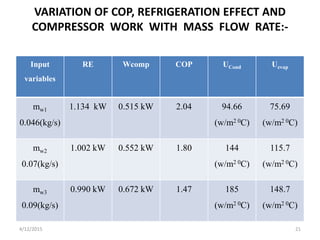

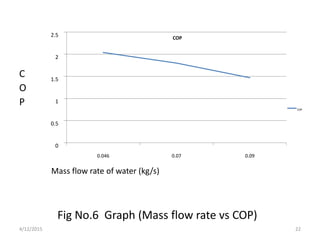

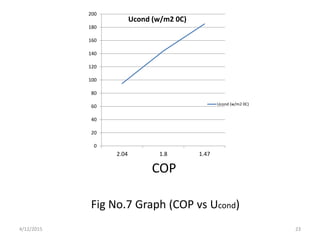

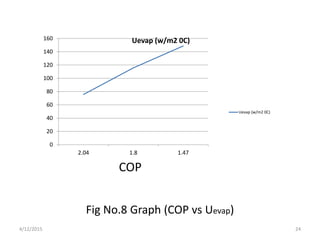

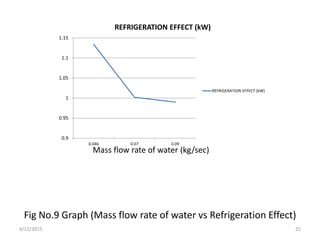

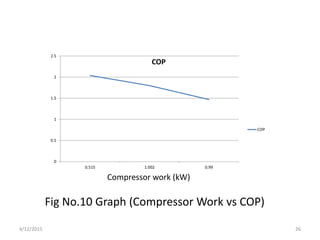

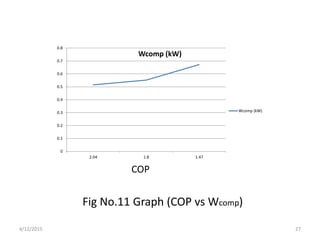

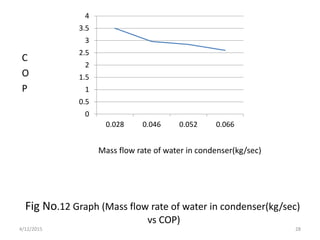

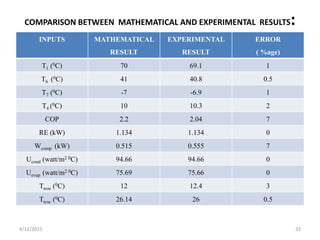

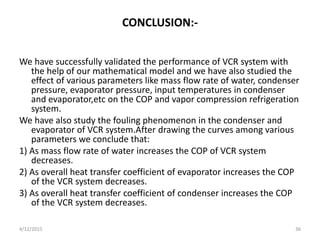

This document summarizes an experimental study on the impact of fouling on vapor compression refrigeration systems (VCRS). It describes the test rig setup, which includes thermocouples, a condenser, evaporator, display devices, stirrers, pressure gauges, expansion valve, compressor, and drier. It then provides properties of the refrigerant used, details the actual refrigeration cycle, and discusses various losses in VCRS. Mathematical calculations are shown for system components like the expansion valve, evaporator, compressor, and condenser. Graphs illustrate how COP, refrigeration effect, and compressor work vary with parameters like mass flow rate and heat exchanger U-values. The results are then compared to experimental data

![Fig No. 1 Refrigeration Test Rig [6]

4/12/2015 3](https://image.slidesharecdn.com/2ndprogressreport-150412125753-conversion-gate01/85/Impact-of-Fouling-on-VCR-System-3-320.jpg)

![Experimental setup description[6]

1-Thermocouples: Six thermocouples are used in our test rig.

The readings of the thermocouples are taken by knob by

rotating it .first thermocouple fit at outlet of the condenser.

Second and third thermocouples are fitted in the condenser

tank and evaporator tank respectively. And remaining

thermocouples are fitted in inlet water tank, inlet to

condenser and outlet to evaporator.

