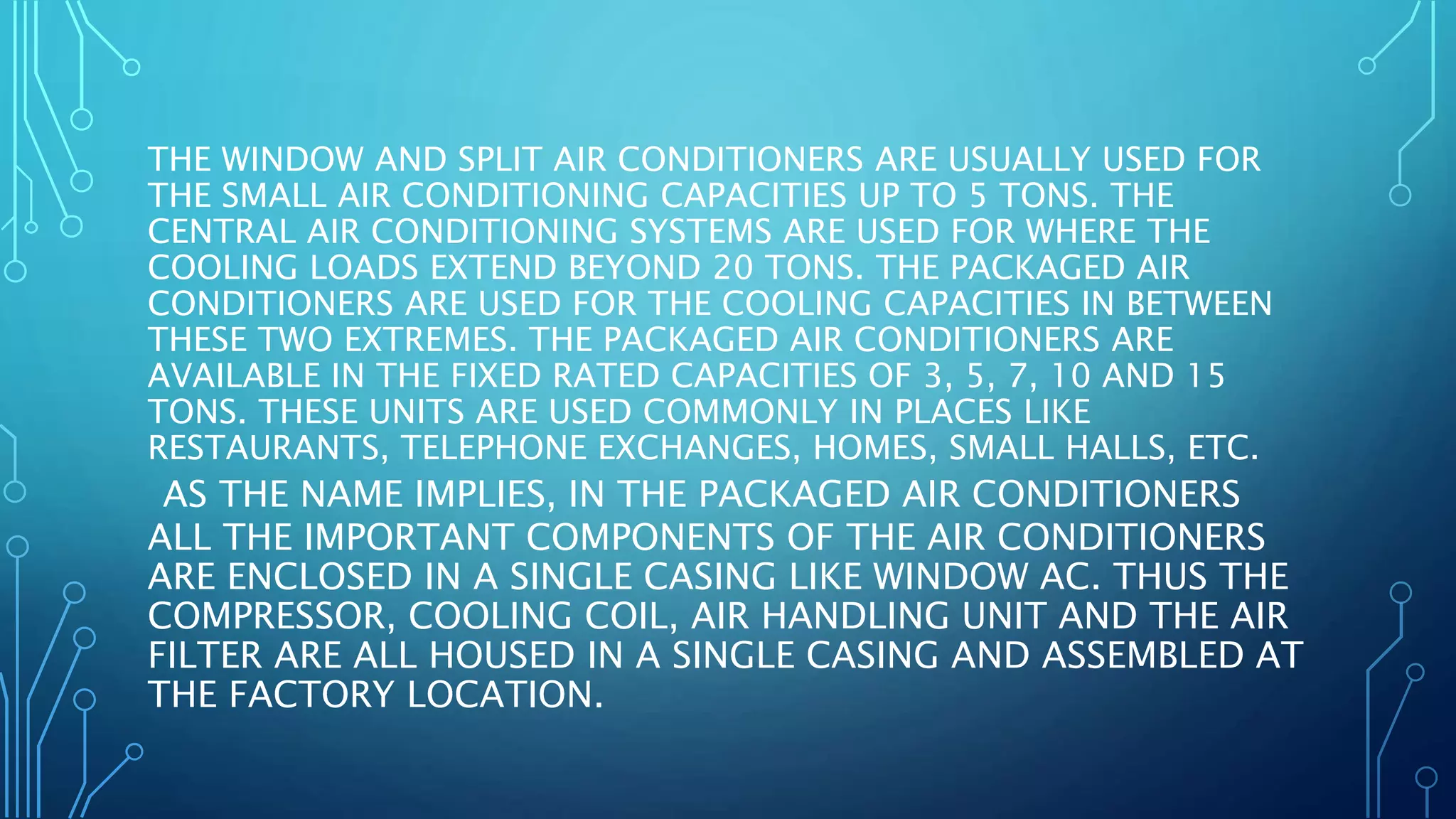

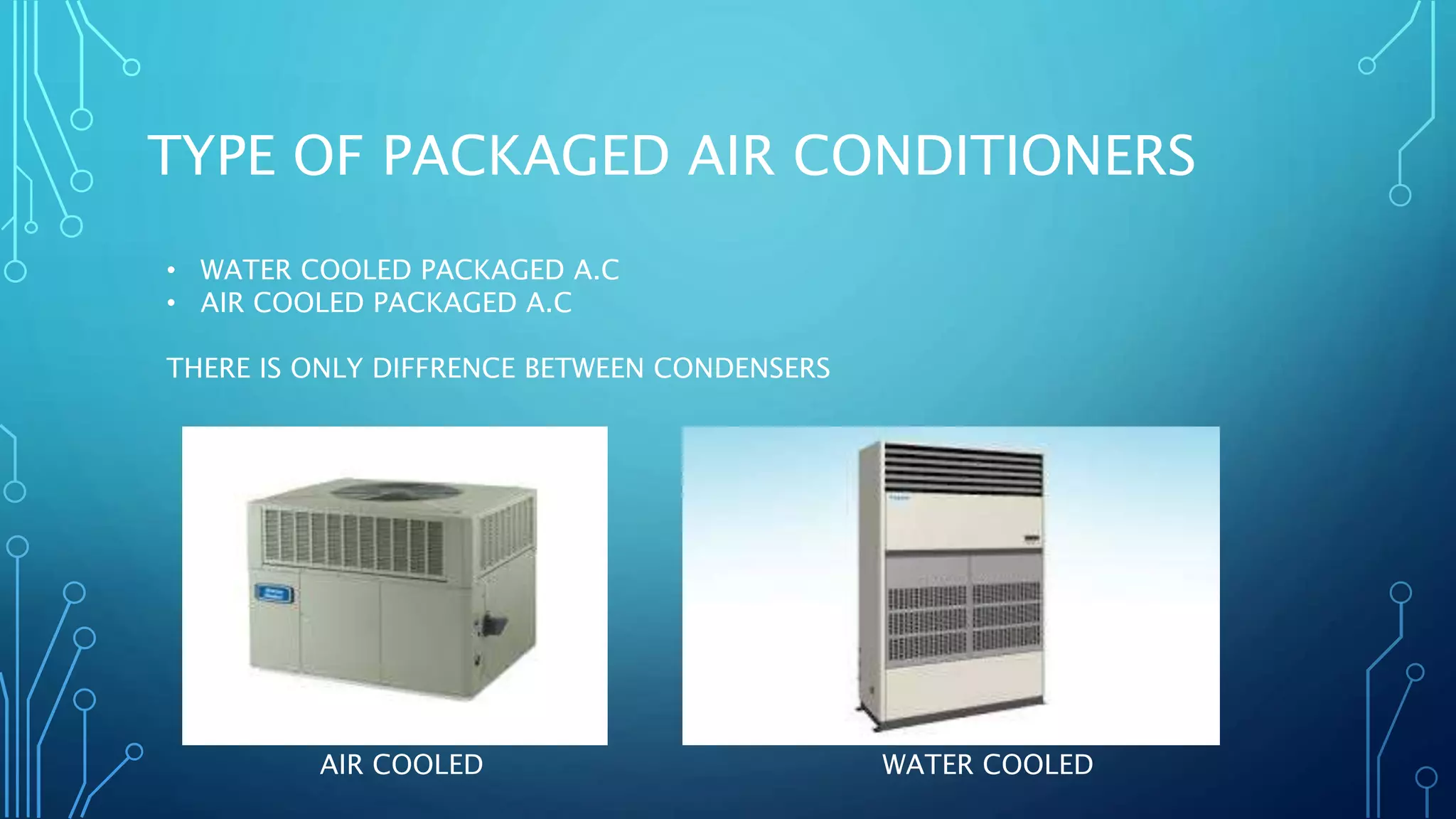

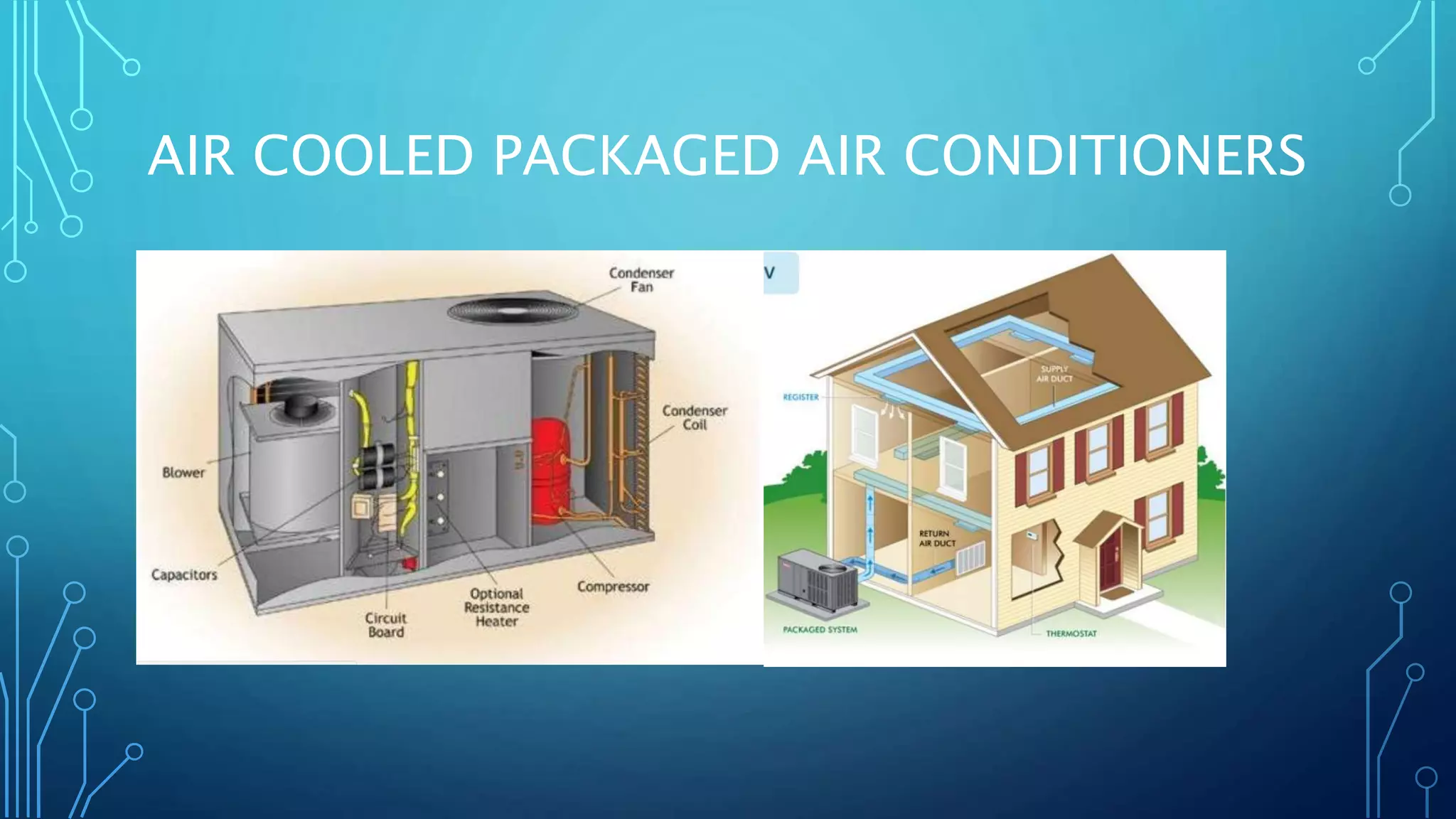

This document provides information about packaged air conditioners. It begins by defining a ton of refrigeration and providing an example calculation for selecting the appropriate size for a room. It then explains that packaged air conditioners are used for cooling capacities between 5-20 tons. The main components of packaged air conditioners, including the compressor, cooling coil, and air handling unit, are enclosed in a single casing. There are two main types - water cooled and air cooled - which only differ in their condenser type. Water cooled units use a shell and tube condenser cooled by water, while air cooled units use an outdoor condenser cooled by atmospheric air. The document concludes by listing some benefits of packaged air conditioners like space efficiency and quick

![SELECTION OF AIR CONDITIONER

• LET SIZE OF ROOM, HEIGHT = WIDTH = LENGTH = 10 FEET

THEREFOR, TON = [VOLUME OF ROOM ^1/3 ]/10

TON = [{(10)*(10)*(10)}^1/3]/10

= 10/10

= 1 TON](https://image.slidesharecdn.com/packagedairconditionersautosaved-191121215142/75/Packaged-air-conditioners-3-2048.jpg)