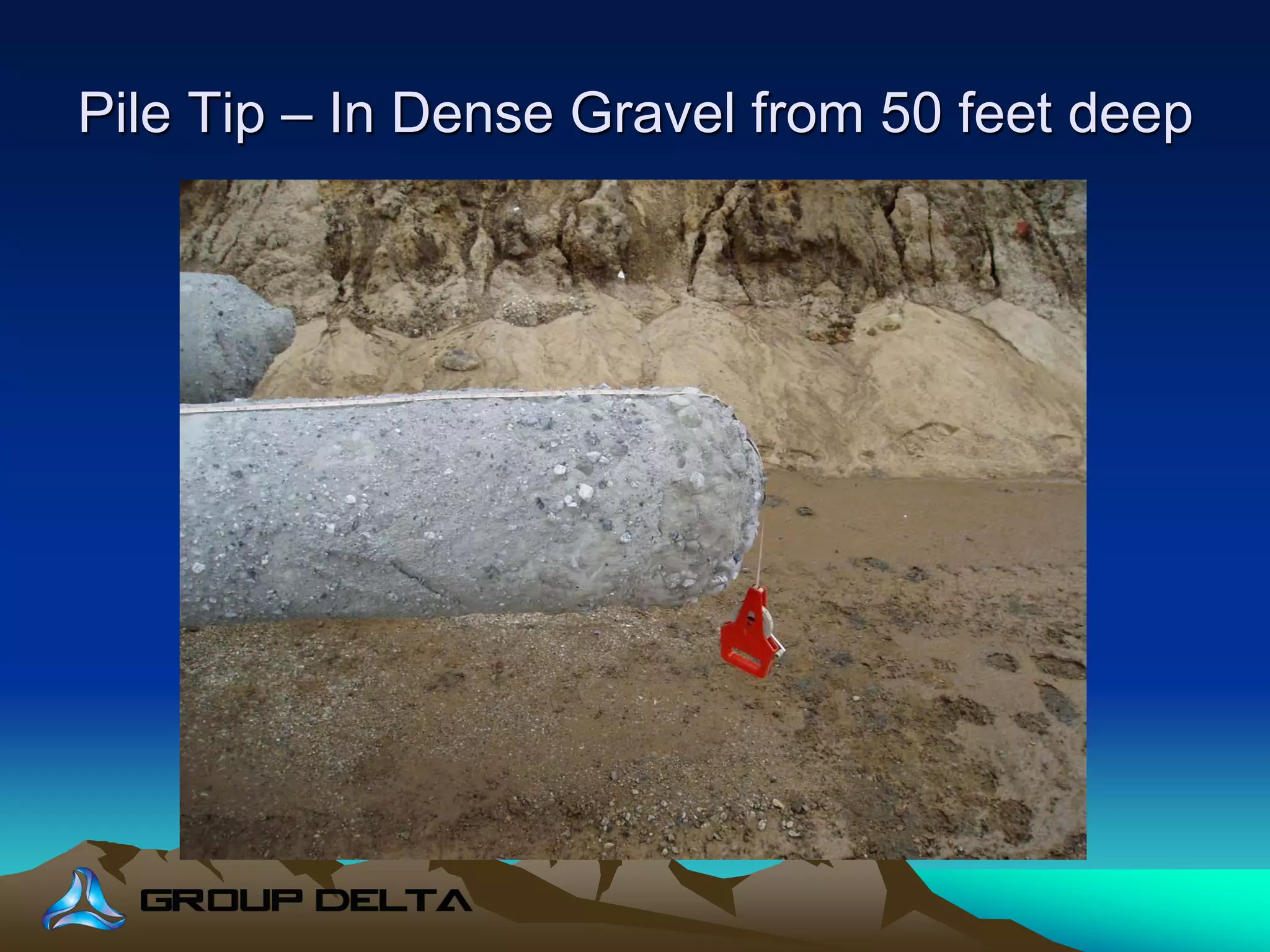

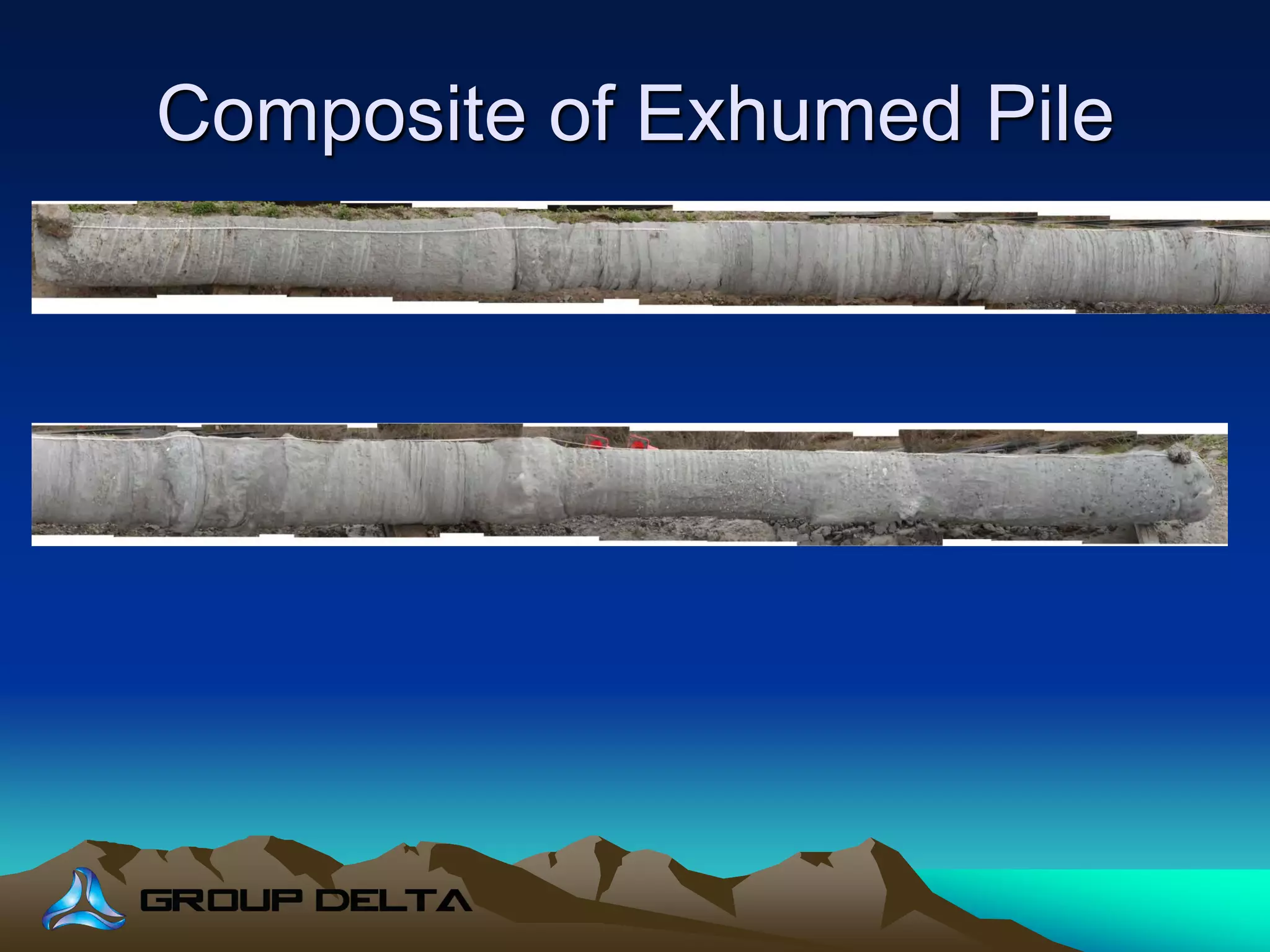

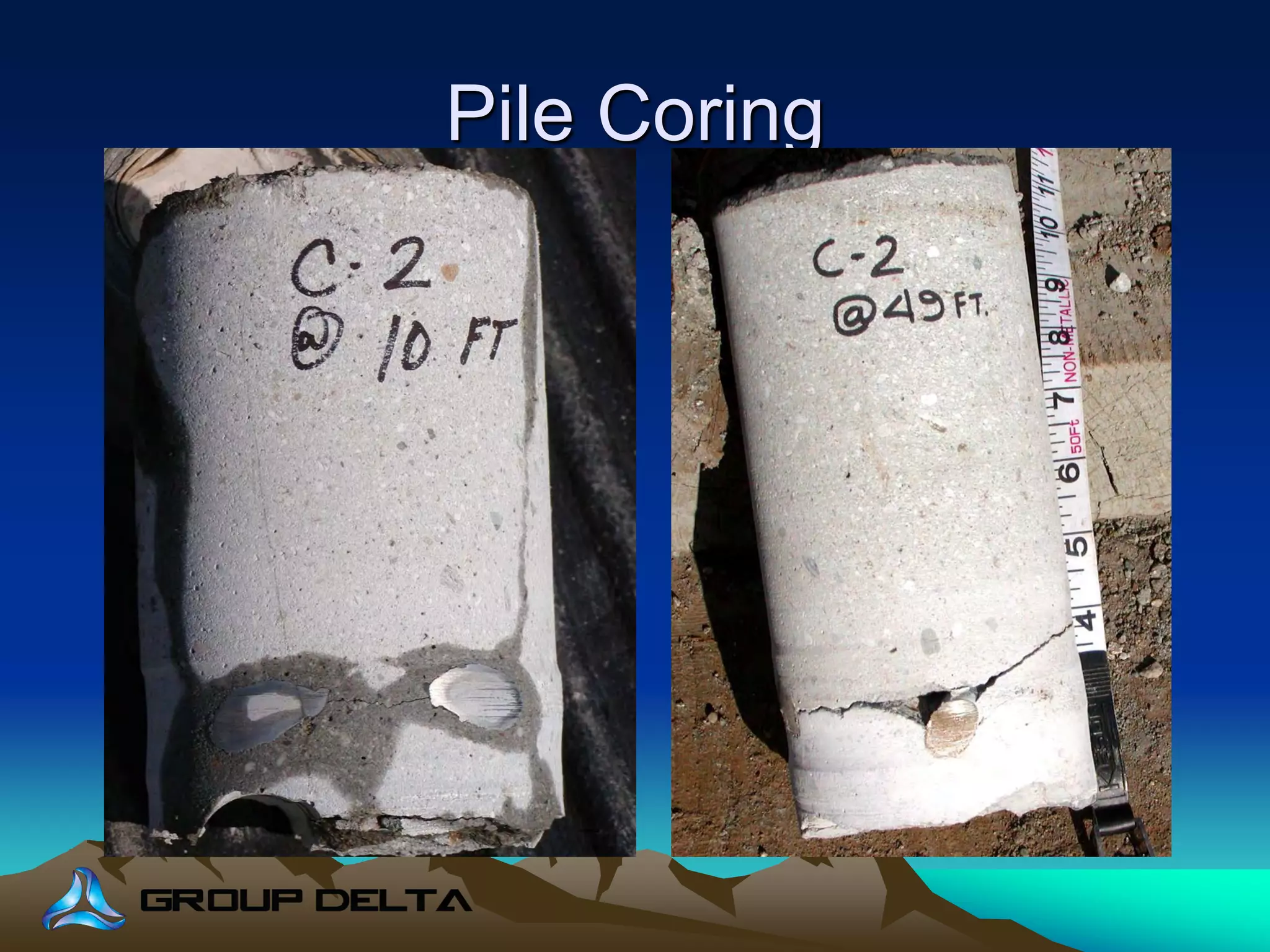

