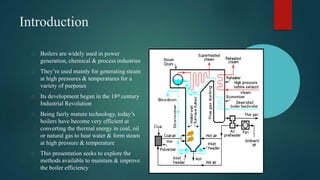

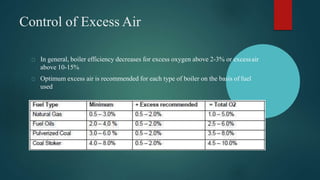

This document discusses methods for improving boiler availability and efficiency. It outlines that combustion management through proper draft and air-fuel mixture control, feedwater management through condensate recovery, and steam distribution management through optimal piping design and insulation are the main areas for improvement. Maintaining high combustion efficiency requires burning fuel completely with minimal excess air while extracting maximum heat from combustion gases. Feedwater contaminants are reduced through condensate recovery to decrease makeup water. Steam distribution needs properly sized and insulated piping to minimize heat loss along with regular maintenance of steam traps and other components.