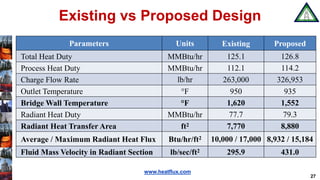

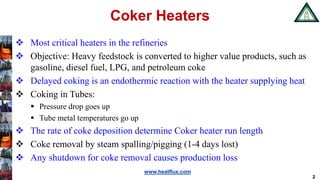

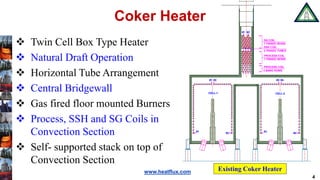

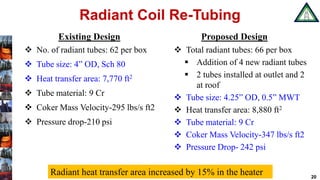

The document discusses improvements to coker heaters critical for converting heavy feedstock in refineries to valuable products like gasoline and diesel fuel. It outlines design parameters, operating issues, and proposes a new radiant coil re-tubing design to enhance performance and reduce overheating. Future upgrades to the convection section are suggested to further optimize heater efficiency in a planned revamping around 2026.

![www.heatflux.com

Flue Gas Flow and Temperature Profile

9

Higher

velocity flue

gas is

observed on

the inner side

Higher flue

gas

temperature

observed near

the inner cell

tubes

Existing Design

[°F]

[ft/s]](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-9-320.jpg)

![www.heatflux.com

Radiant Heat Flux Profile

10

Radiant heat flux for

inner cell tubes is

higher as compared to

the outer cell tubes

Existing Design

Inner Tubes Outer Tubes

[Btu/hr.ft2]](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-10-320.jpg)

![www.heatflux.com

Flue Gas Temperature around Tubes

11

[°F]

Inner Tubes Outer Tubes

Flue gas temperatures around

inner cell tubes and outer cell

tubes are significantly

different

Existing Design](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-11-320.jpg)

![www.heatflux.com

[°F]

Flue Gas Flow and Temperature Profile

12

High flue gas temperature and

velocity is reduced for the inner

tubes

Existing Operating[ft/s]](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-12-320.jpg)

![www.heatflux.com

Radiant Heat Flux

13

Inner Tubes Outer Tubes

Radiant heat flux is

similar for inner and

outer tubes for

operating case

Existing Operating

[Btu/hr.ft2]](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-13-320.jpg)

![www.heatflux.com

Flue Gas Temperature around Tubes

Inner Tubes

Existing Operating

[°F]

Outer Tubes

Clearly, the difference in

flue gas temperatures around

inner and outer cell tubes

have reduced significantly as

compared to the design case

This reduction is because

inner cells were fired at 30%

lower firing rate than outer

cells

14](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-14-320.jpg)

![www.heatflux.com

Flue Gas Temperature Profile

17

Operating Case

For operating case flue

gas temperature in the

inner cell has reduced

[°F]

Design Case](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-17-320.jpg)

![www.heatflux.com

Radiant Heat Flux Profile

18

Design Case Operating Case

Radiant tubes heat flux

for inner tubes has

been reduced for the

operating case

[Btu/hr.ft2]](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-18-320.jpg)

![www.heatflux.com

Velocity Vectors

Flue gas velocity near inner

tubes is very high and getting

deflected downward

Flue gas velocity is shifted

downward with addition of baffle

Roof tubes are away from flue gas

Adding refractory baffle at the top further improves the flue gas recirculation pattern

Existing Proposed Case with

Baffle

Proposed Case

[ft/s]](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-23-320.jpg)

![www.heatflux.com

Flue Gas Temperature Contours

Addition of refractory baffle further increased the distance of hot flue gas with

respect to roof tubes

High temperature flue gas is

touching the inner roof tubes

Shifting roof tubes reduces chances of

flame impingement / coking issues

24

[°F]

Existing Proposed Case with

Baffle

Proposed Case](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-24-320.jpg)

![www.heatflux.com

Radiant Tube Heat Flux (Arch)

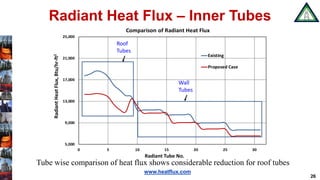

Maximum heat flux on roof tubes is reduced by ~4,200 Btu/hr.ft2

Proposed Case

Heat Flux 18,651 Btu/hr.ft2 Heat Flux 14,443 Btu/hr.ft2

Existing

25

[Btu/hr.ft2]](https://image.slidesharecdn.com/afrc-improvingperformanceofcokerheatersrev-200415172449/85/Improving-Performance-of-Coker-Heaters-25-320.jpg)