2-Condenser and evaporator: - as shown in the figurethe tub

and tube type condenser and evaporator are used in the kit

and the evaporator having insulator on it. These tanks contain

the two mechanicalagitators as shown in figure, for the

continuous mixture the water,the agitator can be controlled

by switch . These tanks have two valves at the lower side of

tanks for the water outlet. A copper tube is used for the flow

of the refrigerant in spiral form in the tub.

4/12/2015 4](https://image.slidesharecdn.com/2ndprogressreport-150412125753-conversion-gate01/85/Impact-of-Fouling-on-VCR-System-4-320.jpg)

![Fig No.2 Condenser[6]

4/12/2015 5](https://image.slidesharecdn.com/2ndprogressreport-150412125753-conversion-gate01/85/Impact-of-Fouling-on-VCR-System-5-320.jpg)

![Fig No.3 Evaporator[6]

4/12/2015 7](https://image.slidesharecdn.com/2ndprogressreport-150412125753-conversion-gate01/85/Impact-of-Fouling-on-VCR-System-7-320.jpg)

![Fig No.4 ACTUAL VAPOR COMPRESSION CYCLE [5]

4/12/2015 13](https://image.slidesharecdn.com/2ndprogressreport-150412125753-conversion-gate01/85/Impact-of-Fouling-on-VCR-System-13-320.jpg)

![Fig No.5 Schematic diagram of a simple refrigeration cycle and various

losses in VCR system. [5]

4/12/2015 14](https://image.slidesharecdn.com/2ndprogressreport-150412125753-conversion-gate01/85/Impact-of-Fouling-on-VCR-System-14-320.jpg)

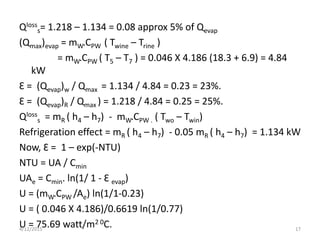

![MATHEMATICAL CALCULATION [6]

1.Expansion valve:

h6 = h7 , at P1 and T1, h1 = 297.1 kJ/kg from table,

at T6 = 40.8 and P6 = 1040 kPa , h6 = 109.7 kJ/kg from

table,

pressure loss in condenser = P1 – P6

= 1385.4 – 1040

= 345.4 kPa.

Ploss

cond = 25% of Pc

h6 =h7 = 109.7 kj/kg

4/12/2015 15](https://image.slidesharecdn.com/2ndprogressreport-150412125753-conversion-gate01/85/Impact-of-Fouling-on-VCR-System-15-320.jpg)

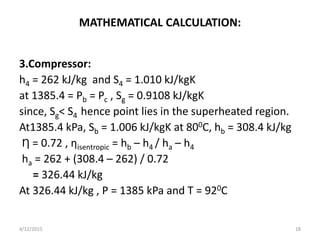

![MATHEMATICAL CALCULATION[6]

2.Evaporator :-

T7 = -6.90C, h6 =h7 = 109.7 kj/kg, P7 = 225.6 kPa

h7 = hf + x hfg at 225.6 kPa

109.7 = 42.51 + x(246.32 – 42.51)

x = 0.329

T4 = 10.30C, Pe = P4 = 170 kPa , h4 = 262.0 kJ/kg

Pressure loss in evaporator = P7 – P4 =55.6 kPa

Ploss

evap = 25% of Pevap

(Qevap) R = mR ( h4 – h7) = 0.008 (262 – 109.7) = 1.218 kW

(Qevap) W = mW.CPW . ( Two – Twin) = mw.Cpw (T5 –T3)

= 0.046 Х 4.186 (18.3 – 12.4) = 1.134 kW

4/12/2015 16](https://image.slidesharecdn.com/2ndprogressreport-150412125753-conversion-gate01/85/Impact-of-Fouling-on-VCR-System-16-320.jpg)