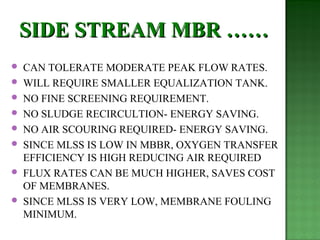

The document discusses Membrane Bioreactor (MBR) technology for sewage treatment. It explains that MBR uses a combination of biological treatment and ultrafiltration membranes. It compares submerged and side stream MBR configurations. Submerged MBR has higher energy costs due to higher membrane fouling, need for fine screening, and air scouring requirements. Side stream MBR separates biological treatment from membrane filtration, reducing fouling and energy costs by over 70%. The document promotes Indus Ecowater's side stream MBR system using MBBR biological treatment coupled with external ultrafiltration.