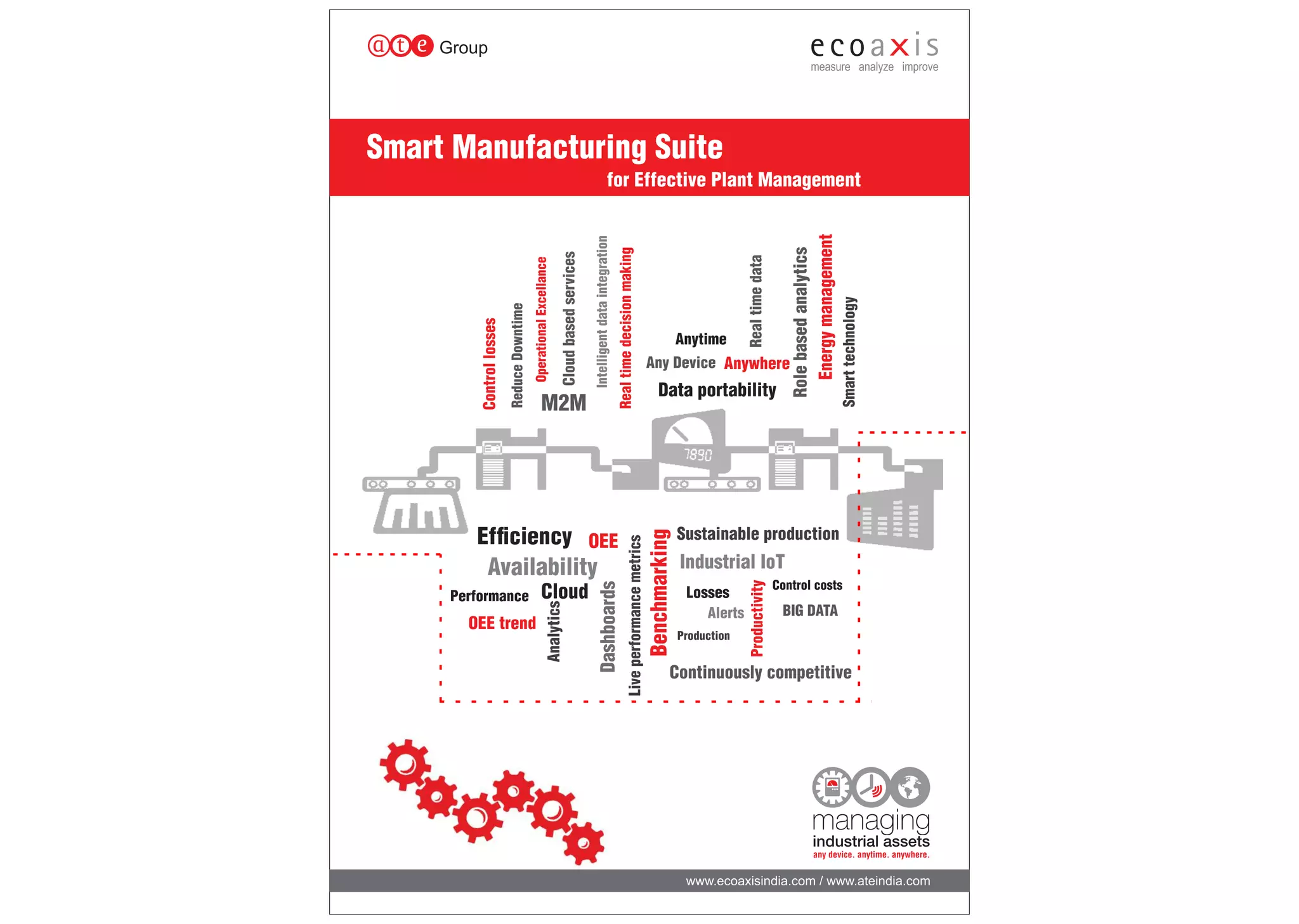

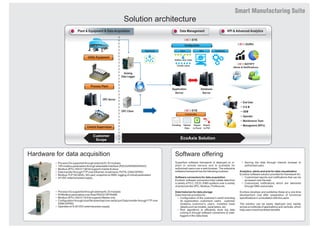

The document describes a smart manufacturing suite called SUPERAxis developed by A.T.E. Enterprises to provide real-time plant monitoring and analytics. The suite involves continuous monitoring of remote plant assets and critical process parameters. It provides real-time reporting of KPIs and alerts to keep plant users informed of critical conditions. The solution includes hardware for data acquisition and a software framework for data storage, visualization of trends, reports, alerts and notifications to empower plant personnel.