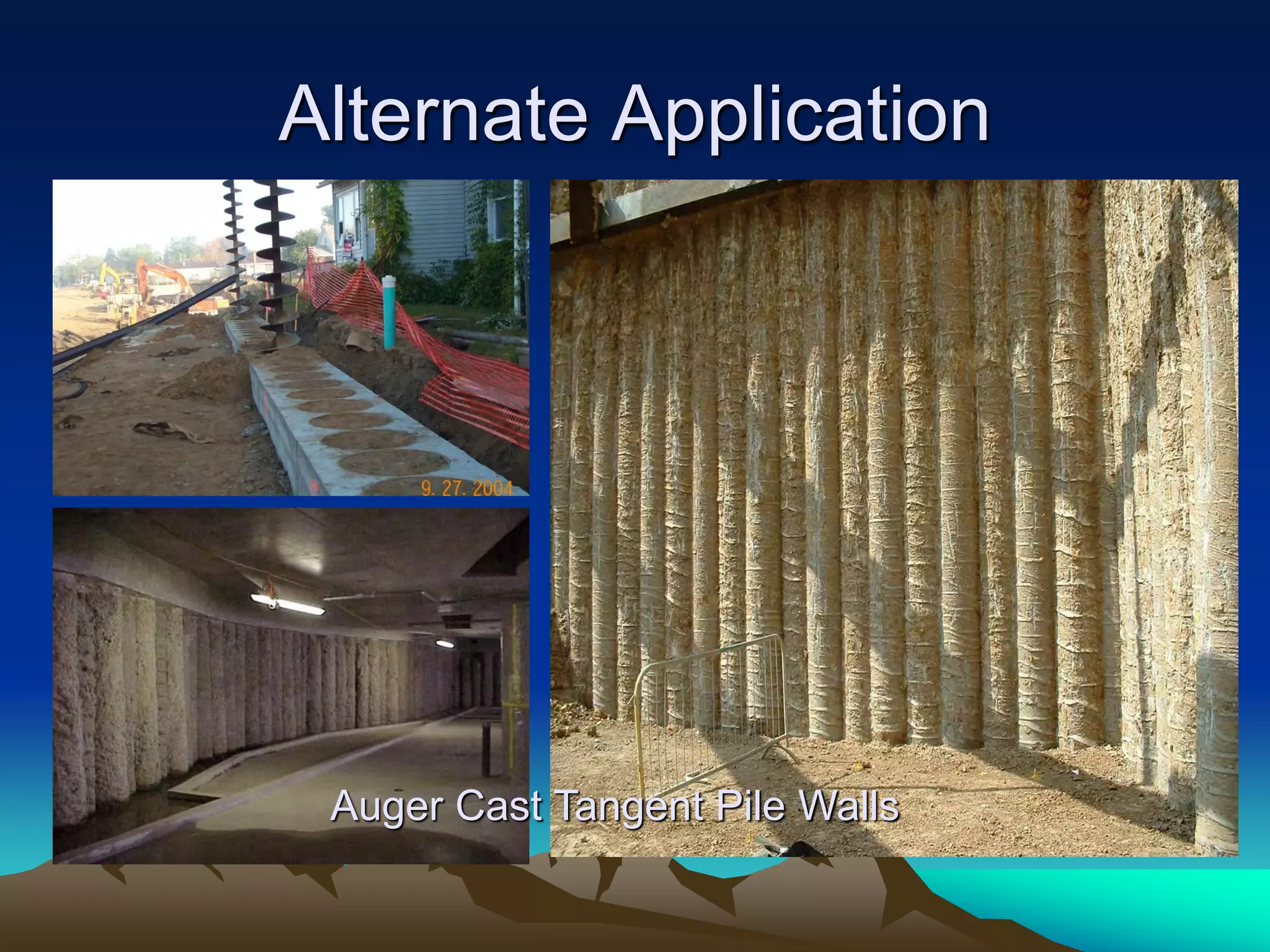

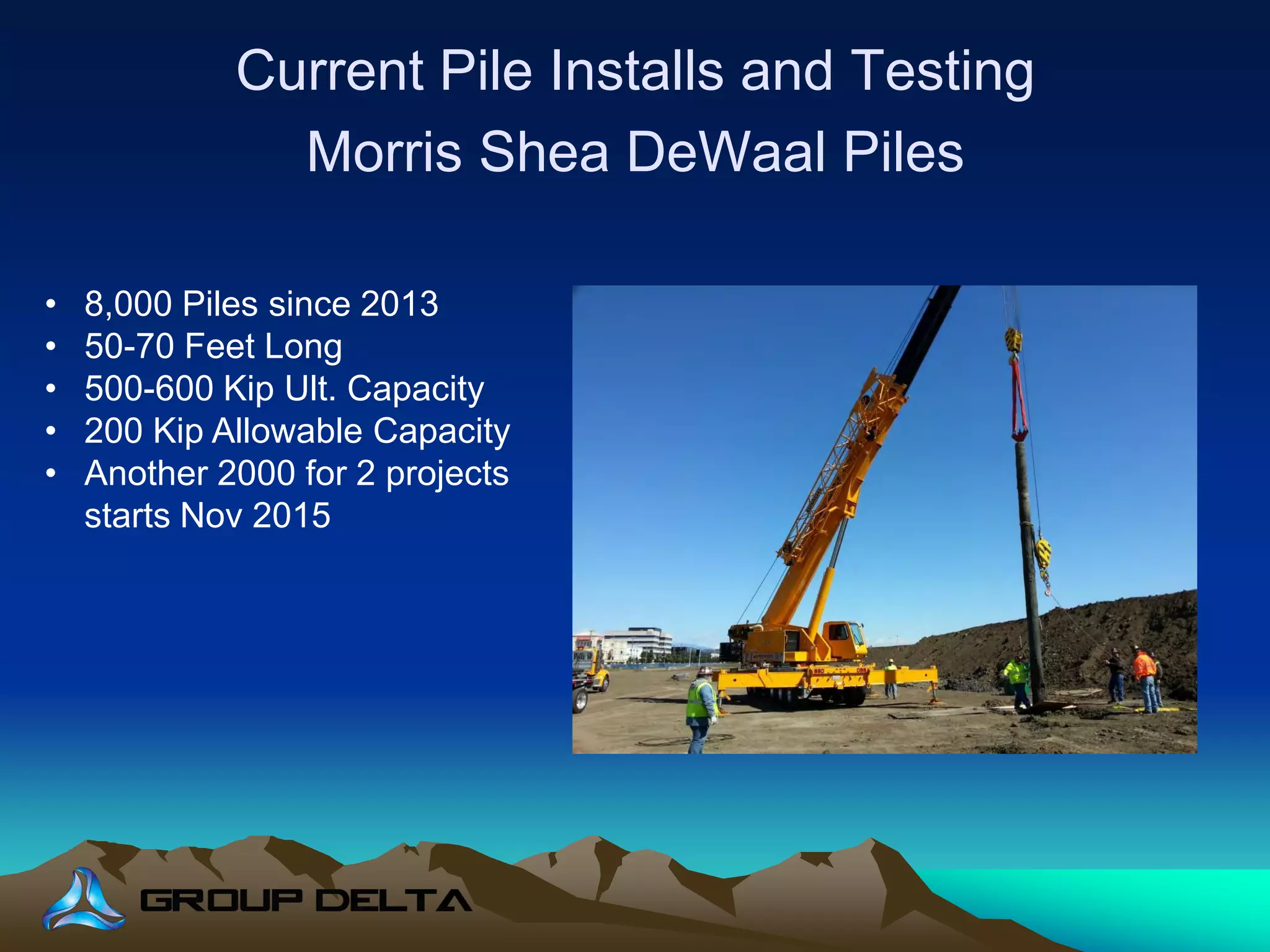

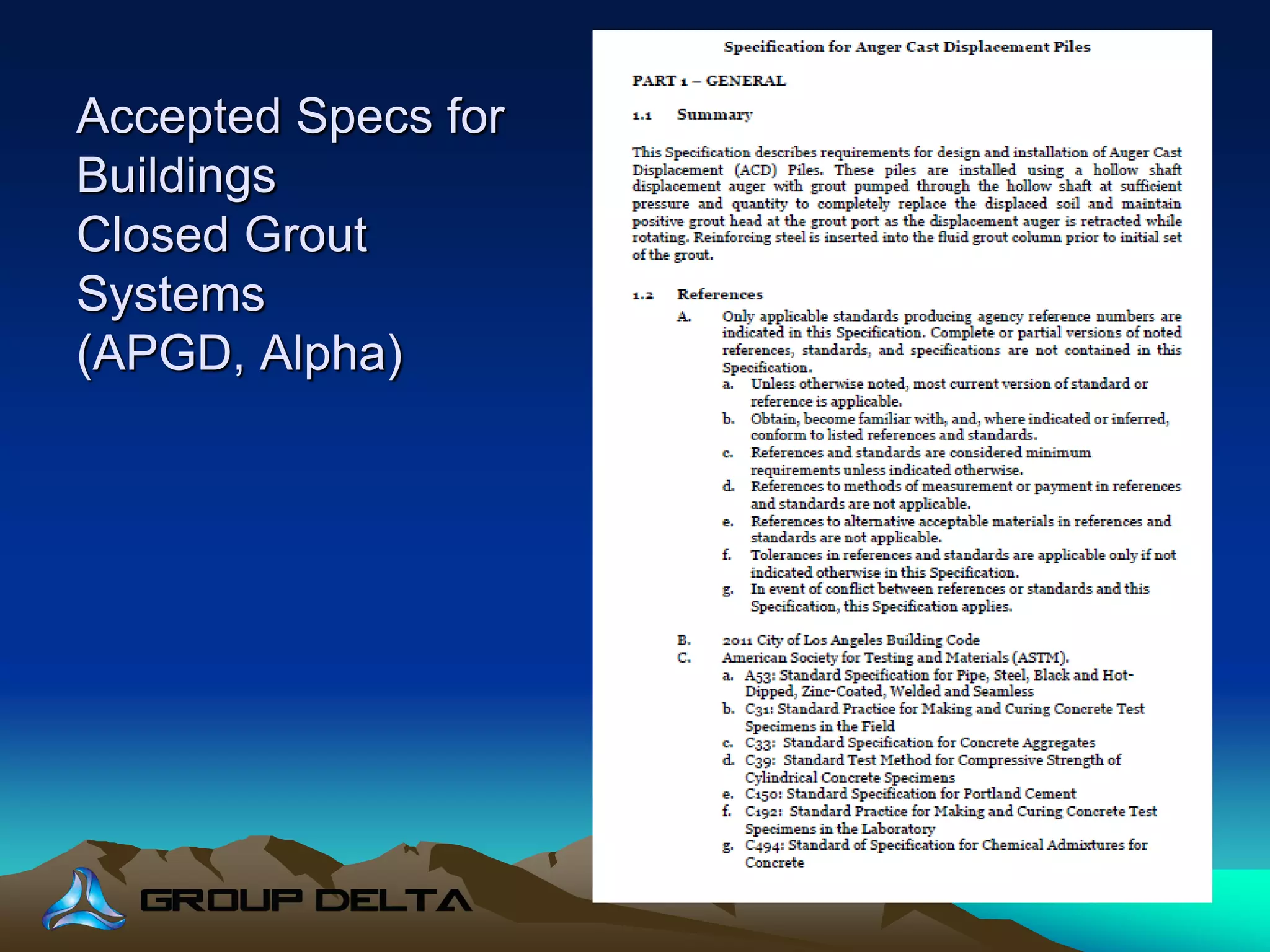

The document discusses recent trends in pile foundations, focusing on auger cast piles, particularly for projects with soft clay and high groundwater conditions in California. Nick Briffa of Delta Consultants presented various pile types, including auger cast and driven piles, and the importance of quality control for installation and load testing. Additionally, it covers the implementation of electronic monitoring for better project outcomes and highlights ongoing construction efforts using these technologies.