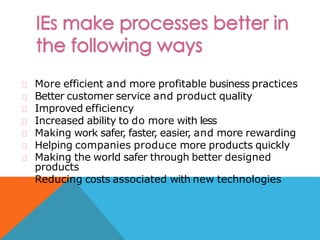

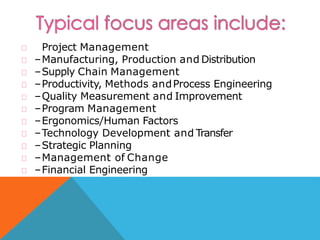

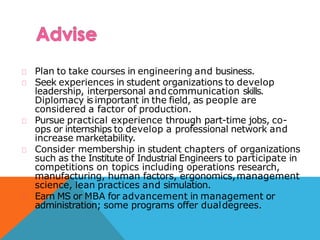

This presentation discusses the role of industrial engineers. Industrial engineers determine the most effective ways to use resources like people, machines, materials, information and energy to make products or provide services. They help companies by improving efficiency, productivity, quality and safety. The presentation outlines common industrial engineering roles and responsibilities like project management, manufacturing, supply chain management, and ergonomics. It provides examples of tasks such as managing suppliers, conducting audits, and facilitating process improvements. Finally, it discusses industries where industrial engineers work and advice for pursuing careers in the field.