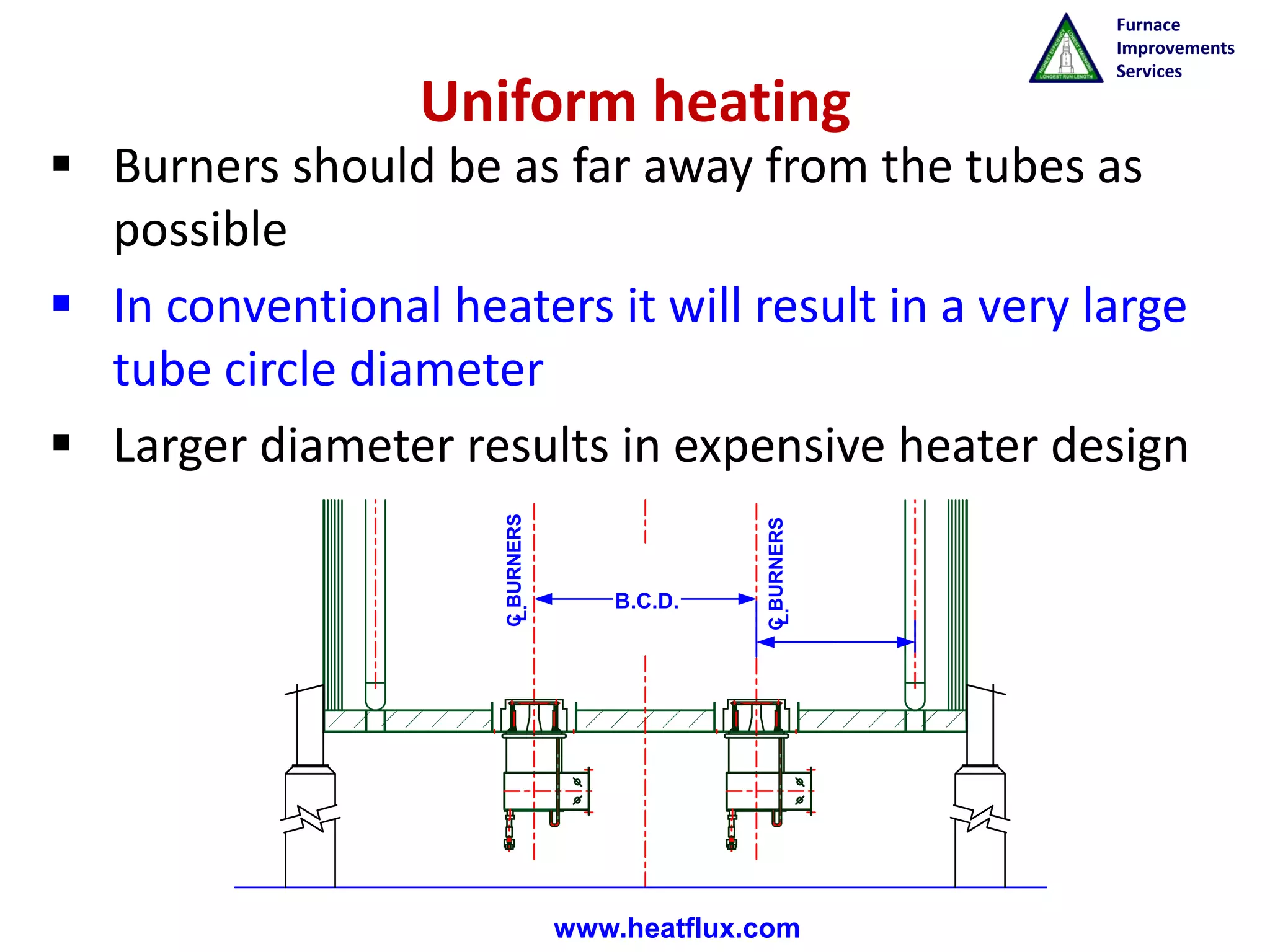

The document provides a comprehensive overview of furnace improvement services, highlighting technologies such as inclined burner firing systems that enhance heat transfer and operational efficiency. It covers various designs, including vertical cylindrical heaters and options for low NOx burners, showcasing benefits like reduced tube metal temperatures and uniform heating. Additionally, it details specific case studies demonstrating improvements in thermal performance across multiple heater configurations.

