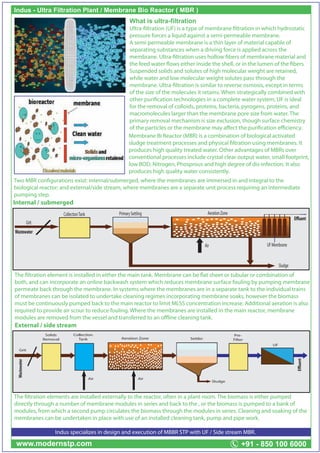

The document discusses the benefits of recycling treated sewage water. Recycling water reduces demand for fresh water, improves water supply reliability, and frees up water for the environment. Treated sewage can be used for non-potable purposes like gardening and toilet flushing through tertiary treatment processes like ultrafiltration and reverse osmosis to purify water to drinking standards. Ultrafiltration and membrane bioreactor systems are effective tertiary treatment technologies for recycling treated sewage water.