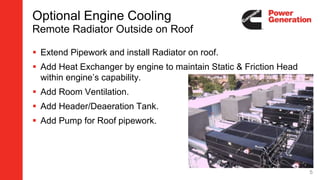

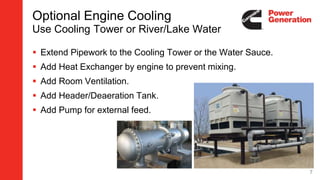

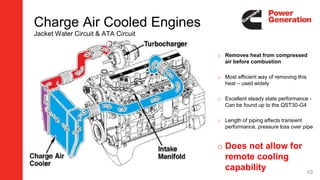

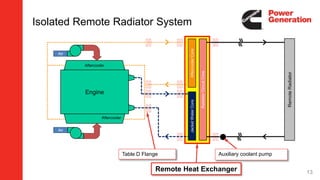

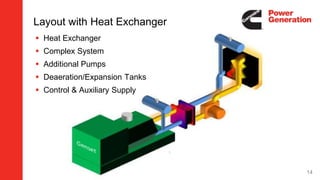

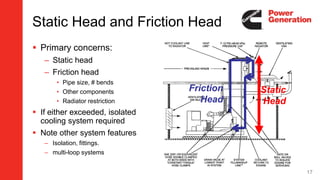

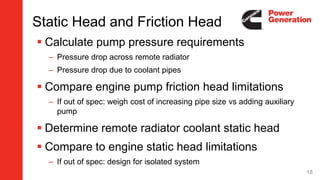

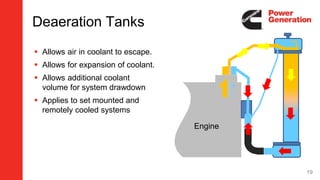

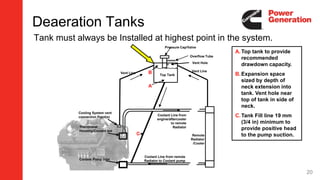

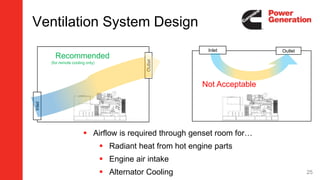

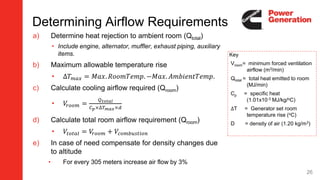

This document discusses various remote cooling configurations for engine cooling systems. It covers extending pipework to remote radiators located inside or outside the engine room, on the roof, or connected to building chillers, cooling towers, or other external water sources. Key considerations include static head, friction head, heat exchangers, deaeration tanks, ventilation, and ensuring the remote system does not exceed the engine cooling pump's capabilities. Different cooling system types like charge air cooled, single pump single loop, and dual pump dual loop are also reviewed.