![Furnace

Improvements

Services

www.heatflux.com

Flue Gas Velocity Contours

Y-Plane

[ft/s]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-18-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Flue Gas Vector Plot

Long recirculation is observed.

Y-Plane

[ft/s]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-19-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Flame Contours (CO >2000 ppm)

Colored by Temperature (o F)

[°F]

Flame shapes are separate from each other.

[°F]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-20-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Flame Contours (CO >2000 ppm)

Colored by height (ft)

[ft]

[ft]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-21-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Tube Metal Temperature Contours

Wall Tubes

Tube Metal Temperatures Flue Gas Temperatures near Tubes

[°F] [°F]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-22-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Wall Tubes Heat Flux Contours

Average Heat Flux on

the Tubes: 10,482

Btu/hr∙ft2

[Btu/hr∙ft2]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-23-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Flue Gas Temperature Contours

Central Plane

[°F]

Temperature

near the

tube is high.

Flame angled

towards the center of

the furnace / away

from tubes.

Existing Case Proposed Modification](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-28-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Flue Gas Temperature Contours

Plane

Location

Existing Case Proposed Modification

Temperature

near the tube

is high.

[°F]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-29-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Fluid Path Lines: from Fuel Inlet

Existing Case Proposed Modification

Outer

recirculation

pattern

[ft/s]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-30-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Tube Metal Temperatures

[°F]

Existing Case Proposed Modification

Hot spots due

to flame

impingement.

TMTs more

uniform.](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-31-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Radiant Tube Heat Flux

High heat flux

distribution at

bottom of the

tubes

Existing Case Proposed Modification

[Btu/hr∙ft2]

[Btu/hr∙ft2]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-32-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Velocity Vectors

Base Case vs Inclined Firing System

www.heatflu

40

0 ft

Height in

Feet

19 ft

36 ft

50 ft

[ft/sec]

Existing Case

with Vertically Fired

Burners

Proposed Case

with Inclined Firing

System](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-40-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Temperature Contours

Base vs Inclined Firing System

Base Case Inclined Firing System

www.heatflu

41

[°F]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-41-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Temperature Contours at 10ft

Base Case vs Inclined Firing System

Base Case Inclined Firing System

At 10 ft At 10 ft

www.heatflu

42

[°F]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-42-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Temperature Contours at 15 ft -

Base Case vs Inclined Firing System

Base Case Inclined Firing System

1

At 15 ft At 15 ft

www.heatflu

43

[°F]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-43-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

CO Mass Fraction Contours at 10 ft

Base Case vs Inclined Firing System

At 10 ft

Inclined Firing SystemBase Case

At 10 ft

www.heatflu

44

[ppm]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-44-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

CO Mass Fraction Contours at 15 ft

Base Case vs Inclined Firing System

At 15 Ft

Inclined Firing SystemBase Case

At 15 Ft.

www.heatflu

45

[ppm]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-45-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Iso Surface of CO MF 2000 PPM Colored

by Temperatures Base Case vs Inclined Firing

System

Base Case Inclined Firing System

Top View

46

[°F] [°F]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-46-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Iso Surface of CO Mass Fraction

2000 ppm Colored by Flame Height

Base Case Inclined Firing

System

www.heatflu

47

[ft]](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-47-2048.jpg)

![Furnace

Improvements

Services

www.heatflux.com

Radiant Wall Temperatures

Base Design Proposed Design

For h =100 Btu/ft2∙h

and T= 800 °F

www.heatflu

48

[°F]

FIS Patented

Technology](https://image.slidesharecdn.com/uniformheattransferinfiredheatersslideshare-150225162108-conversion-gate01/75/Uniform-heat-transfer-in-fired-heaters-48-2048.jpg)