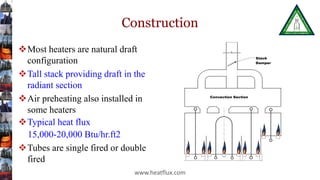

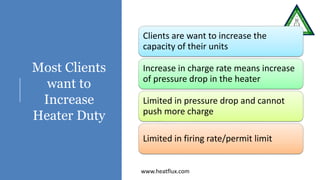

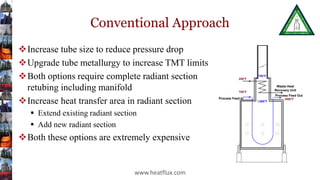

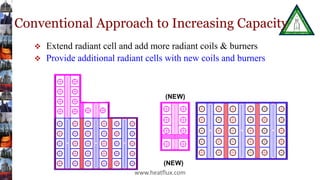

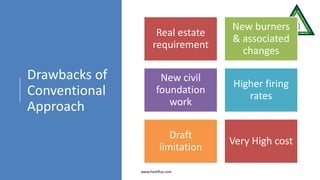

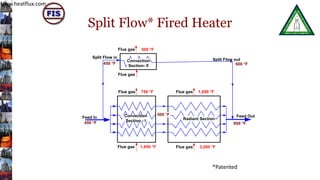

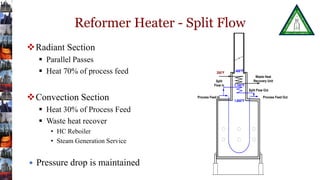

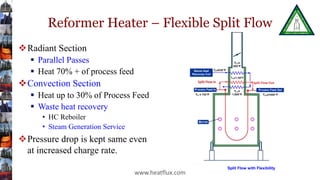

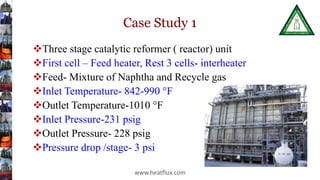

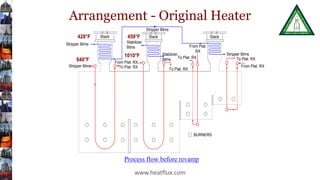

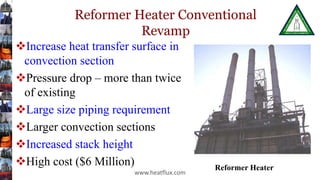

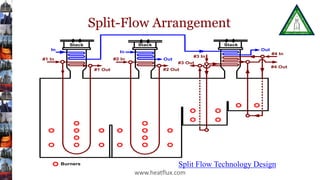

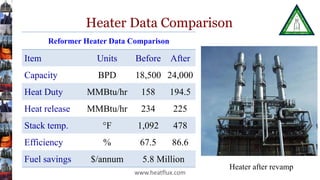

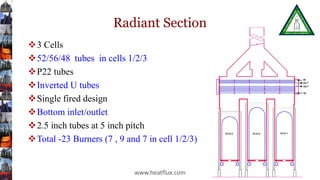

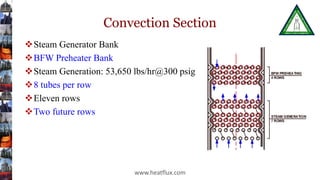

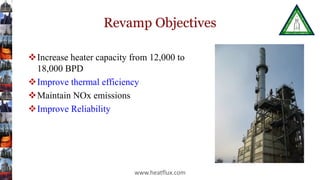

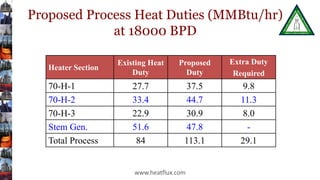

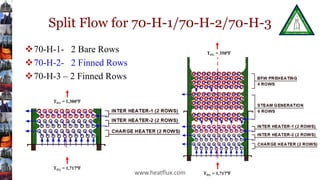

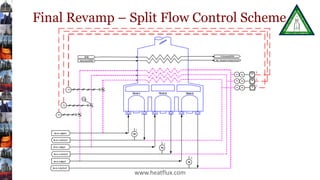

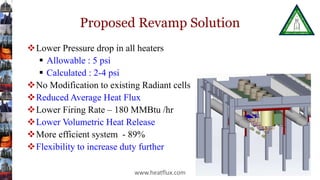

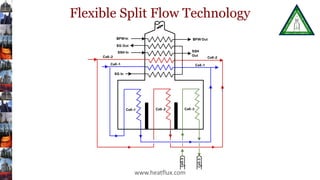

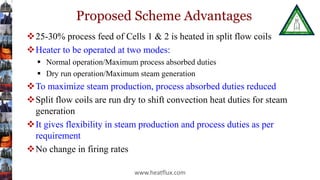

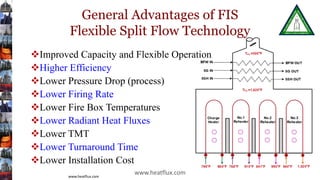

The document discusses advancements in catalytic reformer heaters, emphasizing the use of split flow technology to enhance refinery operations while maintaining lower pressure drops and costs. It outlines conventional approaches to increasing capacity and highlights the drawbacks, advocating for flexible split flow technology as a more efficient and cost-effective solution. Two case studies illustrate the efficiency and capacity improvements achieved through this new method.