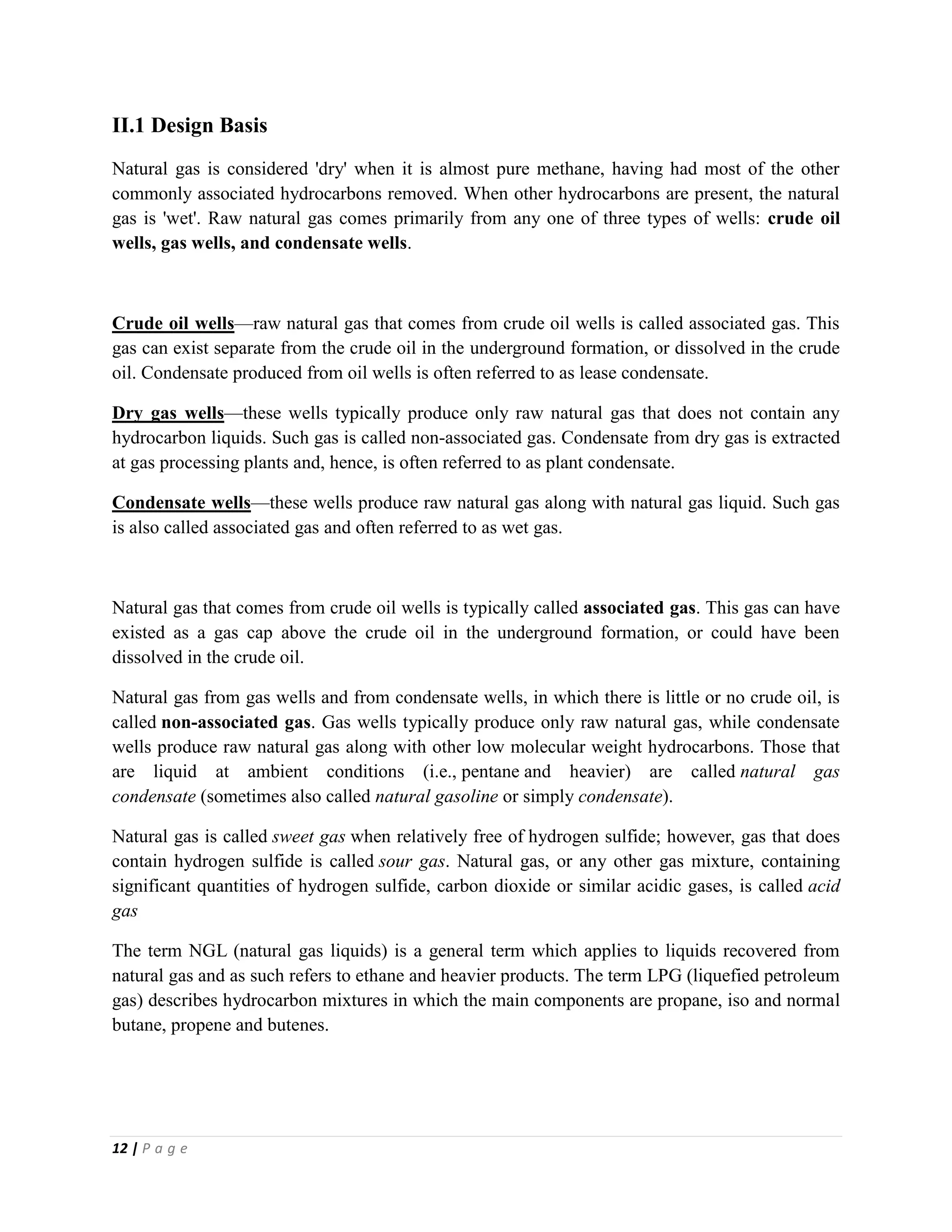

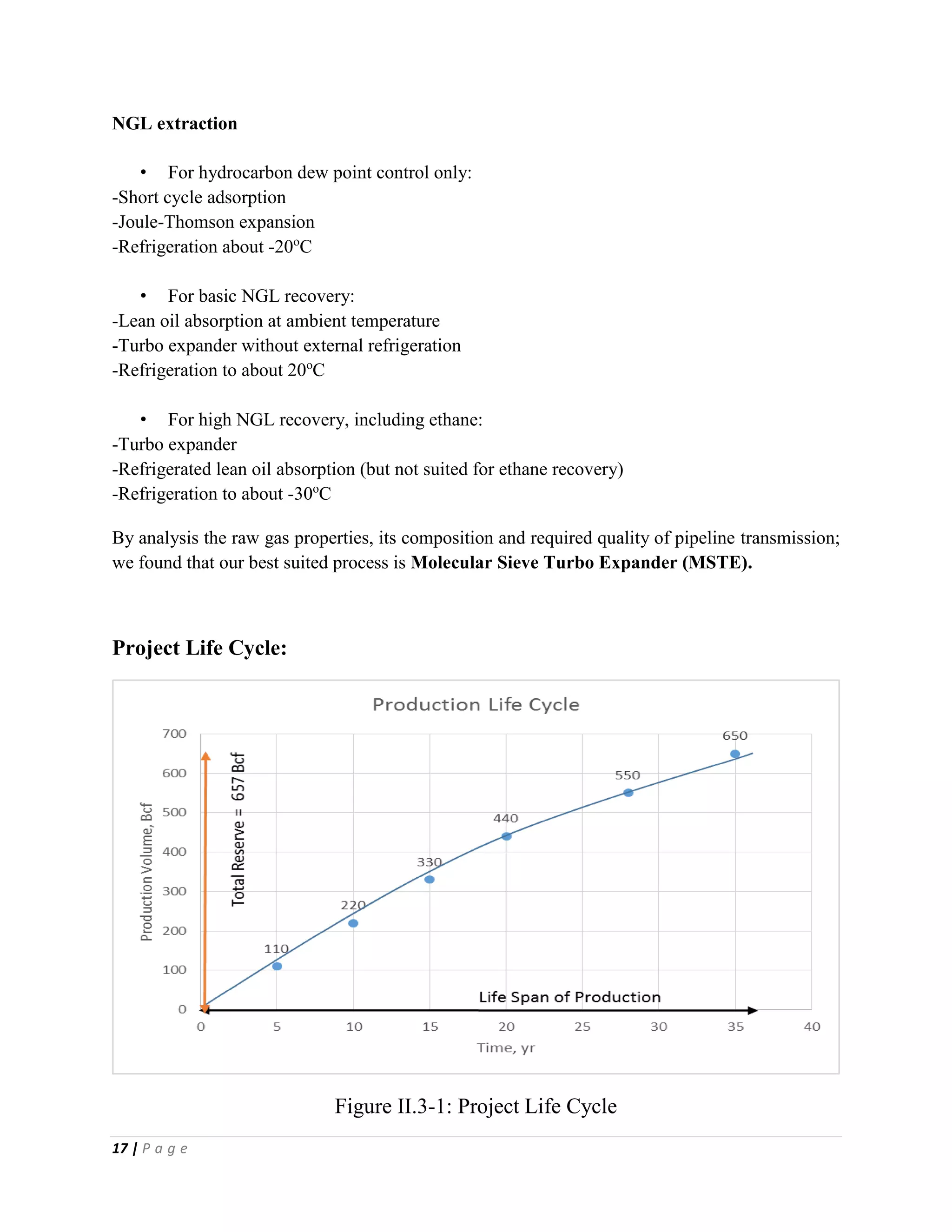

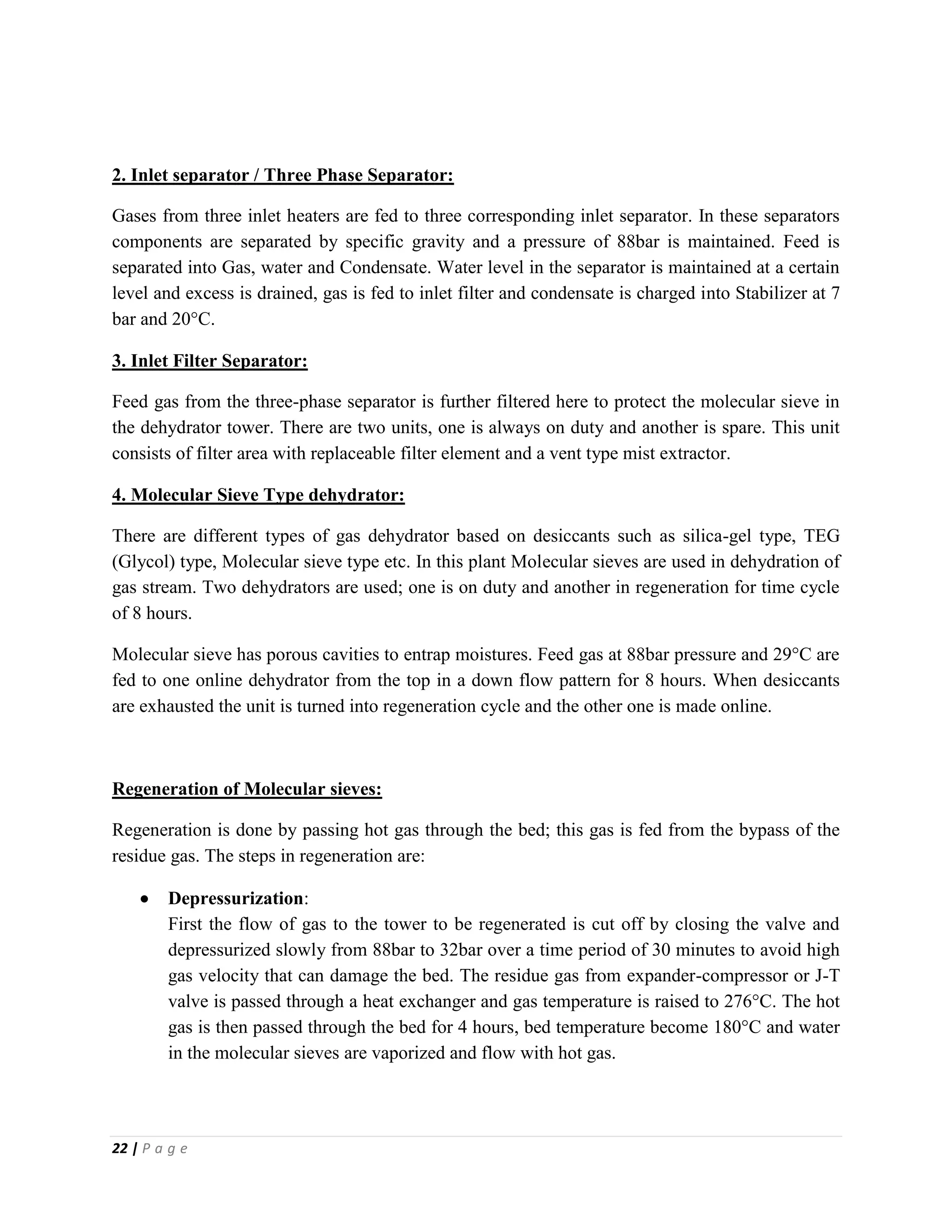

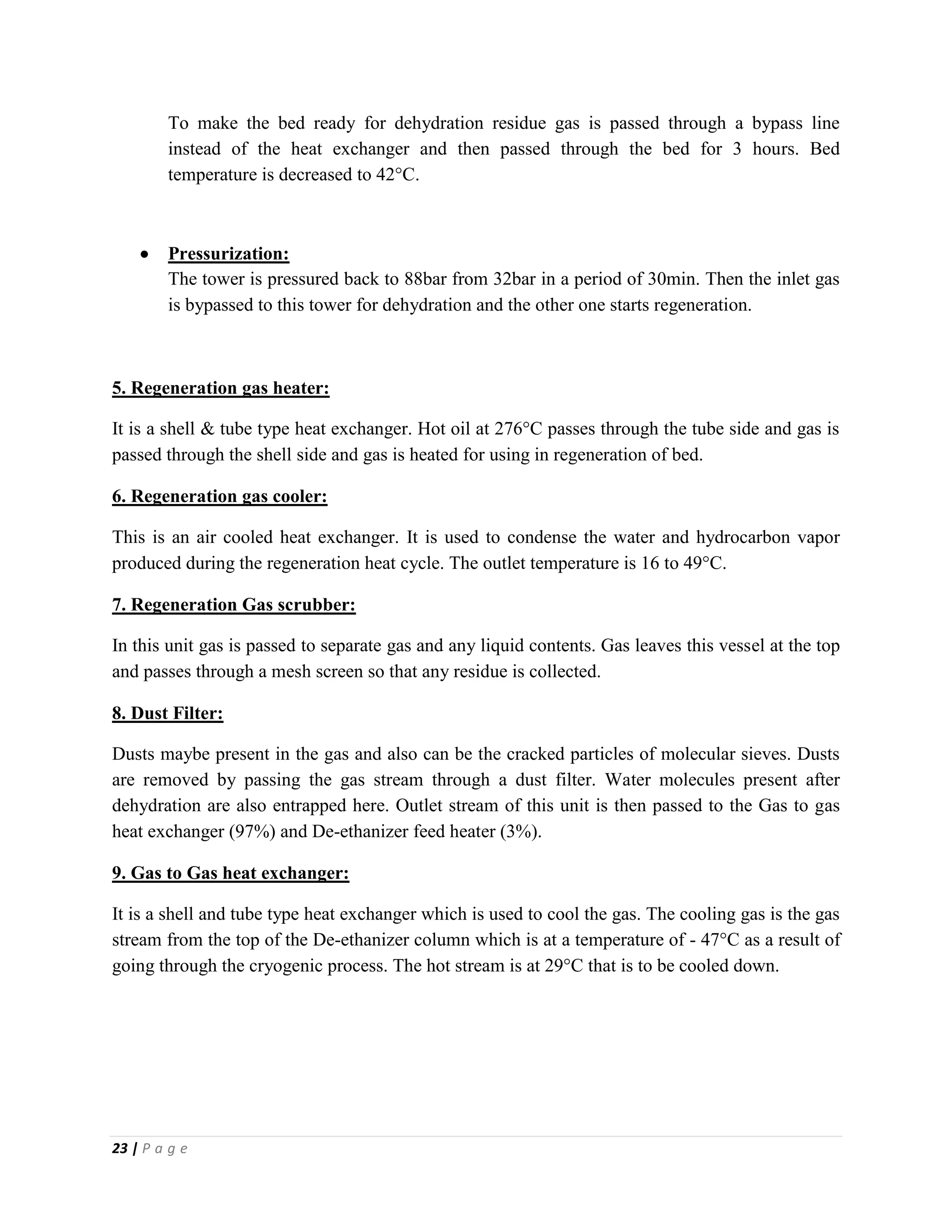

