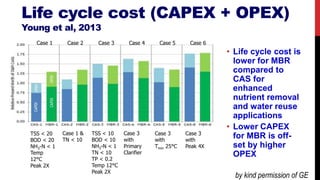

This document discusses various aspects of membrane bioreactor (MBR) technology in wastewater treatment, including design parameters, membrane characteristics, process configurations, and operational challenges. It highlights the cost-effectiveness of MBR systems compared to conventional treatments under specific conditions, while addressing technical issues such as fouling and energy consumption. Future developments in MBR technology aim at improving efficiency, reducing costs, and enhancing capabilities for water reuse.

![CAPEX, MBR vs oxidation ditch

Itokawa et al, 2014 (Japanese Sewage Works Agency)

0

200

400

600

800

1,000

1,200

1,400

1,600

1,800

2,000

0 2,000 4,000 6,000 8,000 10,000 12,000 14,000

Design capacity [m3

/d]

Constructioncost[103

JPY/(m3

/d)]

MBR (whole plant)

MBR (wastewater treatment)

OD plant

OD plant with sand filtration](https://image.slidesharecdn.com/ovivooperatorworkshopsessiond1s3-webready-150707132826-lva1-app6891/85/Simon-Judd-MBR-Low-Down-34-320.jpg)

![Specific energy demand, Japan

Itokawa et al, 2014 (Japanese Sewage Works Agency)

0

1

2

3

4

5

6

7

8

9

10

0 10 20 30 40 50 60 70 80 90 100

Inflow/capacity ratio [%]

Specificenergyconsumption[kWh/m3

]

Moryama

intermittent

operation](https://image.slidesharecdn.com/ovivooperatorworkshopsessiond1s3-webready-150707132826-lva1-app6891/85/Simon-Judd-MBR-Low-Down-36-320.jpg)