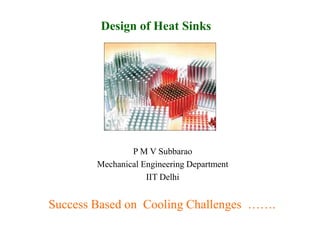

This document discusses the design of heat sinks for semiconductor devices. It describes the evolution of heat sink designs from simple uniform designs in the early 1990s to more complex designs with features like short fins, longitudinal fins, and combined pin fins to improve convection cooling. The key factors in heat sink design are thermal conductivity, cooling surface area, material and manufacturing costs. Designs must consider parameters like air temperature, velocity, duct size, and power dissipation. Optimization of factors like fin geometry, number of fins, and base thickness can improve thermal performance while meeting other constraints.