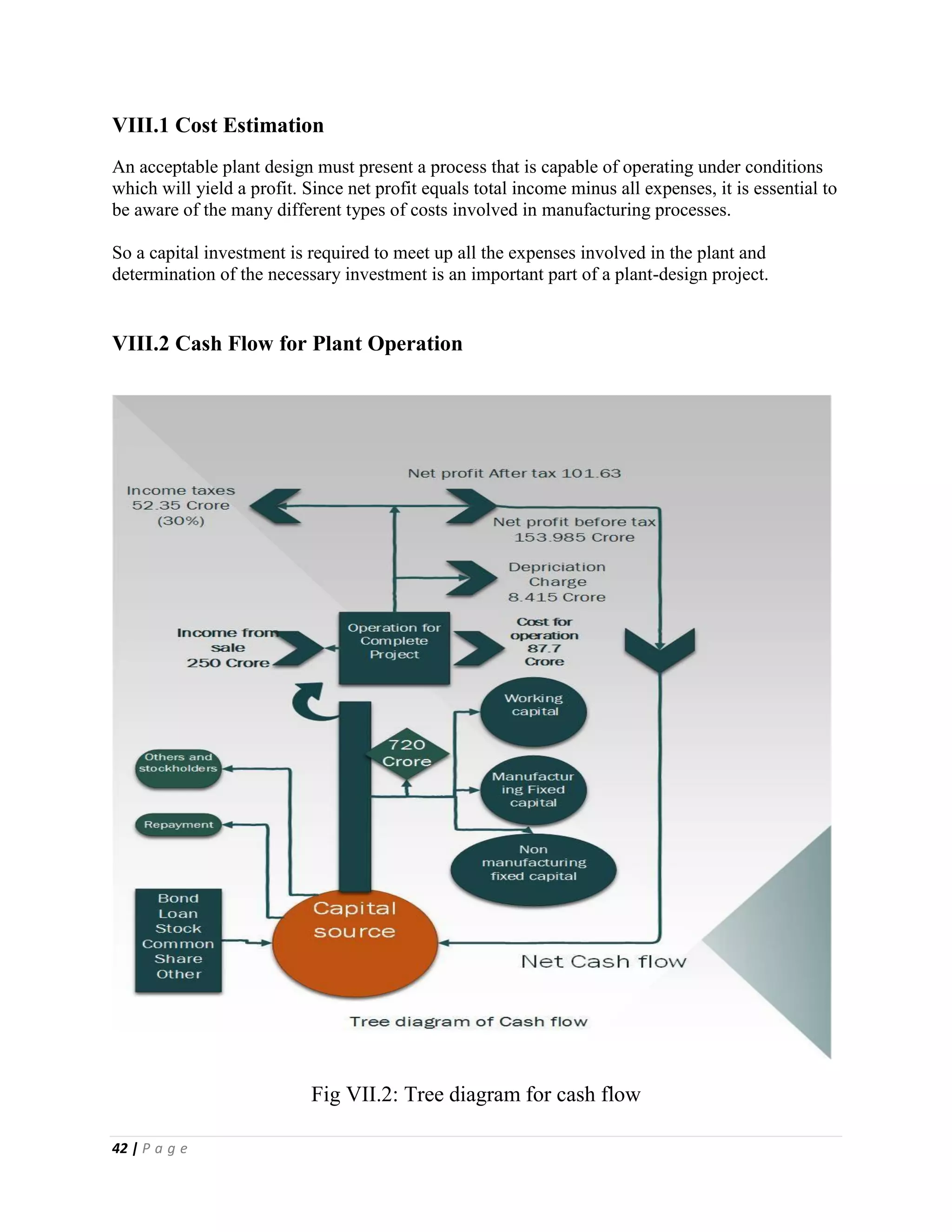

This document provides information about the design basis and process selection for a natural gas processing plant located in Kailashtilla, Sylhet, Bangladesh. The plant will process raw natural gas from wells with a maximum production capacity of 90 MMcfd and current production of 60 MMcfd. Key decisions include selecting Joule-Thomson expansion and a turbo-expander for cryogenic processing to extract natural gas liquids. For dehydration, molecular sieves will be used due to their high capacity and ability to reduce water content to below 0.1 ppm. Several processes were considered and compared for natural gas dehydration and NGL extraction based on factors like efficiency, cost, and operability.